Gabion Box in Military/ Hesco Bastion/ Welded Gabion Box

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

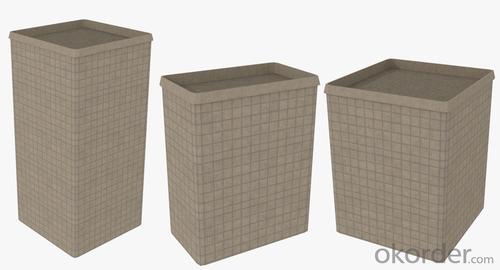

Hesco barrier is gabion-like. It is a combination of welded wire mesh frame outside and non-woven geotextile liner inside. Sand, soil, gravel and blinding are frequently used as filling because of geotextile liner.

Gabion bastions are mainly used in military and flood control for its modular structure and quick setup. For military, a gabion Hesco with 24 inches thickness can stop rifle bullets, shell fragments and other shrapnel. While for flood protection, gabion Hesco can be assembled soonest and come into use.

HESCO products have been used in many countries around the world including Afghanistan, Iraq, Bosnia, Kosovo, Yemen, Sri Lanka, Jordan, UAE and Turkey. Most military organizations currently use HESCO products including the US Army, UK MOD, USMC, USAF and NATO.

In addition to the standard Container unit, HESCO is constantly developing its portfolio of products in response to its customers' requirements. Multi-cellular wall system force protection product

HESCO container applications:

HESCO Basion In Military

HESCO Barrier In Humanitarian

HESCO Blast Wall In Humanland Security

Military Bastion Barrier In Civil Engineering

HESCO Technical Information

1. HESCO Blast Wall

HESCO Blast Wall (also named HESCO bastion, HESCO barrier) has been on hand to aid civil engineers with a wide range of environmental issues for over 10 years. Originally designed to combat the effects of coastal erosion, HESCO Bastion Container has since been used extensively throughout the world for other civil engineering applications.

The versatility of a HESCO Barrier Container structure enables it to be used across a variety of applications such as coastal erosion, flood protection, river and bank stabilisation, retaining walls, land reinforcement and soil conservation.

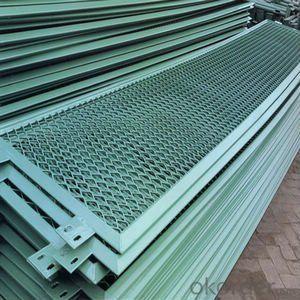

A galvanized steel unit lined with geotextile fabric, HESCO Barrier Concertainer is completely assembled during manufacture, ensuring rapid installation. Available in a wide range of sizes, units can be joined and extended using the provided joining pins. The primary advantage of the product is its ability to utilise locally available fill material to rapidly construct walls and other structures with minimal manpower and resources.

2. HESCO Container

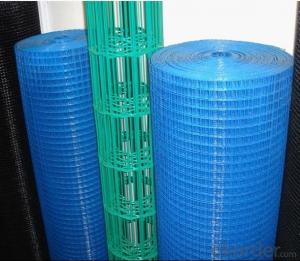

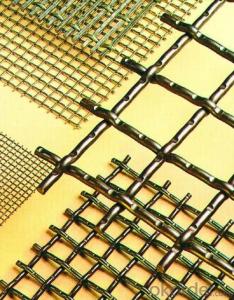

The Container unit is a multi-cellular wall system manufactured from welded Zinc-Alu coated steel wire mesh and joined with vertical, helical coil joints. The units are lined with heavy-duty non-woven polypropylene geotextile.

The Container unit's primary advantage over other force protection systems is its ability to utilize locally available fill material to rapidly construct defensive barriers and other structures with minimal manpower and resources.

Units can be extended and joined together to provide effective and economical structures tailored to the specific threat and level of protection required. Container units are available in a variety of different sizes and delivery systems.

Hesco barrier structure

Similar to beehive, Hesco barrier is comprised of external welded gabion and interior fabric liner. Its content includes soil, sand or little stone. The line would be yellow, grass green or other colors which blends well with the surroundings.

Joining pins are supplied to join units together. Plastic ties are supplied to close the geotextile together at the top of unit ends, which prevents fill material from falling between unit joints.

General specifications:

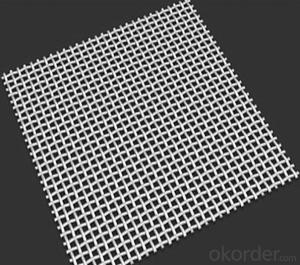

Geotextile lined welded wire fabric gabion to ASTM A 974-97.

Welded Mesh, coils and pins

The Concertainer units are manufactured with a Alu-Zinc coated welded wire mesh. The mesh has a spacing of 3" x 3" and a wire gauge of 8.5 American SWG, steel/diameter of 0.155"/3.937mm (nominal).

Geotextile:

The geotextile is a heavy-duty, non-woven, permeable, polypropylene fabric, available in either green or sand color.

Please feel free to contact us if you do not see what you need, we will help you.

| Item | Wire Dia. | Mesh | Height | Width | Length | Cells |

| (mm) | (mm) | (Meter) | (Meter) | (Meter) | (pcs/unit) | |

| HB61T | 4.0 | 76.2*76.2 | 0.61 | 0.61 | 1.22 | 2 |

| HB61F | 4.0 | 76.2*76.2 | 0.61 | 0.61 | 3.05 | 5 |

| HB61S | 4.0 | 76.2*76.2 | 0.61 | 0.61 | 6.1 | 10 |

| HB100S | 4.0 | 76.2*76.2 | 1.00 | 1.50 | 10 | 6 |

| HB100N | 4.0 | 76.2*76.2 | 1.00 | 0.76 | 9.14 | 9 |

| HB100T | 4.0 | 76.2*76.2 | 1.00 | 1.00 | 10 | 10 |

| HB137N | 4.0 | 76.2*76.2 | 1.37 | 1.06 | 10 | 9 |

| HB137T | 4.0 | 76.2*76.2 | 1.37 | 1.22 | 10 | 9 |

| HB168F | 4.0 | 76.2*76.2 | 1.68 | 0.61 | 3.05 | 5 |

| HB213F | 4.0 | 76.2*76.2 | 2.13 | 1.52 | 7.62 | 5 |

| HB221F | 5.0 | 76.2*76.2 | 2.21 | 2.13 | 8.52 | 4 |

- Q: On the issue of their own screen printing

- Print a colored pattern on a white shirt, I'm now nothing I wanna know what i need ...

- Q: What is the process of the screen printing process?

- The screen has a flat weave, twill weave, semi-woven, all woven. White screen exposure easily lead to diffuse reflection, golden, red, amber absorption of ultraviolet light, can prevent halo

- Q: What are the reasons for the hair making of the screen plate?

- Exposure time is the most important, lack of time, after the version of the mucus to stay in the screen, affecting the printing edge, a long time, it is not easy to open the screen, it will be printed edge defects caused by burr.

- Q: How to get the correct fishing wire

- close the net, with a large bowl in accordance with the way when the net wire to close the net, with the float side of the received good, there are fish directly to the basin.

- Q: Screen printing and other printing methods of the difference

- Ink variety, can print a variety of special effects, three-dimensional sense of strong. The printing method is infinitely changing.

- Q: The difference between screen printing characteristics

- The screen printing can be a large area of printing, the largest format up to 3 m × 4 m, or even greater.

- Q: What is the commonly used mapping software for screen printing?

- screen printing is a stencil printing, it is printed with India, embossing, gravure together known as the four printing methods. The stencil printing includes transcripts, engravings, stencils and screen printing.

- Q: Screen printing and screen printing plate on the photosensitive material What are the requirements

- posters, business cards, binding cover, product signs and printing and dyeing textile and other silk screen pollution process first plate production The use of ink in the developer is the production of ink bucket cleaning is to produce cleaning waste or waste wipe

- Q: Screen printing has several characteristics

- What is screen printing Screen printing is a stencil printing, it is printed with flat, embossed, gravure printed together known as the four printing methods. Stamp printing, including transcript version, engraved version, spray and screen printing.

- Q: Is the screen printing the best way? And other printing methods than it?

- If directly on the irregular printed above certainly use the screen, the other to see his bid, you should and your home printing factory to contact

Send your message to us

Gabion Box in Military/ Hesco Bastion/ Welded Gabion Box

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords