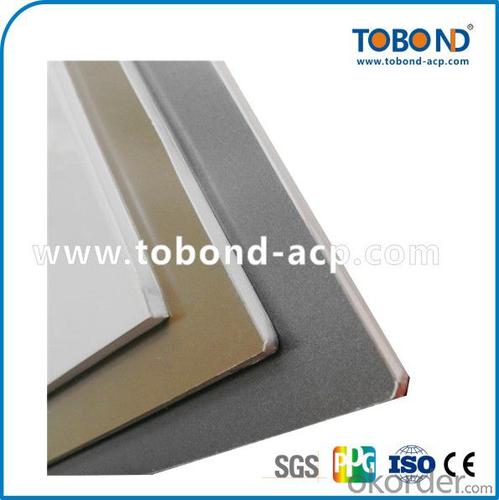

Grey coating outdoor aluminum panel TOBOND

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TOBOND PVDF ALUMINIUM COMPOSITE PANEL

TOBOND PVDF ALUMINIUM COMPOSITE PANEL

TOBOND PVDF plus Aluminium Composite Panel is special metal surface wall cladding material, compounded with superior aluminum and LDPE Plastic.

Comparing to traditional metal panel, TOBOND ACP is with prime performance of economic efficiency, environment friendly and flexible installation.

ADVANTAGES OF TOBOND ACP

Easy fabrication and installation.

Good Impact Resistance.

Good Smoothingness.

Various color and size for option.

TOBOND ACP Application

Outer wall cladding, curtain wall.

Redecoration of old buildings outer-wall.

Units wall cladding

Advertisement signboard

Kitchen and bath room ceiling

Industrial Usage, Vehicle bodies.

Color Chart:

STANDARD SIZE OF TOBOND ACP

Series | Coating | Usage | Panel Thickness | Panel Size(mm) |

PVDF Plus Outdoor Panel | PVDF | Exterior Wall Cladding | 4mm /3mm | 1220*2440 1220*2900 |

Indoor panel | Polyester | Interior Decoration/ Advertisement board | ||

Fireproof panel | PVDF/Polyester | Exterior Wall Cladding/Interior Decoration |

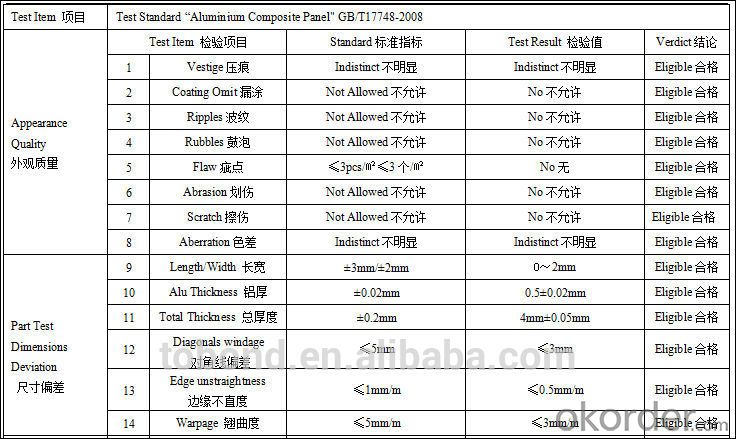

TEST REPORT FOR TOBOND ALUMINIUM COMPOSITE PANEL

|

Proceeding Noticed

Portage: panel must be uplifted with its four borders at the same time during portage, do not drag and whop for fear scraping surface of the panel.

Notching; if notching with notching equipment or gong equipment, using milling cutter with half round head≥90 degree. When notching, pls leave 0.2—0.3mm thickness plastic core materials bending with aluminium sheet to increase intension and tenacity, otherwise aluminium sheet may rupture or coating crack.

Bending: forcing equably when bending, molding one-off, do not bend again and again, or Aluminium panel may rupture.

Batch: same color panel from different batches may have chromatic aberration, contrast process of chromatic aberration should be added if selling or using panels with different batches panels. Panels can be placed on a plane only there may be visual chromatic aberration.

Cleaning: clear the panel with water, scours or alcohol over98% with soft sponge. Do not use Chemical Solvents.

- Q: How to open the aluminum plate

- In the aluminum plate above the hole is actually a relatively simple process, with the same drill or slot machine like the same micro-electric equipment can be achieved. You can first pierce in the center, and then set the peripheral lines, and then cut off along the lines with electric saws

- Q: Dry hanging stone, aluminum-plastic board two kinds of external wall decoration use and maintenance costs, investment costs, the applicability of the two materials decorative effect construction speed

- Dry hanging stone, the use of aluminum-plastic plate is no standard, depends on your choice of materials. Maintenance costs should be different. The cost of investment is also to look at your material choices. Dry hanging stone for the building of the podium, the height is best not too high. Aluminum-plastic panels can be relatively high point, belonging to the modern style type.

- Q: What are the benefits of aluminum-plastic board prices?

- Aluminum composite panel (also known as aluminum-plastic plate) as a new type of decorative materials, since the late eighties of the last century from the early 1990s from South Korea and Taiwan to China, with its economic, optional color diversity, Convenient construction methods, excellent processing performance, excellent fire resistance and noble quality, quickly by the people of all ages. Throughout the building of a new building, it is not difficult in the meantime to find its traces. There may be some aluminum-plastic board after the completion of works, ranging from three or two months, as many as a year or so, there have been quality problems, so that many owners feel a headache. Here on the composition of aluminum-plastic panels, applications, simple assembly and assembly methods and common quality problems to do some superficial analysis.

- Q: Astella aluminum plate 3 plywood price how much ah?

- 3% thick inside the board there are a lot of aluminum thickness,

- Q: Sub-white aluminum-plastic door with a white aluminum side, how? The effect is good?

- The easiest way is to directly on the white aluminum-plastic plate directly attached to a layer of black aluminum plate. Since you have done aluminum-plastic board layer, that grass-roots flatness should not be a problem! We often do shop strokes, spray paint with the car, will not fall, the premise is to clean up the original level, remember that is spray, not brush.

- Q: White aluminum plate can be a new brush color? Store white aluminum-plastic board for a long time dirty, you can buy a new paint back to brush it?

- If the quality of the white aluminum plate is poor, it is hard to scrub clean for a long time.You can buy a polyester paint ...

- Q: Not clear, and we help me say the difference between them, advantages and disadvantages

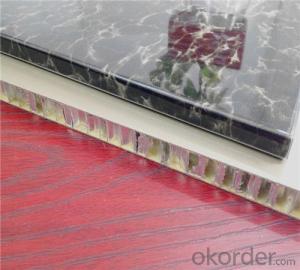

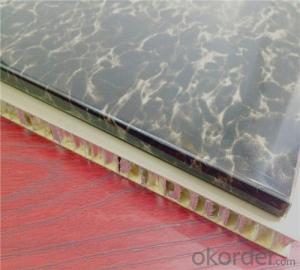

- Aluminum plate is made of aluminum as the general specifications of the 300X300MM box is generally used for kitchen bathroom ceiling. Aluminum-plastic plate is a layer of two layers of aluminum plate made of a layer of plastic specifications generally 1220X2440X4MM rectangular box. Made arc is generally used for the external walls and the door and the complex corner of the decorative cylinder

- Q: What is a composite function building material?

- Aluminum-plastic composite board is a chemically treated coated aluminum sheet for the surface material, with polyethylene plastic as the core material, in the special aluminum-plastic plate production equipment from the processing of composite materials.

- Q: What is the size of the general aluminum-plastic board?

- Aluminum plastic board common specifications are 1.22Mx2.44M, thickness of 3-5MM, single and double-sided, according to the thickness of aluminum and eight silk -30 silk and other specifications, according to the use of indoor And outdoor use two, as well as polyester plate and carbon plate of the points, if the outdoor plate can be customized, the longest can be 6M long.

- Q: What is the main purpose of aluminum-plastic composite panels?

- The main purpose of aluminum-plastic composite panels is used for building curtain walls and architectural interior and exterior decoration. The development of aluminum-plastic panels mainly in the construction industry, building decoration industry-based.

Send your message to us

Grey coating outdoor aluminum panel TOBOND

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords