Broward Tape and Packaging Foam Adhesive Tape Double Sided Medical Heat-Resistant

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product details

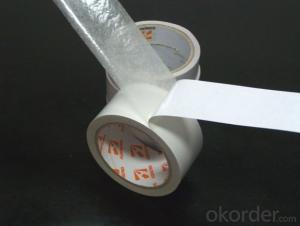

Product category | Color | Expansion ratio | Thickness | Standard Density | Hardness range |

Single side foam tape | White | 40 | 2.50 | 25 | 5-10 |

Common double side foam tape | White | 40 | 2.50 | 25 | 5-10 |

Hanging hook double side foam tape | Yellow | 10 | 1.00 | 100 | 35-45 |

Car double side foam tape | Black | 10 | 1.00 | 100 | 35-45 |

2.Packaging & Delivery

Packaging Details:

90-180 rolls per carton(58*40*30) according to different size

Delivery Detail:

7 to 30 days according to different quantity

3.Company information

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win.

4. product show

- Q: What is the difference between acrylic and hot melt adhesive for packaging tape?

- Packaging tape commonly utilizes two types of adhesives: acrylic and hot melt. These adhesives possess distinct characteristics that set them apart. A significant disparity lies in their bonding strength. Hot melt adhesive boasts exceptional bonding strength, making it ideal for heavy-duty applications. It creates a robust and durable bond that can withstand rigorous handling and varying temperatures. Conversely, acrylic adhesive typically offers a lower level of bonding strength in comparison. While still suitable for most general packaging requirements, it may not be the best choice for heavy or bulky items. Another distinction can be found in the application process. Hot melt adhesive is applied in a molten state and solidifies once cooled. Typically, it is dispensed using a hot melt glue gun or applicator. The quick setting time of hot melt adhesive allows for swift packaging operations, making it popular in high-volume settings. On the other hand, acrylic adhesive is applied in a liquid form and requires some time to cure and establish a strong bond. It can be applied using a hand dispenser or tape gun, and optimal adhesion often necessitates some pressure. Moreover, hot melt adhesive demonstrates excellent adhesion to a wide array of surfaces, including cardboard, plastics, and metals. Its versatility allows for usage with various packaging materials. While acrylic adhesive also adheres well to different surfaces, it may not exhibit the same level of compatibility with certain low-energy surfaces, such as polyethylene or polypropylene. Furthermore, temperature resistance is an essential factor to consider. Hot melt adhesive performs admirably in both high and low temperatures, maintaining its bonding strength. It can endure freezing temperatures and heat without compromising its adhesive properties. Acrylic adhesive, while generally offering good temperature resistance, may not be as effective in extreme conditions, particularly at very high or low temperatures. In conclusion, the primary disparities between acrylic and hot melt adhesives for packaging tape lie in bonding strength, the application process, surface compatibility, and temperature resistance. While hot melt adhesive provides superior bonding strength, rapid setting time, and excellent temperature resistance, acrylic adhesive offers versatility, ease of application, and good adhesion to most surfaces. The choice between the two depends on specific packaging needs, materials used, and environmental conditions.

- Q: Can packaging tape be used for mailing packages?

- Yes, packaging tape can be used for mailing packages. It is commonly used to secure and seal packages, ensuring that they remain intact during transit.

- Q: Can packaging tape be used for other purposes besides packaging?

- Yes, packaging tape can be used for other purposes besides packaging. It can be used for sealing envelopes, securing loose items, repairing torn paper or books, creating temporary labels, organizing cables, and many other miscellaneous tasks.

- Q: Can packaging tape be used for bundling items together?

- Yes, packaging tape can definitely be used for bundling items together. It is commonly used to secure and hold multiple items together, especially when shipping or moving. Packaging tape is designed to be strong and reliable, providing a secure hold that keeps items bundled tightly. It is often used to bundle boxes, packages, or other items that need to be kept together during transportation or storage.

- Q: Does packaging tape come in different materials for specific applications?

- Yes, packaging tape does come in different materials for specific applications. These materials include polypropylene, PVC, paper, and filament tape. Each material has unique properties that make it suitable for various purposes such as sealing lightweight packages, securing heavy boxes, or providing extra strength and tear resistance.

- Q: Is packaging tape safe to use on painted furniture?

- Yes, packaging tape is generally safe to use on painted furniture. It is designed to adhere to various surfaces, including painted surfaces, without causing damage or leaving residue when properly applied and removed. However, it is always recommended to test a small, inconspicuous area first to ensure compatibility and to handle the tape with care to avoid any potential paint or finish peeling.

- Q: What is the purpose of packaging tape?

- The purpose of packaging tape is to securely seal and reinforce packages, boxes, or containers during storage, transportation, or shipping. It is designed to provide a strong, long-lasting bond that keeps the contents of the package intact and protected. Packaging tape also serves as a visual indicator of tampering, as any unauthorized opening or tampering can be easily identified. Additionally, it helps to prevent dust, moisture, and other external elements from entering the package, ensuring the integrity and quality of the enclosed items. Overall, the purpose of packaging tape is to provide a reliable and efficient solution for sealing and protecting packages, making it an essential tool for businesses, individuals, and organizations involved in shipping and logistics.

- Q: What are the considerations for using packaging tape on corrugated cardboard boxes?

- There are several factors to consider when using packaging tape on corrugated cardboard boxes. Firstly, it is crucial to choose the appropriate type of tape for the job. Acrylic, hot melt, and natural rubber adhesive tape are all available options, each with its own strengths and weaknesses. Therefore, it is vital to select a tape that offers the necessary strength and durability to secure the cardboard boxes effectively. Moreover, the width and thickness of the tape should be taken into account. The tape's width should be sufficient to cover the box's seams and edges, ensuring a secure seal. Similarly, the tape's thickness should be suitable for the weight and contents of the box. Heavier items may require thicker tape to provide proper support and prevent damage during transportation. Another consideration is the application method. It is crucial to apply the packaging tape evenly and tightly to the cardboard boxes to prevent them from becoming loose or opening during transport. Using a tape dispenser or applicator can assist in achieving a consistent application. Additionally, the conditions under which the cardboard boxes will be handled and transported should be considered. If the boxes will be exposed to extreme temperatures, humidity, or rough handling, it might be necessary to use stronger or specialized packaging tape that can withstand these conditions. This will ensure that the tape remains intact and provides the necessary protection for the box's contents. Lastly, the removal of the packaging tape should be taken into account. If the boxes need to be opened and resealed multiple times, it might be beneficial to use a tape that offers easy and clean removal without leaving residue or damaging the cardboard surface. This will help maintain the box's integrity and make it easier to reuse or recycle the corrugated cardboard. In conclusion, when using packaging tape on corrugated cardboard boxes, it is important to consider factors such as the type, width, and thickness of the tape, as well as the application method. The conditions under which the boxes will be handled should also be taken into account, and the removal of the tape should be considered if the boxes require multiple openings. By considering these factors, one can ensure that the packaging tape provides a secure and reliable seal for the corrugated cardboard boxes.

- Q: Are there any safety precautions to consider when using packaging tape?

- Yes, there are several safety precautions to consider when using packaging tape. Firstly, it is important to ensure that you are using the tape in a well-ventilated area, as some adhesive fumes can be harmful if inhaled excessively. Additionally, it is crucial to handle the tape dispenser with care to avoid any injuries. Make sure to use proper hand placement and avoid placing your fingers too close to the cutting blade to prevent accidental cuts. Furthermore, when using packaging tape, it is advisable to wear appropriate protective gear, such as gloves, to protect your hands from any potential adhesive residue or cuts. Lastly, it is essential to store the tape in a safe and secure place, away from children or pets, to prevent any accidental ingestion or misuse. By following these safety precautions, you can ensure a safe and efficient use of packaging tape.

- Q: How do I cut packaging tape without scissors?

- In the absence of scissors, there are various alternative techniques that can be employed to cut packaging tape. One possibility entails utilizing a sharp knife or a utility knife, while ensuring utmost care is taken and fingers are kept away from the blade. Another approach involves employing a box cutter or a pocket knife, once again taking precautions to handle it safely. In case cutting tools are not accessible, one can attempt tearing the tape by firmly gripping it with both hands and swiftly pulling it apart. Nevertheless, it should be noted that this method might not consistently yield a clean cut. Additionally, resorting to using one's teeth to tear the tape is an option, although it is not advisable due to the potential risk of tooth damage or injury. It is crucial to always prioritize safety and exercise caution when employing any sharp objects for the purpose of cutting packaging tape.

Send your message to us

Broward Tape and Packaging Foam Adhesive Tape Double Sided Medical Heat-Resistant

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords