Geogrids Price HDPE Uniaxial Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Corrosion HDPE Uniaxial Geogrid Description:

Corrosion Resistant Fiberglass Geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after surface covering own the favorable property of alkali resistance and aging resistance.

Main Features of HDPE Uniaxial Geogrid:

HDPE Uniaxial Geogrid It is used widely to increase the asphalt road surface, concrete road and roadbed (both soft and hard road surfaces).

HDPE Uniaxial Geogrid could Prevent road collapse and crack

HDPE Uniaxial Geogrid maninly applied in strengthen soft ground of rail and road

Could replace steel-plastic geogrid in coal mine.

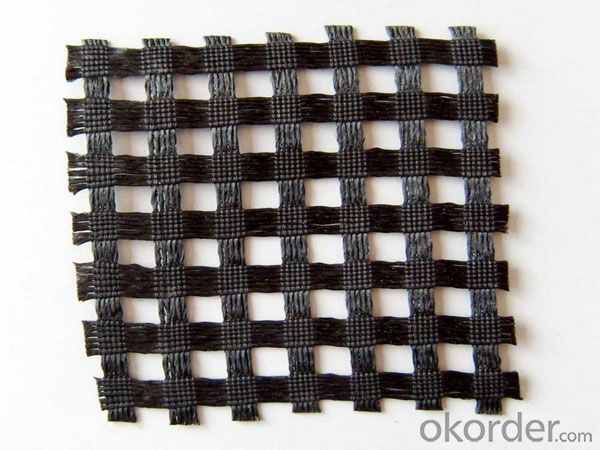

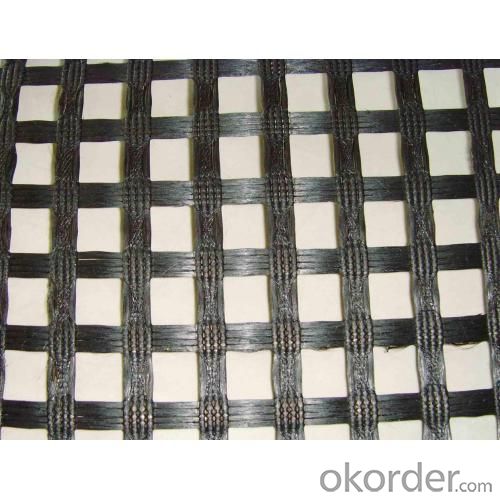

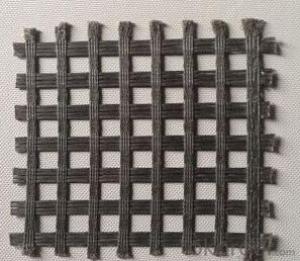

HDPE Uniaxial Geogrid Images

HDPE Uniaxial Geogrid Specification:

| Specification | EGA30-30 | EGA50-50 | EGA80-80 | EGA100-100 | EGA120-120 | ||

| Mesh size(mm) | 25.4×25.4or12.5×12.5 | ||||||

| Breaking strength≥(KN/m) | Warpdirection | 30 | 50 | 80 | 100 | 120 | |

| Across warp | 30 | 50 | 80 | 100 | 120 | ||

| Elongation at break≤(%) | Warp direction | 3 | |||||

| Across warp | 3 | ||||||

| Elasticity modulus(GPA) | 67 | ||||||

| Thermal tolerance() | -100~280 | ||||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: Can geogrids be used in mining tailings containment?

- Yes, geogrids can be used in mining tailings containment. Geogrids are often used in mining operations to reinforce and stabilize containment structures, such as tailings dams, due to their high tensile strength and ability to distribute loads. They help prevent slope failures and erosion, improving the overall stability and longevity of tailings containment systems.

- Q: Especially in the curtain wall project

- There are plastic grille and glass fiber grille (fiberglass), as well as Geotextile

- Q: What are the quality assurance measures for geogrid installation?

- Quality assurance measures for geogrid installation include: 1. Proper preparation of the subgrade: Ensuring that the subgrade is well-graded, compacted, and free from any debris or vegetation is crucial before geogrid installation. This ensures a stable base for the geogrid and enhances its effectiveness. 2. Correct geogrid selection: Choosing the appropriate type and strength of geogrid based on the specific project requirements and design specifications is essential. This involves considering factors such as load capacity, soil type, and expected performance. 3. Accurate geogrid placement: Ensuring that the geogrid is correctly positioned and securely anchored is vital for its effectiveness. Careful attention should be paid to the alignment, overlap, and anchorage of the geogrid to prevent any shifting or displacement during and after installation. 4. Proper tensioning: Geogrids need to be adequately tensioned to achieve the desired tensile strength and load distribution. This requires following manufacturer guidelines and using appropriate tensioning equipment to achieve the recommended elongation or strain. 5. Regular inspection and testing: Conducting frequent inspections during geogrid installation helps identify any defects, damage, or non-compliance with specifications. Additionally, conducting pull-out tests or other relevant performance tests can verify the geogrid's adherence to the desired strength and load-bearing capacity. 6. Documentation and record-keeping: Maintaining comprehensive documentation of geogrid installation, including materials used, installation procedures, test results, and any deviations or corrective actions taken, ensures traceability and accountability. This documentation can be valuable for quality control and future reference. By implementing these quality assurance measures, geogrid installation can be carried out effectively, ensuring the desired performance and longevity of the geogrid system.

- Q: meters. Material: tgsg. This section of subgrade for soft soil foundation (water) what is the purpose and principle of this treatment? Seeking answers experienced master change, or in the design the unit did. Thank you. Do a detailed description of indebted forever. My understanding is...Geogrid width of 3 meters, the berm soil subgrade body laying 1.4 meters, laying 1.6

- The main purpose of filling subgrade is to use geogrid, which is to prevent the longitudinal cracking and sliding. As for Geogrid, it can not directly stabilize the slope, but also rely on geotextile wrapped. As for the soaking embankment, in addition to the use of Geogrid and geotextile, but also consider the problem of slope protection (such as stone, concrete surface etc.).Geogrid is usually used to fill the embankment with high height, in order to play a role. Also, you said that the protection of the ramp laying 1.4 meters, the laying of the roadbed in the area of 1.6 meters, these are trivial, can only play a part of the role of little. See you use the material is plastic geogrid, this is the worst kind of material, the strength is very low. Small size, low strength, not as good as the use of woven bags stacked slope. I guess this is a low grade road

- Q: Are there any limitations or drawbacks of using geogrids?

- Yes, there are some limitations and drawbacks of using geogrids. One limitation is that geogrids can be relatively expensive compared to other soil stabilization methods. Additionally, the installation process of geogrids can be time-consuming and requires skilled labor. Another drawback is that geogrids are not suitable for all types of soil and geological conditions. They may not be as effective in cohesive soils or in areas with high water table levels. Moreover, geogrids have a limited lifespan and may require regular maintenance or replacement over time.

- Q: What are the design considerations for geogrid-reinforced structures?

- Some design considerations for geogrid-reinforced structures include the type and strength of the geogrid material, the soil characteristics and conditions, the required structural integrity and stability, the anticipated loads and stresses, the desired lifespan of the structure, and the overall cost-effectiveness of the design. Additionally, factors such as installation and construction techniques, environmental impacts, and local regulations may also need to be taken into account during the design process.

- Q: Can geogrids be used in mining tailings management?

- Yes, geogrids can be used in mining tailings management. Geogrids are commonly used in the mining industry to reinforce soil and stabilize slopes. In the context of tailings management, geogrids can be used to improve the stability and strength of tailings dams or containment structures, preventing erosion and potential environmental hazards. Additionally, geogrids can enhance the consolidation and dewatering of tailings, facilitating their proper management and reducing the risk of environmental contamination.

- Q: What are the testing methods for geogrids?

- The testing methods for geogrids typically involve evaluating their tensile strength, aperture size, junction strength, and creep characteristics through laboratory tests such as wide-width tensile strength test, puncture test, junction efficiency test, and long-term creep test. These methods help determine the geogrids' performance and suitability for various soil stabilization and reinforcement applications.

- Q: Can geogrids be used in seismic zones?

- Yes, geogrids can be used in seismic zones. Geogrids are commonly used in geotechnical applications to reinforce soil and improve stability. They can help increase the resistance to lateral spreading and reduce the potential for damage caused by earthquakes in areas with active seismic activity. However, it is important to consider the specific design requirements and consult with engineers experienced in seismic design to ensure the proper selection and installation of geogrids in these zones.

- Q: Can geogrids be used in road construction?

- Yes, geogrids can be used in road construction. Geogrids are commonly used in road construction to reinforce the pavement layers and improve the overall strength and stability of the road. They help to distribute the load more evenly, reduce the potential for cracking and rutting, and enhance the lifespan of the road.

Send your message to us

Geogrids Price HDPE Uniaxial Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords