FM Approved Rubber Plastic with Aluminum Foil Facing

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

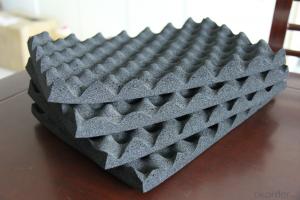

CMAX Rubber Plastic Product advantages:

Fire-blocking, Low Conductivity factor, Good pliability, Closed pore foaming, Good damp-proof property, Vibration resistance, Easy to install and beautiful appearance

| Item | Unit | Specification | Standard | |

| Density | Kg/m³ | ≤95 | GB/T6343 | |

| Oxygen index | % | ≥32 | GB/T2406 | |

| Flammability | SDR | —— | ≤75 | GB/T8627 |

| Conductivity factor | W/(m.k) | |||

| Average temperature | ||||

| -20°C | ≤0.031 | GB/T10294 | ||

| 0°C | ≤0.034 | |||

| 40°C | ≤0.036 | |||

| Watervapor permeability | Coefficient | g/(m.s.pa) | ≤2.8*10-11 | GB/T17146-1997 |

| Factor | —— | ≥7.0*10³ | ||

| Water absorption ratio in vacuum | % | ≤10 | GB/T17794-2008 | |

| Dimension stability | % | ≤10 | GB/T8811 | |

| 105±3°C,7d | ||||

| Crack resistance | N/cm | ≥2.5 | GB/T10808 | |

| Compression resilience ratio | % | ≥70 | GB/T6669-2001 | |

| Compression time 72h | ||||

| Anti-ozone | —— | Not cracking | GB/T7762 | |

| Ozone pressure 202mpa | ||||

| 200h | ||||

| Aging resistance | —— | Slightly crumpling, | GB/T16259 | |

| 150h | no cracks, | |||

| Temperature | °C | -40°C——110°C | GB/T17794 | |

- Q: This question asks for a method to determine the thickness of an aluminum foil sheet.

- <p>To measure the thickness of an aluminum foil sheet, you can use a digital caliper or a micrometer. Place the foil between the jaws of the caliper and take the measurement. If you don't have these tools, you can use the 'multiple fold' method: fold the foil in half repeatedly and measure the total thickness after several folds, then divide by the number of layers to estimate the single layer thickness. For a more precise measurement, especially for thinner foils, consider using a thickness gauge designed for measuring thin materials.</p>

- Q: Explain the distinct features of aluminum foil facing compared to other food covers.

- <p>Aluminum foil facing is a type of food cover that is made from thin sheets of aluminum, known for its high heat conductivity, moisture resistance, and ability to seal in freshness. It's often used for cooking, baking, and preserving food. Other types of food covers include plastic wraps, which are more flexible and cling to food surfaces but may not be as effective at heat conduction or preserving freshness; glass or ceramic lids, which are reusable and provide an airtight seal, but are heavier and not as convenient for single-use applications; and silicone covers, which are heat resistant and can be reused, but may not seal as tightly as aluminum foil.</p>

- Q: What is the function or use of aluminum foil facing in construction or insulation?

- <p>Aluminum foil facing is used primarily for thermal insulation in construction and HVAC systems. It reflects radiant heat, reducing heat transfer and improving energy efficiency. It also serves as a vapor barrier, preventing moisture from passing through insulation, which can reduce its effectiveness. Additionally, aluminum foil facing can provide a clean, finished appearance and protect the insulation material from damage and contamination.</p>

- Q: Is it safe to use recycled aluminum foil for cooking or baking purposes?

- <p>Recycled aluminum foil facing is not recommended for cooking or baking. While aluminum foil itself is safe for cooking and can be used to cover dishes or line baking sheets, recycled foil may have impurities or contaminants from previous uses. It may also be thinner and less durable, leading to potential tearing or puncturing, which can result in food contamination. For safety and food quality, it's best to use new, high-quality aluminum foil for cooking and baking.</p>

- Q: Describe the process of aluminum foil facing in a few sentences.

- <p>Aluminum foil facing is a process used to laminate aluminum foil to a substrate, typically for decorative or functional purposes. The process begins with the preparation of the substrate, ensuring it is clean and free of contaminants. Then, a layer of adhesive is applied to the substrate. The aluminum foil is then placed onto the adhesive-covered substrate and pressure is applied to ensure proper adhesion. The laminated product is then cured, which can involve heat or UV light to set the adhesive. Finally, the product is trimmed and inspected for quality before being packaged and shipped. This process is used in various industries, including construction, automotive, and consumer goods.</p>

- Q: The user is asking if it's possible to use aluminum foil with a reflective side facing out to cook a roast chicken.

- <p>Yes, you can use aluminum foil facing to make a roast chicken. The reflective side of the aluminum foil can help to retain heat and cook the chicken more evenly. However, it's important to note that the foil should not be in direct contact with the heat source for an extended period as it may cause the foil to melt or create a fire hazard. Make sure to monitor the cooking process and adjust the foil placement as needed to prevent any safety issues.</p>

- Q: Is it possible to use aluminum foil with a non-stick coating as a substitute for non-stick baking or grilling pans?

- <p>Yes, aluminum foil facing can be used as a non-stick surface for baking pans or grilling pans. It provides a smooth, non-stick surface that prevents food from sticking and makes cleanup easier. However, it's important to ensure that the foil is heavy-duty and not too thin to avoid tearing during use. Additionally, while it can be a temporary solution, it's not as durable as a true non-stick surface and may require frequent replacement.</p>

- Q: What are the primary applications or purposes of aluminum foil facing in various industries or everyday life?

- <p>Aluminum foil facing is primarily used for its heat reflective properties, making it ideal for insulation in construction and roofing. It also serves as a moisture barrier and vapor barrier in walls and ceilings, helping to prevent mold and mildew. In the HVAC industry, it's used for duct insulation, enhancing energy efficiency. Additionally, it's utilized in packaging for food and pharmaceuticals to protect contents from light, air, and moisture, thus preserving freshness and quality.</p>

- Q: Is it safe to use aluminum foil facing on lunch boxes for making sandwiches or wraps?

- <p>Yes, you can use aluminum foil facing to make sandwiches or wraps for lunch boxes. Aluminum foil is a common material used for food packaging due to its ability to keep food fresh and protected. It is non-toxic and does not react with most foods, making it safe for use in lunch boxes. However, it's important to ensure that the foil does not tear or come into direct contact with acidic foods, as this could potentially lead to the leaching of aluminum. Always handle food with clean hands or utensils to maintain hygiene.</p>

- Q: This question asks for the method to wrap a hot pan using aluminum foil, with specific instructions on how the foil should face.

- <p>To wrap a hot pan with aluminum foil, first ensure the pan is stable and on a heat-resistant surface. Take a large piece of aluminum foil, about twice the size of the pan. Hold one corner of the foil and drape it over the pan, allowing the shiny side to face the pan. Gently press the foil against the pan, working your way around the edges to cover the entire surface. Ensure the foil is snug but not too tight to avoid tearing. The shiny side facing the pan will help reflect heat and protect the pan's surface. Be cautious while handling the hot pan and aluminum foil to avoid burns.</p>

Send your message to us

FM Approved Rubber Plastic with Aluminum Foil Facing

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords