Flat Aluminum Strips in Roll Shutter Aluminum Coil with Different Specifications

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

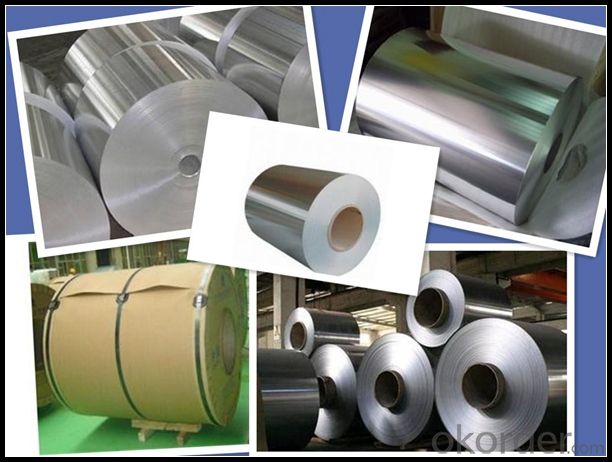

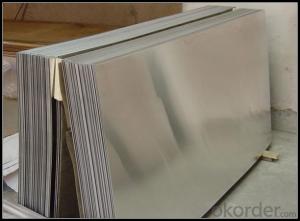

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: This question asks for a comparison of the pros and cons associated with the use of aluminum strips in roofing systems.

- <p>Aluminum strips in roofing offer several advantages such as durability, resistance to corrosion and rust, lightweight nature, and low maintenance requirements. They are also energy-efficient, reflecting heat and reducing cooling costs. Additionally, aluminum strips can be easily recycled, contributing to environmental sustainability. However, there are downsides, including higher initial costs compared to other roofing materials and potential for denting if not properly installed or maintained. Aluminum can also be noisy during rain, and may require more frequent replacement due to its lighter gauge compared to some other materials.</p>

- Q: What types of aluminum strips are known for their durability and longevity?

- <p>Yes, there are several types of aluminum strips known for their durability and longevity. These include 3003-H14, 5052-H32, and 6061-T6 aluminum alloys. 3003-H14 is known for its excellent corrosion resistance and formability, making it ideal for applications requiring high durability. 5052-H32 offers good strength, corrosion resistance, and weldability, suitable for marine and structural applications. 6061-T6 is valued for its high strength-to-weight ratio and is commonly used in aerospace and automotive industries where long-lasting performance is crucial. Proper surface treatments and coatings can further enhance the durability and longevity of aluminum strips.</p>

- Q: This question asks about the uses of aluminum strips within the construction industry.

- <p>Aluminum strips are widely used in construction due to their strength, durability, and resistance to corrosion. They are commonly used in the manufacturing of window and door frames, as they are lightweight and provide excellent thermal insulation. Aluminum strips are also used in the construction of scaffolding, roofing, and cladding systems due to their high strength-to-weight ratio and ease of installation. Additionally, they are employed in electrical wiring as conduits and in the framing of structural components due to their non-magnetic and non-sparking properties, making them safe for use around electrical equipment.</p>

- Q: Classification of aluminium strips of aluminium strips

- Aluminum strip is a strip of aluminum ingot obtained by press rolling, according to the use of different grades, specifications, status. The aluminum belt has many uses, such as: aluminum plastic composite pipe, cable, fiber optic cable, transformer, heater, shutter and so on. The processing technology of aluminum strip is the aluminum deep processing product formed by the slitting and slitting of aluminum rolls. It is an important raw material in industry. According to the aluminum alloy containing aluminum and aluminum with different origin, the same is also divided into 8 series. However, the commonly used series for the 100030005000 and 8000 Series, depending on the annealing state of the aluminum strip, the aluminum strip can be divided into fully soft (o), semi hard (H24) hard (h18). At present, the most commonly used should belong to the whole soft series, because the O state is easier to stretch and bend. The main processing equipment of aluminum strip is a strip mill, which can be divided into required length and width according to need. Of course, the processing equipment is universal, copper coil can also be processed, processed products known as copper strip. At present, the international raw materials for electronic products are no longer purely dependent on copper strip. As the conductivity of aluminum is only lower than copper, the aluminum strip instead of copper strip is becoming a popular trend in the world. The classification of aluminium tapes includes pure aluminium belt, transformer, aluminium belt, super hard aluminium belt, full soft aluminium belt, semi hard aluminium belt and antirust aluminium belt.

- Q: This question asks for advice on choosing high-quality aluminum strip roofing materials.

- <p>When selecting quality aluminum strip roofing materials, consider the following tips: 1. Gauge Thickness: Opt for a thicker gauge for increased durability and resistance to weathering. 2. Coating: Look for materials with a protective coating, such as Kynar 500 or Hylar 5000, which offer superior resistance to fading and chalking. 3. Color Options: Choose materials with a wide range of color options to match your home's aesthetic. 4. Energy Efficiency: Select materials with high solar reflectance to reduce cooling costs. 5. Manufacturer Reputation: Research the reputation of the manufacturer for quality and reliability. 6. Certifications: Ensure the materials meet industry standards and certifications, such as the American Society for Testing and Materials (ASTM). 7. Warranty: A good warranty is a sign of confidence in the product's quality and longevity. 8. Installation: Consider the ease of installation and whether the material requires specialized tools or techniques.</p>

- Q: Does aluminum maintain its properties and resist damage from fire?

- <p>Aluminum strips are relatively fire-resistant, but not completely immune to damage. Aluminum has a high melting point of approximately 660掳C (1220掳F), which means it can withstand high temperatures without melting. However, it can still oxidize and corrode at elevated temperatures, leading to a loss of structural integrity over time. While it may not catch fire, it can still be affected by prolonged exposure to fire, and its performance can degrade depending on the specific conditions and the protective measures in place.</p>

- Q: Is it possible to construct awnings or canopies using aluminum strips?

- <p>Yes, aluminum strips can be used to make awnings or canopies. They are lightweight, durable, and resistant to corrosion, making them suitable for outdoor applications. Aluminum's strength and flexibility allow it to be bent and shaped easily, which is ideal for creating the curved or angled structures often seen in awnings and canopies. However, it's important to ensure that the aluminum is of sufficient gauge to support the weight and withstand environmental stresses. Additionally, proper sealing and treatment are necessary to prevent water damage and maintain the longevity of the structure.</p>

- Q: Explain the relationship between aluminum strips and aluminum foil, including their similarities and differences.

- <p>Aluminum strips and aluminum foil are both made from the same material, aluminum, but they differ in their form and thickness. Aluminum strips are typically thin, flat pieces of aluminum that are longer and narrower compared to aluminum foil. They are often used in industrial applications, such as in the manufacturing of electrical components or as a conductive material in various devices. Aluminum foil, on the other hand, is much thinner and is commonly used in cooking, food storage, and packaging due to its high barrier properties against air and moisture. While aluminum strips may be thicker and more rigid, aluminum foil is lightweight and flexible, making it suitable for a wide range of consumer and household uses.</p>

- Q: Explain the distinction between aluminum foil and aluminum strips, including their typical uses and characteristics.

- <p>Aluminum foil and aluminum strips are both made from aluminum but differ in thickness and application. Aluminum foil is very thin and flexible, typically used for food packaging, cooking, and insulation due to its light weight and barrier properties. It is often found in kitchens for wrapping food or lining baking sheets. Aluminum strips, on the other hand, are thicker and more rigid, used for structural purposes, such as in construction, automotive parts, or electrical components. They are also used in manufacturing for creating more durable and robust products. The thickness and flexibility of aluminum strips make them suitable for applications requiring strength and shape retention.</p>

- Q: Can aluminum strips be utilized as materials for car body panels?

- <p>Yes, aluminum strips can be used for car body panels. Aluminum is known for its lightweight, high strength, and corrosion resistance, making it an ideal material for automotive applications. It offers better fuel efficiency due to reduced weight and improved safety due to its strength. Additionally, aluminum's recyclability makes it an environmentally friendly choice. However, it's important to note that aluminum requires different manufacturing techniques compared to traditional steel, and it may be more expensive.</p>

Send your message to us

Flat Aluminum Strips in Roll Shutter Aluminum Coil with Different Specifications

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords