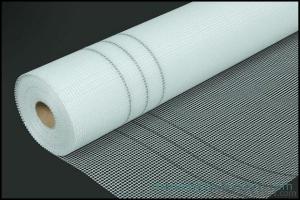

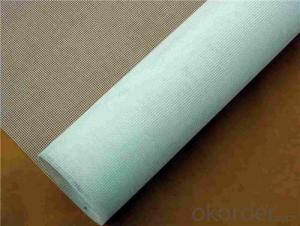

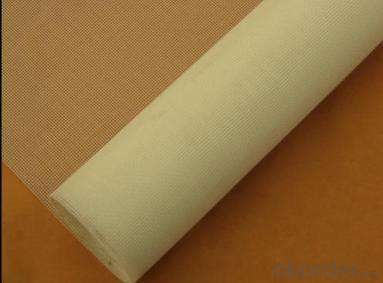

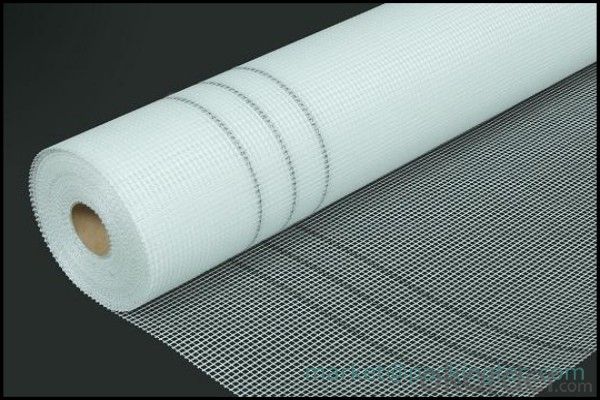

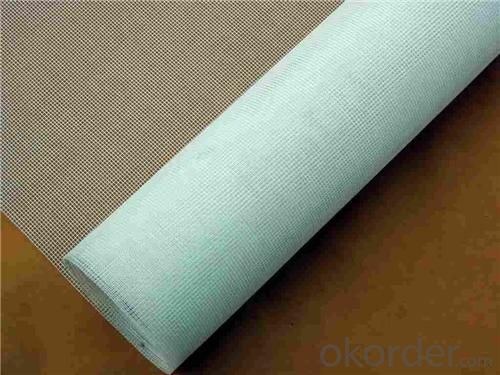

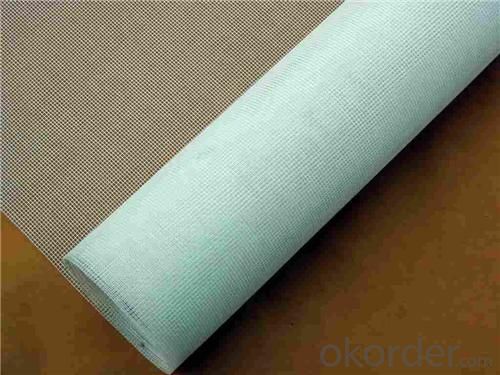

Fiberglass Insect Screen Mesh with 14*14 in Green

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

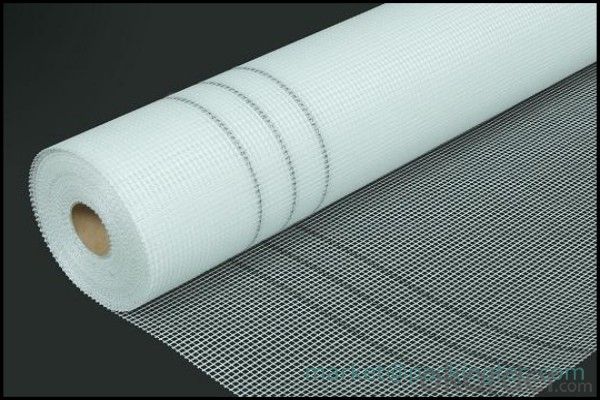

Product Description of Insect Screen Mesh:

Specifications of Insect Screen Mesh

Clear to see through

Block insect and mosquito effectivly

Easy to wash

Major character of Insect Screen Mesh

1 . Environmental protection:

Non harmful to the atmosphere of chlorine fluoride, in line with ISO14001 international environmental protection certification, so does not produce any harmful pollution.

2 . Long service life:

Excellent weather resistance, anti-aging, anti-cold, anti-heat, anti-dry, anti-moisture, fire-retardant, anti-static, light transmission is good, is not channeling wire, non-deformation, anti-ultraviolet, tensile strength, the use of long life and so on.

Production Process of Insect Screen Mesh

The main material is high-quality textile-type polyester yarn as. We also produce fiberglass year coated with PVC resin,single-wire technology,through textiles,stereotypes and testing process.

Usage: pastures,orchards,gardens,transport,industry,health,civil construction as so on

Notice on Insect Screen Mesh

1.Mesh opening:18×16mesh18×14mesh 16×16mesh16×14mesh etc

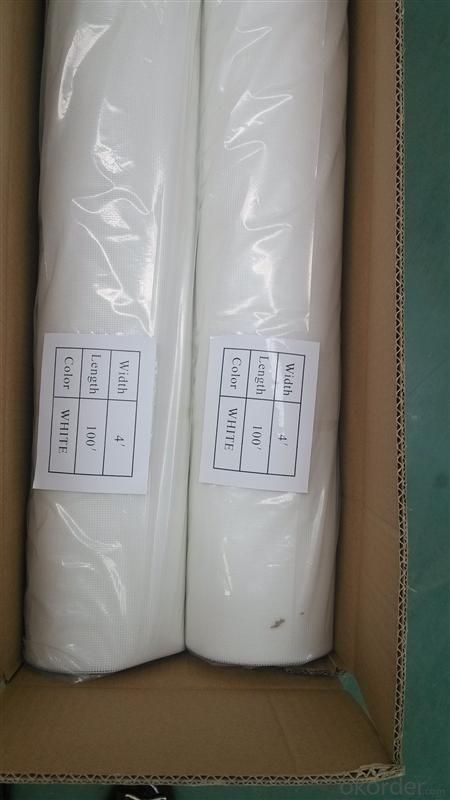

2.Width: 61cm71cm80cm 100cm 110cm 122cm 142cm 152cm 162cm 183-280cm.

3. Mainly color: black, white, green, yellow, gray etc.

4.The specifications color and mesh can according to the customer's requirements

Technical Specification

Standard Sizes:20x20mesh,20x18 mesh,18x18 mesh,18x16 mesh,18x14 mesh,16x16 mesh,16x14 mesh,14x14 mesh.

Color Available:Gray,black,white, green,yellow,gray white.Other colors customized.

Roll Width: 5''to 108''.Roll Length:100'-600'

Yarn Diameter: 0.28mm,0.33mm

- Q: Industrial metal woven square hole network where there is a download, urgent

- Please provide email address

- Q: There is no relevant standards can be customized pipe diameter is 42

- Imported hydraulic tubing and transition joints, Teflon tube, stainless steel pipe, seamless steel pipe, copper pipe fittings, steel pipe fittings, pneumatic fittings, hydraulic parts etc..

- Q: Excuse me, how to choose the soft copper connections copper braided wire connection or connection?

- Because the braided line impedance is relatively large, the bearing capacity is relatively weak, so try to choose a non power connection, and cost considerations, most have chosen instead of copper braided wire, only some specific environment and work requirements will be used in weaving line

- Q: Ore with wire mesh weaving what good

- Make your screen sell in the local shop can. I'm selling this.

- Q: The copper brush wire and copper braided wire which is good

- This statement did not say what good ah, you need to see what is in place.

- Q: Wire mesh is steel plate wire or mine?

- You can find out where to sell mine welding network on the line

- Q: Glue? What kind of glueWelded? How can weave mesh size of 0.12mm welding!!

- Glue does not work, you can use oxygen welding, or can be set on a nail

- Q: Copper braid and copper foil soft joining different soft connection?

- The limitations of the assembly environment, while the copper braid soft connection, which is composed of a round copper wire by a monolayer or multilayer woven, can 360 degrees rotate back and forth, in the assembly point above is not subject to any restrictions on the copper braid in a certain environment than the copper foil soft joining the use of more convenient soft connection.

- Q: Where do you have a live video?

- First of all, raw materials, polyester, polypropylene, etc., which are commonly used

- Q: How to weave badminton net?

- 1 first found a piece of rope, to meet the requirements of the net length.2 divide into equal distances on a rope, tie another rope at the nodes.3 do the best of the above methods.4 complete the remaining two sides.

Send your message to us

Fiberglass Insect Screen Mesh with 14*14 in Green

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords