Geotextile Filtration Membrane Complex Earthwork Material Compound

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product description

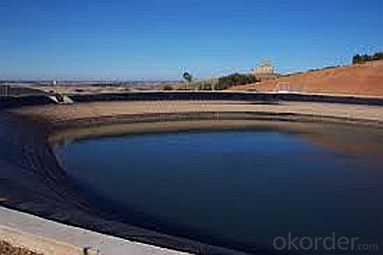

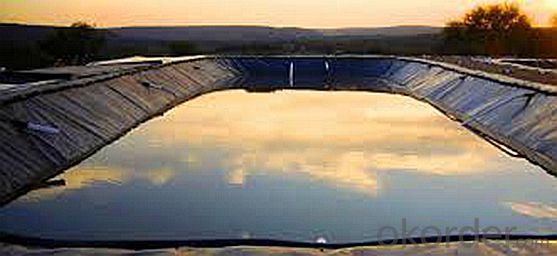

HDPE waterproofing membranes use finest HDPE resin as raw material, they were made of inflation method and advanced automatic equipments, all the products are produced and inspected according to and complied with ASTM standard, CJ/T234 2006, GB/T17643 1998, etc.

They are complete in specifications: double smooth surface, double rough surface and single rough surface. The widest broad width can reach 8M, the thickness if 0.1 to 3.0mm.

Detailed Images

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the quality control measures for geotextile manufacturing?

- Quality control measures for geotextile manufacturing include conducting regular inspections throughout the production process to ensure that the geotextiles meet specified standards. This involves checking the raw materials used, monitoring the manufacturing equipment for proper functioning, and conducting tests on the finished products to assess their strength, durability, and other performance characteristics. Additionally, quality control measures may involve implementing standard operating procedures, conducting routine quality audits, and adhering to relevant industry and regulatory guidelines.

- Q: How do geotextiles affect visual aesthetics?

- Geotextiles can have both positive and negative effects on visual aesthetics. On one hand, they can enhance the visual appeal by providing a clean and uniform appearance, especially when used in landscaping or erosion control. On the other hand, geotextiles can sometimes be visible and disrupt the natural beauty of a landscape, particularly when used in areas where they are not well integrated or when they deteriorate over time. Therefore, the visual impact of geotextiles depends on their proper installation, maintenance, and suitability for the specific application.

- Q: 200g / m2 geotextile how to enter the inspection test

- 200g / m2 geotextile how to enter the inspection test

- Q: What glue can clay stickers glue?

- Geotextiles generally do not need to glue glue, because the geotextile is made of polyester staple fiber acupuncture, the product itself has a lot of small pores, the use of glue bonding not only a waste of glue, bonding effect is not good. Geotextile in the project is generally used in the hand-type sewing machine suture, suture geotextile not only glue glue than the geotextile solid and reliable, and the construction of geotextile suture is also much higher than the construction of glue with geotextile Speed, while the cost of sewing geotextile is also much lower than the cost of glue bonding geotextile. Generally in the project to play the effect of impervious geomembrane, composite geomembrane (also known as composite geotextile) can use glue bonding. Adhesive glue can be purchased in the geomembrane manufacturer, of course, you can also buy in the local building materials market, waterproof plastic or KS geomembrane special glue. These two glue can also be used to bond geotextiles.

- Q: Can geotextiles be used for drainage purposes?

- Yes, geotextiles can be used for drainage purposes. They are often used to enhance the drainage capacity of soil by allowing water to flow through while preventing soil erosion. Geotextiles can be employed in various applications such as road construction, landfills, and agricultural fields to improve drainage and prevent waterlogging.

- Q: Can geotextiles be used in bridge abutment reinforcement?

- Yes, geotextiles can be used in bridge abutment reinforcement. Geotextiles are commonly used in civil engineering applications to enhance the stability, strength, and durability of various structures, including bridge abutments. They can provide soil confinement, prevent erosion, and improve the overall performance of the abutment by distributing loads and reducing settlement.

- Q: How do geotextiles help with soil separation in railway ballast systems?

- Geotextiles help with soil separation in railway ballast systems by preventing the mixing of different layers and ensuring the stability of the ballast. They act as a barrier between the ballast and subgrade, preventing the migration of fines from the subgrade into the ballast layer. This separation helps maintain the structural integrity of the railway track, reducing the risk of settlement and track deformations. Geotextiles also enhance drainage by allowing water to flow freely through the ballast layer, preventing waterlogging and maintaining the overall stability of the track.

- Q: How do geotextiles improve the performance of geogrids?

- Geotextiles improve the performance of geogrids by providing additional reinforcement and stability. They act as a separation layer, preventing soil particles from migrating through the geogrids and reducing the potential for clogging. Geotextiles also enhance the drainage capacity of geogrids by allowing water to flow freely through the system, preventing the accumulation of water and reducing the risk of soil erosion. Moreover, geotextiles can increase the overall strength and load-bearing capacity of geogrids, making them more efficient in stabilizing soil and improving the overall performance of geogrid applications.

- Q: Can geotextiles be used for reinforcement of road embankments?

- Yes, geotextiles can be used for reinforcement of road embankments. Geotextiles are commonly used in civil engineering projects to improve the stability and performance of road embankments. They can effectively distribute loads, increase soil shear strength, and prevent soil erosion, offering a reliable and cost-effective solution for road reinforcement.

- Q: How do geotextiles contribute to the performance of geogrid-reinforced slopes?

- Geotextiles play a crucial role in enhancing the performance of geogrid-reinforced slopes. They provide separation and filtration functions by preventing the mixing of different soil layers and allowing water to drain through while preventing the loss of fine particles. This helps to maintain the integrity and stability of the slope, reducing the risk of erosion and soil movement. Additionally, geotextiles act as a barrier to vegetation growth, minimizing the potential damage caused by roots. Overall, geotextiles significantly contribute to the long-term effectiveness and durability of geogrid-reinforced slopes.

Send your message to us

Geotextile Filtration Membrane Complex Earthwork Material Compound

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords