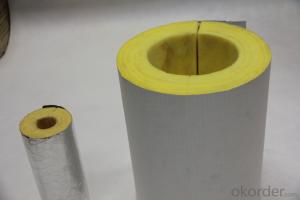

Glass Wool Insulated Aluminum Foil Faced Pipe/Tube

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

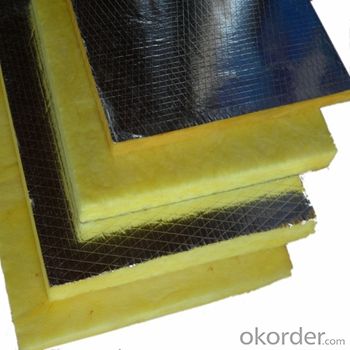

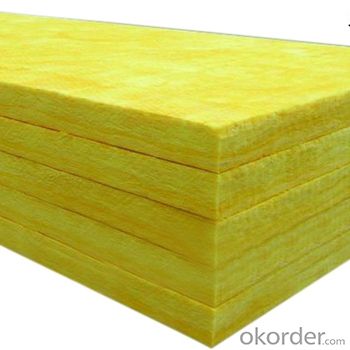

1. Glasswool Description

Glasswool board is the unearthly sound absorbing and warm keeping material. It has been widely applied for heat insulation of house wall, compartment; temperature keeping of computer rooms, refrigerator; denoise of power plants and pump rooms; adjustment of Hi-fi etc.

This special cell structure means that the sheet doe’s not conduct heat. When you lay XPS boards as an underlay any heat from your room or floor will be reflected back towards the floor surface. As you will not be wasting heat through your floor you will utilize your energy in an effective manner and thereby lower your energy consumption and carbon footprint.

2. Main Features

1. Excellent thermal insulation

2. High compressive strength of excellence

3. High-quality water-repellent, moisture resistance

4. Energy saving and environmental protection

5. Excellent heat preservation and insulation

3. Scope of application

It is widely used for heat insulation and sound absorption in industrial workshops, Prefab houses, Portable cabins, warehouses, public facilities, exhibition centers, shopping malls, and a variety of indoor playgrounds, sports stadiums and etc

4. Glasswool Images

5. Glasswool Specification

density(kg/m3) | width(mm) | thickness(mm) | length(m) | packing/roll Vacuum package | |

10-48 | 1200 | 25-150 | 10-30m | 2roll | |

10-48 | 1200 | 25-150 | 10-30m | 1roll | two-roll overlapping |

10-48 | 1200 | 25-150 | 10-30m | 1roll | two-roll overlapping |

10-48 | 1200 | 25-150 | 10-30m | 1roll | two-roll overlapping |

10-48 | 1200 | 25-150 | 10-30m | 1roll | two-roll overlapping |

6. FAQ

(1) How about your company?

A world class manufacturer & supplier of glasswool and is one of the large scale professional investment glasswool bases in China. Annually more than 1000 containers of glasswool are exported to markets in Europe, America and Japan.

(2)What is the storage condition?

The products should be stored at room temperature and kept from wet and heat source.

The user should take test and do trial application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

(3) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

(4) How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served

- Q: If the glass wool is used for thermal insulation outside seamless steel tube, should the pipe be rust-proof and sprayed paint?

- That depends on the requirements. Brushing paint is needed. I an engaged in thermal insulation material wholesale and construction (see name).

- Q: What are the uses of glass wool thermal insulation materials?

- They are generally used in steel roofing. and the outer layer of pipes. .

- Q: What kind of glass wool pipe is this? Where is it sold?

- I own a glass wool plant and you can contact me if you need something.

- Q: Which is more effective in retarding fire, rock wool or glass?wool? What is the difference between rock wool and glass wool?

- In terms of fireproof effect, rock wool is certainly better than glass wool. The maximum temperature of rockwool is 1100 ℃, and glass wool is only 600 ℃. In addition if used in the external walls, the highest unit weight of glass wool can only be in the range of 60-90, but rock wool can be over 140. Generally glass wool can not be used in external wall at present. Only rock wool is A grade fireproof material.The heat conductivity coefficient of glass wool is lower than glass wool and the fibre length of rock wool is longer than glass wool. As for price, tons of glass wool rock is more expensive than that of rock wool. However, if counted by square size, glass wool is cheaper per square size than rock wool.

- Q: what's the differences between glass wool roll mat and rock wool roll mat? does glass wool roll mat have any mandatory retest requirements or environmental requirements?

- Steel structure roof basically uses glass wool roll mat, because rock wool roll mat is six to ten times heavier than glass wool roll mat, light steel frame can't bear so much gravity, glass wool is more fluffy than rock wool, so it's thermal insulation effect is better, glass wool is cheaper than rock wool, the glass wool fire rating is A-level flame retardant, now people won't use the rock wool blanket, wall thermal insulation used rock wool board.

- Q: Where are the differences between the glass wool board and glass wool blanket?

- Glass wool felt is generally used to the top of industrial plants, which is roll-like; glass wool board is mainly used for external wall heat insulation, which is board-shaped.

- Q: Which thermal insulation materials are the best for air-conditioners? Is it rubber and plastic, PEF or glass wool?

- Copper contains rubber and plastic. PEF and glass wool are both suitable, but glass wool is not recommend for its poor waterproofing performance, you'd better use rubber and plastic! You can select them with appropriate thickness according to your local winter temperature, or else it will be frozen in winter for it is too thin.

- Q: Whether the rigid section of aluminium foil glass wool can be twined with glass fiber cloth

- This is not necessary, it depends on the place the shell is used, the best thing is to add a layer of insulation tape.

- Q: Is glass wool felt the mineral wool felt?

- No.

- Q: The main application of glass wool

- As long as it is pipes that needs to be insulated.

Send your message to us

Glass Wool Insulated Aluminum Foil Faced Pipe/Tube

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords