Geocells Ofisis Nomeri Fiberglass Geogrid with Low Elongation Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

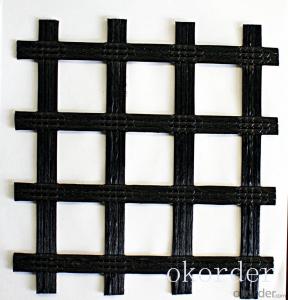

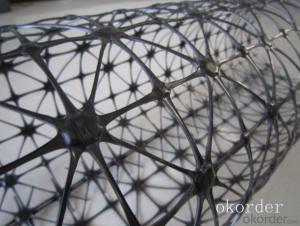

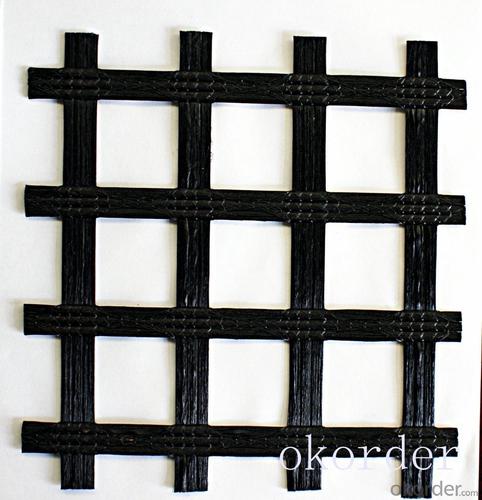

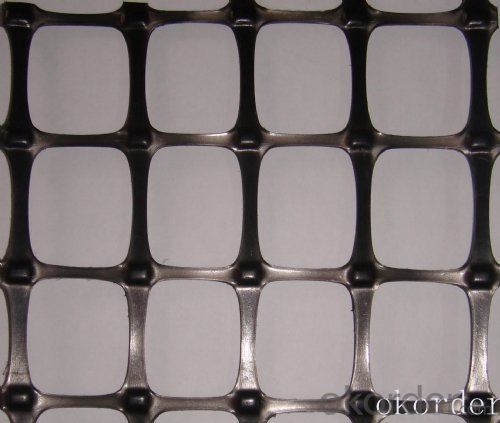

Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is composed of fiberglass filaments that are coated with an inorganic sizing agent

Temperature Resistance (Centigrade): -100~290

Surface Processing: Modified asphalt or Polymer and self adhesive

Packing: With PE bagsType:

Geogrids

Material:

Fiberglass

Coating:

asphalt

feature:

High flexibility and large range

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

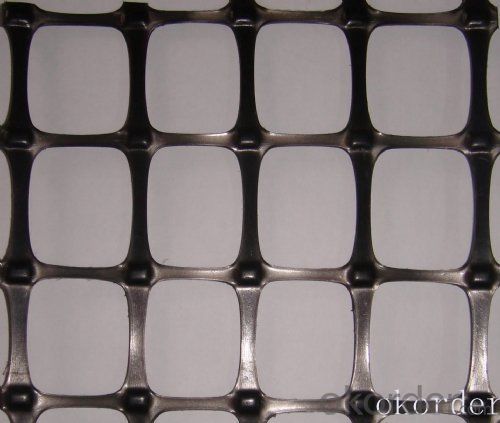

A: Yes, please check the pictures:

- Q: What are the typical applications of geogrids in geotechnical engineering?

- Geogrids are commonly used in geotechnical engineering for various applications such as soil reinforcement, slope stabilization, retaining wall construction, and pavement reinforcement.

- Q: What are the criteria for the use of plastic geogrid

- Each grid has a variety of specifications, the specific reference to the national standard requirements, but the specifications are not necessarily the same as the national standard.

- Q: What are the specifications for geogrid installation?

- The specifications for geogrid installation typically include factors such as the type and strength of the geogrid material, the required overlap or seam allowance, the recommended depth of installation, the recommended slope angle for placement, and any specific site preparation or soil compaction requirements. Other factors to consider may include the desired load-bearing capacity, the expected lifespan of the geogrid, and any additional reinforcement or anchoring methods necessary. It is important to consult the manufacturer's guidelines and any relevant engineering or construction standards for specific specifications and recommendations.

- Q: The difference between two way steel plastic grille and one way steel plastic grille

- There difference

- Q: How to apply the fixed scale of Geogrid

- Can contact.

- Q: What is the typical width of a geogrid roll?

- The typical width of a geogrid roll is usually between 4 to 16 feet.

- Q: Can geogrids be used in retaining walls for waterfront parks?

- Yes, geogrids can be used in retaining walls for waterfront parks. Geogrids are commonly used in retaining wall construction as they provide reinforcement and stability to the soil. In the case of waterfront parks, where the retaining walls are exposed to water and potential erosion, geogrids can help prevent soil movement, maintain the integrity of the wall, and enhance its overall durability.

- Q: Can geogrids be used in reinforcement of pavement overlays?

- Yes, geogrids can be used in the reinforcement of pavement overlays. Geogrids are commonly used to improve the structural integrity and durability of pavement overlays by distributing load, reducing cracking, and enhancing overall performance.

- Q: Are geogrids suitable for reinforcement of mechanically stabilized earth retaining walls?

- Yes, geogrids are suitable for the reinforcement of mechanically stabilized earth retaining walls. Geogrids are specifically designed to provide strength and stability to soil structures, and they effectively distribute and transfer loads within the soil mass. By adding geogrids to a mechanically stabilized earth retaining wall, the overall structural integrity and resistance to lateral forces can be significantly enhanced, making them a reliable and effective solution for reinforcement.

- Q: How do geogrids help in reducing the need for excavation and replacement of poor soils?

- Geogrids help in reducing the need for excavation and replacement of poor soils by providing reinforcement and stabilization to the soil, improving its load-bearing capacity. This prevents excessive settlement and movement of the soil, reducing the need for costly excavation and replacement.

Send your message to us

Geocells Ofisis Nomeri Fiberglass Geogrid with Low Elongation Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords