Geocells Market - PVC Coated Polyester Geogrid Warp Knitting for Railway

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Type: | Geogrids | Place of Origin: | Shandong, China (Mainland) | Brand Name: | CMAX

|

Model Number: | polyester geogrid | Material: | Polyester | note: | plastic geogrid |

tensile strength: | 15,20,25,30,40,50,60,70,80,90,100,110,120 and so on | mesh size: | 36mm*36mm | roll size: | 3.95*100m or 3.95*50m |

certificate: | CE ISO |

Packaging & Delivery

Packaging Details: | plastic geogrid packing in roll or customized |

Delivery Detail: | 5 days |

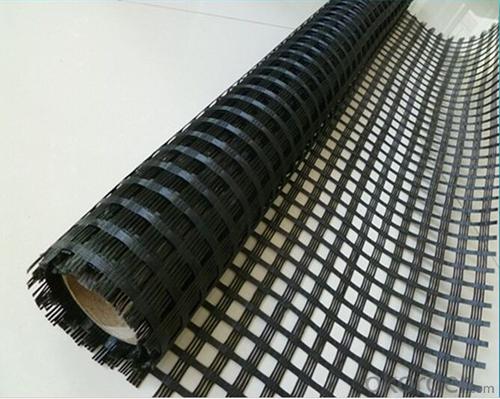

Reinforcement Polyester Geogrid :

(Warp Knitted Polyester Geogrid) :

Size | PET30/30--PET400/400; PET40/30--PET600/30 |

Price:FOB QINGDAO PORT | USD 0.3/Sq.m -- 5.0/Sq.m (LARGER QUANTITY WITH NICE PRICE) |

Packing in Roll

|

Roll width 3.95 Meter, 168 rolls in one 40HC Container.

|

Tensile strength at break | 30kn~600kn |

Stretching ratio | 13% |

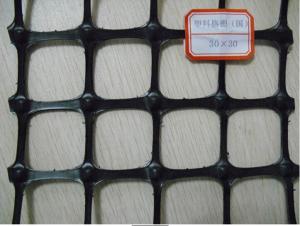

Grid size | 12.7*12.7mm, 25.4*25.4mm, 50.8*50.8mm |

Mesh size | 9*9mm, 20*20mm, 35*35mm |

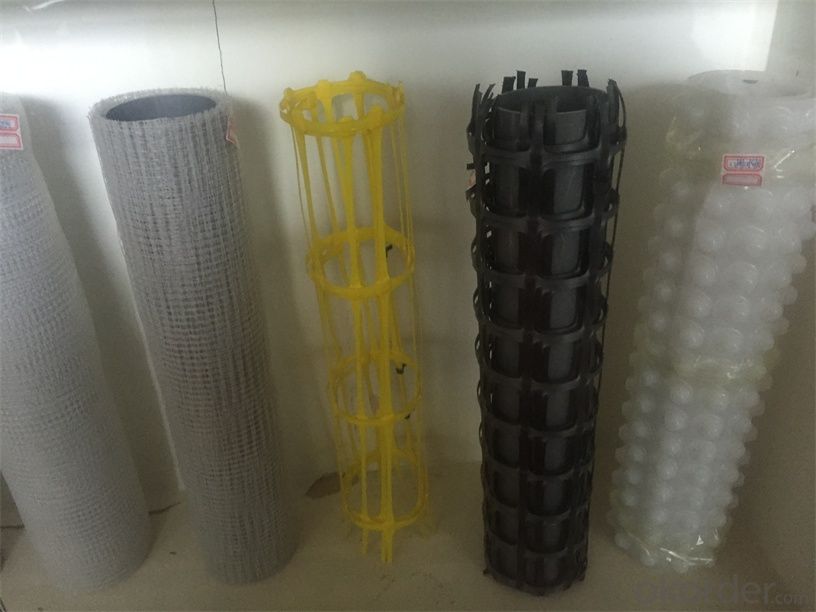

Roll width | 1.5m, 2m,3m,3.95m,5.8m |

Roll length | 50m, 100m |

Coating | PVC |

40HC container: | about 20000 Sq.m --50000 Sq.m |

Customize: | You can get more than what you pay for. Min 10000Sq.m |

Place of Origin | SHANDONG DAGENG, TAIAN CITY, SHANDONG, CHINA. |

Certificate | ISO ,CE |

1. Product introduction:

High strength polyester filament warp knitting geogrid select high strength synthetic fiber as raw material,adopt warp knitting oriented structure,and no curving between latitude and longitude fiber,use high strength filament on the intersection point to form firm bonding point,and fully perform the mechanical property.

2.Product features:

High strength polyester filament warp knitting geogrid possesses the characters of high intensity high module low creep deformation anti-aging anti-embrittlement high tensile strength big anti-peel strength strong binding force with soil and crushed stone and pre-design property and so on.

3. Application range:

1).Enhancement of soft roadbed of each kind of high grade road and railway,isolate different base material

2).Strengthen and stable river and slope of embankment.

3).Strengthen and stable each kind of base.

4).Strengthen the bridge and road surface.

FAQ

1. Can you send samples to us ?

Yes , free samples could be provided , but customer need pay for the freight cost .

After order placed , the freight charge could be refund .

2. What’s your Payment term ?

T/T , L/C , Western Union,Paypal ...

3. What’s your delivery method ?

By sea , By train , etc

4. What's your MOQ quantity ?

MOQ is one 20'container , the quantity could be negotiable

- Q: What is the role of geogrid?

- What is the role of geogrid? The geogrid is divided into: plastic geogrid, glass fiber geogrid, warp knitted polyester geogrid, steel plastic composite geogrid and polyester fiber warp knitting geogrid. The geogrid is used as reinforcement of reinforced earth structure or reinforced material. So what is the role of geogrid? The geogrid plays a very important role in the road, mainly strengthening subgrade and aging. The following is a detailed introduction

- Q: Bi directional plastic geogrid is suitable for engineering

- Applicable to all kinds of embankment and roadbed reinforcement

- Q: Can geogrids be used in coastal erosion control projects?

- Yes, geogrids can be used in coastal erosion control projects. Geogrids are commonly used to stabilize soil and prevent erosion by providing reinforcement and structural support. In coastal areas, where erosion is a significant issue, geogrids can help to stabilize slopes, retain soil, and protect coastal infrastructure from the impact of waves and tides.

- Q: Are geogrids suitable for use in high groundwater conditions?

- Yes, geogrids are suitable for use in high groundwater conditions. Geogrids are commonly used in civil engineering applications, including in areas with high groundwater levels. They are designed to provide soil stabilization and reinforcement, even in challenging conditions such as high water tables. Geogrids have excellent drainage properties and are resistant to water, making them a reliable solution for projects in high groundwater conditions.

- Q: Can geogrids be used in soft soil conditions?

- Yes, geogrids can be used in soft soil conditions. Geogrids are often used in such conditions to improve the stability and load-bearing capacity of the soil. They are designed to provide reinforcement and prevent soil movement, making them an effective solution for soft soil conditions.

- Q: What is the market price of the geotechnical grid in 2017

- (3) geogrid, geogrid laying bottom surface should be smooth, dense, should generally be tiled, straight, no overlap, no curl, kink, two pieces of geogrid adjacent to lap 0.2m, and along the horizontal Subgrade of geogrid overlap every 1 meters with 8 wire were interspersed in the grid connection, and laying on every 1.5-2m U nail is fixed on the ground.

- Q: Can geogrids be used in reinforced slopes?

- Yes, geogrids can be used in reinforced slopes. Geogrids are often used to enhance the stability and strength of slopes by providing reinforcement and preventing soil erosion. They are commonly used in various engineering applications, including reinforced slopes, to improve slope stability and increase load-bearing capacity.

- Q: What is the typical geogrid roll weight for specific applications?

- The typical geogrid roll weight for specific applications can vary depending on factors such as the type of geogrid, the intended use, and the desired strength requirements. However, geogrid rolls commonly range from 50 to 150 pounds for standard applications.

- Q: Are there any design guidelines for using geogrids in reinforcement applications?

- Yes, there are design guidelines available for using geogrids in reinforcement applications. These guidelines provide recommendations for selecting the appropriate geogrid type, determining the required strength and stiffness properties, and specifying the proper installation methods. The guidelines also outline factors such as soil characteristics, loading conditions, and project requirements that need to be considered in the design process. Adhering to these guidelines ensures the effective and efficient use of geogrids in reinforcement applications.

- Q: What criteria should be used in the construction of Geogrid

- 1, the construction site: requirements compaction flat, horizontal, removal of the protrusion. 2, in the formation of compaction: Geogrid laying site, installation of the grid the main stress direction (longitudinal) should be perpendicular to the axis of the embankment, laying should be smooth, no wrinkles, as far as possible tension. With the plug pin and the earth pressure is fixed, the laying of the grille main stress direction is best long without joint connection between the amplitude and the amplitude of the manual banding lap, lap width not less than 10cm. If the grid is set above two layers, the seam should be staggered. After laying a large area, the overall adjustment of its flatness. When the cover of a layer of soil, not rolling before, should be used manually or machine tensioning grid, the strength should be uniform, so that the grid in the soil for the tension state. 3, the choice of packing: packing should be selected according to the design requirements. Practice has proved that, in addition to frozen soil, swamp soil, domestic waste, chalk, diatomite can be used as filler. However, the mechanical properties of gravelly soil and sandy soil are stable, and the water content is very small. Packing size should not be greater than 15cm, and pay attention to control the packing gradation, to ensure the compaction weight. 4, the packing of the paving and compaction: when the laying of the grid positioning, should be filled in a timely manner, the exposure time shall not exceed 48 hours, can also take the side of the laying of the backfill flow shop. First spread the filler at both ends, the grid will be fixed, and then to the central propulsion. Rolling sequence is the first two sides after the middle. When the roller compaction can not directly contact with the reinforced material, the non compacted reinforcement generally do not allow the vehicle to travel on the above, so as to avoid the dislocation. The degree of compaction is 20-30cm. Pressure...

Send your message to us

Geocells Market - PVC Coated Polyester Geogrid Warp Knitting for Railway

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords