FRP Sheet Making Machine with Good Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 24 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

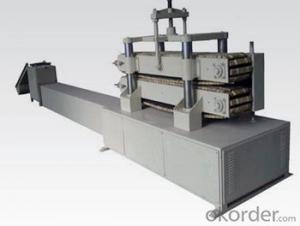

FRP Sheet Making Machine with Good Price

Product Description:

The Sheet Molding Compounds(SMC)-process is one of popular process technology for fibrereinforced

polymers. It is a kind of press-flow-forming technique-to press the semifinished flat SMC -Sheet under

heat and pressure in the mould. The SMC-sheet is built up continuously from short fibre (20 -50 mm) or

endless-fibermats impregnated with a filled resin system.After the “SMC-Sheet” are finished it will be stored for several days so that they can reach the adequate consistency.

Product Features:

1.Apply high precision import forging doctor blade, smaller tolerance.

2.PLC automatic control system, Easy operation, operation people can finish production independently.

3.Special temperature control system. Machine can be heating faster. Accurate temperature control.

4.Roving chopper speed can be synchronous with the production line.

5.For special parts, selection of cables is paid special attention.

Product Parameter:

Name | FRP Sheet Making Machine with Good Price |

Brand | CMAX |

Weight | 5T |

Dimension(L*W*H) | 7m*1.3m*2.4m |

Power | 15KW |

Voltage | 380V 50HZ |

Product Type | FRP Machinery |

Certification | ISO9001:2008 |

Appilication | Sheet |

Raw material | Fiber Reinforced Plastic |

Place of Origin | Beijing, China (Mainland) |

Color | Customized |

Warranty | 1 Year |

Time of Delivery | 30-45 days |

Product Pictures:

FAQ:

1.How can you ensure your quality?

First, welcome to visit us. After your vision in our factory , envionment and work team, you can judge by yourself.

Second, according to your request, we can provide the same sample for you to confirm.

Third, We have inspectional department.

2. Can we visit your factory?

Welcome. We hope you and your team come to our company.

3.Can you provide sample ?

Yes, we can provide sample and it's free. You only charge the freight fee, and we will return the freight fee if you set the order.

- Q: I want to use POM plastic to do mechanical disc cam, processed with sheet metal. (small dosage)Do other plastics have mechanical strength?

- Can be processed, but pay attention to cutting tools to be sharp, cutting force should be small, and fully cooled.The material is of good mechanical strength, and I know nothing in the plastic can match it.

- Q: How much does it cost to run a small waste plastics processing plant?

- Hello, you need to tell me in which city and set up factories in general a small waste plastic particles Factory granulation machine and rolling machine related maintenance tools almost one hundred and twenty thousand or so this is the lowest level for the continuous operation of the workers to four hundred pounds or twenty total count down several flat covering but the mechanical and artificial need not one hundred and eighty thousand factory covers an area of such the words of small plastic granulation plant can take 25

- Q: What are the processes and machines used in the manufacture of plastic products?,

- Processing methods are: injection molding, extrusion, blow molding, blister and so on. Injection molding can be used to produce more complex shapes, such as TV housings. It is the plastic particles in the pre heating tube, and then through the screw under pressure, the melting of raw materials into the mold, cooling molding, the product has been made. Is prepared by continuous extrusion screw drive, which in the feed pipe (commonly known as the barrel) heating plasticization, and then squeeze the stereotypes in the mold, the desired shape, such as plastic buckle, pipes etc.. Blow molding and extrusion are somewhat similar, except that they are placed in compressed air to obtain shapes, such as plastic films, plastic bottles, etc.. Blister is relatively simple, it first made of plastic sheets, baking oven, and then placed in the mold, through the negative pressure to the sheet and mold close to the shape. The price of the equipment varies greatly according to the model and specifications, so it can be checked directly to the manufacturer.

- Q: I found that the plastic bags and food bags used in the county town of my work are from abroad. I would like to open a plastic bag processing plant. What kind of machines do I need?. How much is it (cheaper, smaller per day)?. Where does the raw material go in?. The main market for vegetables; small bags for small food. Who will answer in detail?. Thank you

- Recommended Xiangxi inspection, old plastic easy to do, but have no production, proposed to do environmental protection cloth generation.

- Q: profit is not big, about how much investment, please expert advice, mainly to supply the market and small supermarkets

- I just do this, the raw material is used PE, equipment, there are mainly blowing machine, punching machine, if you want to print, then also the printing press, there are other stirring what ah!

- Q: where there are advanced environment-friendly recycled plastic processing equipment?

- Environmental protection recycling plant, this is a systematic project, the use of granulation machine is usually used granulator, need to be matched with waste water filtration, sedimentation, purification treatment pond, waste gas purification equipment.

- Q: I haven't done it before, and I don't know how to do it Would you please tell me how to do this? How to do it? Good to do

- First you need to recover some of the waste plastics, and then processing the plastic grain, in this process, you will also find a good sales channels, you can find some plastic products factory, plastic grain demand to talk about things and they are. You need to buy some advanced machines for processing plastic particles, so as to ensure the quality of the plastic particles.

- Q: In Shengze where you can find what rags processed into a plastic factory

- You mean it woven rags! Use a plastic granulator.

- Q: Plastics are processed into raw materials. How much raw material and energy do we need to process a kilogram of plastic?

- Is the necessary equipment for extrusion blow molding machine, you must first set up the company, production workshop, production equipment, testing equipment, inspection personnel and production licenses for the government, as the raw material is plastic particles, costs and profits can not be known, see you how to operate.

- Q: One hundredUrgently!!!Find a kind of plastic that can be used for machining. The better the machining performance, the cheaper the better.Used for the principle model, in the past, when the school practice, used a milky white opaque material, feel good, but I do not know what the name.Copy paste party, do not come to a great God level, experienced best. Kneel thanks!Can PVC be used for machining? As long as you can get on the lathe. If there is a better buy channels.To pipe, diameter 20,40, 65mm 1 each. The lengths are 450450335mm.Can PMMA (acrylic) stick be machined? The supervisor told me that nylon rods do not work and that moisture size is not guaranteed.Then suggest I use this... Which is better than PVC? Thank you

- PSU plastic, this plastic can be machined. The factory where I practiced has used detailed parameters. You can check it online

Send your message to us

FRP Sheet Making Machine with Good Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 24 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches