HDPE PP PE Compression Fittings and saddle 10 bar for water for irrigation system

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

China Manufacturer PP Compression fittings Irrigation Polypropylene PP Fitting COUPLING (1001) FEMALE COUPLING MALE COUPLING

Our PP compression fittings line has been designed for the conveyance of fluids at high pressures, for water conveyance, for potable water distribution and applications in the thermo-hydraulic sector. This product line is accordance with the most severe international standards in terms of mechanical properties and alimentary compatibilities.

Technical data

Materials

| Part | Material |

| Body(A) | Heterophasic block polypropylene co-polymer(PP-B) of |

| exceptional mechanical properties even at high temperature. | |

| Blocking bush(D) | Polypropylene |

| Nut(B) | Polypropylene with dye master of high stability |

| to UV rays andsolidity to heat( S grade according to standard DIN54004) | |

| Clinching ring(C) | Polyacetal resin(POM)with high mechanical resistance |

| And hardness | |

| O Ring gasket(E) | Special elastomeric acrylonitrile rubber(EPDM) for alimentary use |

| Reinforcing ring | AISI 430 (UNI X8Cr17,W,nr 14828)Stainless steel for female threads from 1”to 4” |

Working Pressures.

KEXING PP compression fittings allows the maximum working pressure(PN~PFA*) of 10 bar(UNI 9562) for diameters from 20mm to 63mm ,at the temperature of 20°C.

Maximum allowable working pressures related to the duration of pressure and temperature:

| Dn | PFA* | PMA* | PEA* |

| 20-63 | 16 | 20 | 24 |

| Temperature(°C ) | Da-10a25 | Da+26a+35 | Da+36a+45 |

| 20-63 | 16 | 20 | 24 |

Reference Standards

Dimensions: UNI 9561Working

Pressure: UNI 9562,DIN 8076-3,ISO 14236,BRL-K03.

Polyethylene(PE)pipes: UNI 7990,DIN 8074,UNI EN 12201

Threads: UNI ISO7/1,UNI EN 10026-1,ANSI ASME B1-20.1

Flanges: DIN 2501-1,UNI EN 1452-3.IS 7005-2

Size:

Our have two different style PP compression fittings for your choose

Certifications

CE GOST ISO14001 ISO9001

Trade Shows

We have attend more than 10 exhibitions each year.

Canton Fair / Chinaplas each year

Have been to Russia, Brazil, Chile,Argentina,Peru,Cupa,Austrialia,Indoneisa,Tailand, Burma, Vietnam,

Algeria, Morroco, Kazakhstan, Turkmenistan,Epypt,Spain,Poland,India, UAE, Turkey ,Singapore, and so on.

- Q: How do plastic pipe fittings differ from metal pipe fittings?

- Plastic pipe fittings differ from metal pipe fittings in several ways. Firstly, plastic fittings are generally more affordable compared to metal fittings. Additionally, plastic fittings are typically lightweight and easier to install, while metal fittings can be heavier and require more effort for installation. Plastic fittings are also resistant to corrosion and rust, which can be a concern with metal fittings. However, metal fittings generally have higher heat tolerance and are more durable in certain applications. Ultimately, the choice between plastic and metal fittings depends on the specific needs and requirements of the plumbing or piping system.

- Q: Are plastic pipe fittings suitable for use in power plants?

- Yes, plastic pipe fittings can be suitable for use in power plants depending on the specific requirements and applications. Plastic fittings can offer benefits such as corrosion resistance, cost-effectiveness, and ease of installation. However, it is essential to consider factors such as temperature, pressure, and the type of fluids being transported to ensure the suitability and durability of plastic pipe fittings in power plant environments.

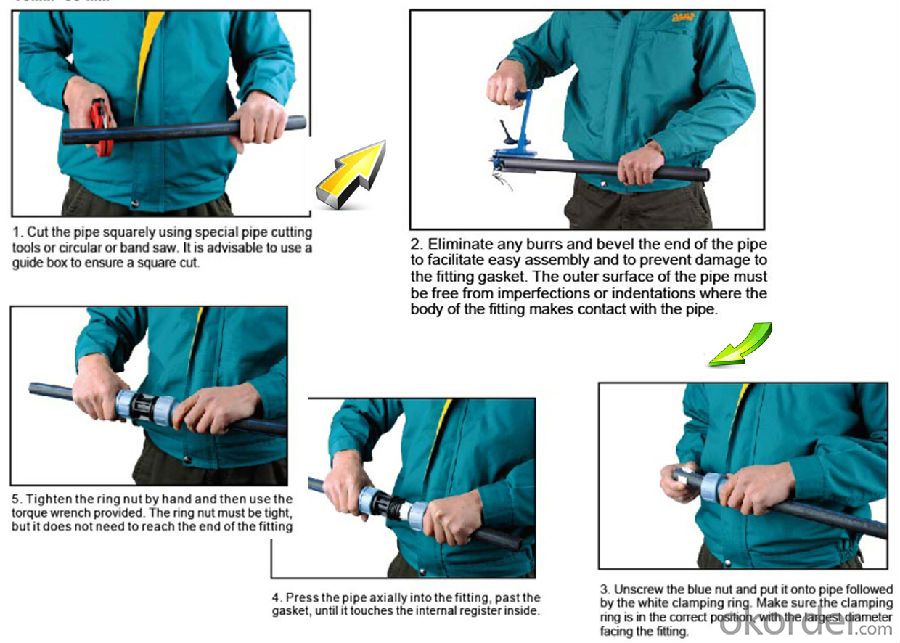

- Q: How do you connect plastic pipe fittings to PEX pipes?

- To connect plastic pipe fittings to PEX pipes, you can use push-fit or compression fittings specifically designed for PEX. Push-fit fittings require no tools and are simply inserted into the PEX pipe until they click in place. Compression fittings, on the other hand, involve tightening the nut over the fitting onto the PEX pipe with a wrench to create a secure connection.

- Q: Can plastic pipe fittings be used for hot water applications?

- Yes, plastic pipe fittings can be used for hot water applications. However, it is important to ensure that the plastic used is suitable for high temperatures and meets the necessary standards and requirements for hot water plumbing.

- Q: Can plastic pipe fittings be used for chemical processing systems?

- Yes, plastic pipe fittings can be used for chemical processing systems. However, it is important to select the appropriate type of plastic material that is resistant to the specific chemicals being processed. Different plastics have different chemical resistance properties, so it is crucial to choose the right material to ensure the fittings can withstand the chemicals and maintain system integrity.

- Q: Are plastic pipe fittings resistant to UV discoloration?

- Yes, plastic pipe fittings are generally resistant to UV discoloration.

- Q: Are plastic pipe fittings recyclable?

- Yes, plastic pipe fittings are recyclable. They can be collected and processed by recycling facilities to be transformed into new plastic products.

- Q: Can plastic pipe fittings be used for marine applications?

- Yes, plastic pipe fittings can be used for marine applications. They are often made from materials such as PVC (polyvinyl chloride) or CPVC (chlorinated polyvinyl chloride), which are resistant to corrosion and can withstand the harsh conditions of marine environments. Additionally, plastic fittings are lightweight, easy to install, and cost-effective, making them a popular choice for various marine applications such as plumbing systems, water supply, and drainage systems.

- Q: Are plastic pipe fittings compatible with push-fit connections?

- Yes, plastic pipe fittings are generally compatible with push-fit connections. Push-fit fittings are designed to be used with various pipe materials, including plastic pipes such as PVC or CPVC. They provide a secure and leak-free connection without the need for tools or soldering.

- Q: As long as the quality of plastic pipe is good Can the problem of plastic pipe connection be neglected?

- Only the performance of the pipe itself is not enough, the connection of plastic pipe is the largest local problem in pipeline system, especially the use of pipe connections, such as hot melt connection, no welding operation in accordance with the construction standard, extremely easy to cause hidden troubles due to leakage. General plastic pipe product standards are required to test the applicability of the system, can be selected according to the actual situation of the project inspection. Communicate further if you have any questions.

Send your message to us

HDPE PP PE Compression Fittings and saddle 10 bar for water for irrigation system

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches