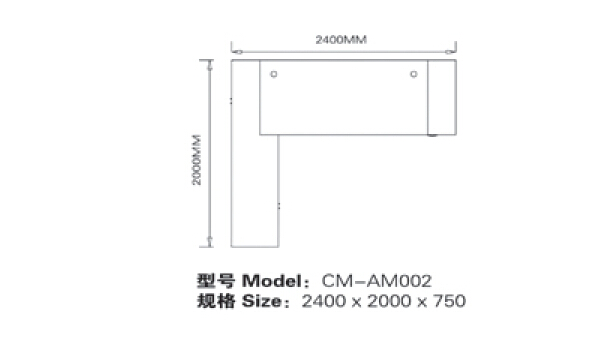

ExecutiveTable Desk Hight Quality Wood Melamine/Glass Office AM002

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 60 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| Type: | Office Furniture | Specific Use: | Office Table | Wood Style: | Metal,MDF,Melamine |

| Certification | ISO9001 Quality & Enviroment | Size | 2800*2800*1050 | Advantages | Attractive Design ,Competitive Price |

| Assembling Guide | Available | customization: | Yes | Specific Uses | Office Desk ,Executive Desk |

| MOQ | 5 sets | Payment Term | T/T,L/C | Delivery Time | 15-20 days |

We specialized in office desk and office seating .Our factory has been engaged in office furniture for more than 10 years. Our factory is well-known in the high quality and competitive price of our products. Therefore, we completed in specifications and win warm praise from customers. In addition, the design of our products is deft, modern and beautiful. There are many types and colors for your selection. Our goods are easy and simple to handle and durable in use.

Welcome any questions!

- Q: Can the bamboo plywood used for building be made at home?

- Bamboo plywood is made of bamboo material as the main structure and filling material!

- Q: The difference between laminated lumber and plywood

- The biggest difference between the two is the formation of a single plate of the embryo, hot pressing and late processing. From the production point of view, LVL plate in the production and processing procedures to be more complex, plywood is relatively simple.

- Q: How do you make the plywood process?

- Single plate - Section - log truncation wooden centering and rotary cutting veneer drying - processing - glue - cooling - Hot - embryo group and truncated - sanding test grading

- Q: What are the specifications of plywood?

- The classification of many kinds of plywood, plywood by species can be divided into softwood and hardwood plywood plywood; use can be divided into ordinary plywood, plywood, cement formwork structure plywood, fireproof plywood and special plywood etc..

- Q: How are the plywood made?

- Plywood usually refers to three plywood or multilayer board, that is, with the same thickness of two or more layers of wood veneer and glue high temperature suppression. Usually, the odd layer single plate is used, and the fiber direction of the adjacent layer single plate is perpendicular to each other.

- Q: What's the market price of bamboo plywood?

- Bamboo plywood is made of bamboo material as the main structure and filling material! Because of the high hardness, bending resistance and compressive resistance of bamboo plywood, steel formwork has been replaced in many use areas! Because bamboo is easy to cultivate, quick forest trees, three to five years will be cut down, can replace wood, therefore, the State Forestry Department policy supports the development of wood-based panels with bamboo as the main materials, has replaced the use of wood plates in a lot of places! What specifications are required for different thicknesses?

- Q: What kind of wood is plywood made of?

- Poplar, poplar rotary peeling, a thin skin slowly came out, so many to peel the skin work shop in bed, laying a layer of wiping a layer of glue, thickness of the machine finally enough pressure, drying, cutting and forming. The plywood is leaving the factory.

- Q: The difference between laminates and plywood

- The plywood is logs into veneer or by wood sliced veneer, with adhesive glued into three or more layers of sheet material, usually with odd veneer, and the fiber direction of adjacent plates perpendicular to each other and gluing.

- Q: What is bamboo plywood?

- Bamboo plywood is made of bamboo material as the main structure and filling material! The main uses are: building mould, grouting, car box, box and box bottom board, large mechanical outer packing board, and various places where the board is needed! Because of the high hardness, bending resistance and compressive resistance of bamboo plywood, steel formwork has been replaced in many use areas! Because bamboo is easy to cultivate, quick forest trees, three to five years can cut the row, can replace wood, therefore, the State Forestry Department policy supports the development of wood-based panels with bamboo as the main materials, has replaced the use of wood plates in a lot of places!

- Q: When the newly bought house is decorated, it is found that there is a crack in the roof line and rubber sheet. What shall I do?

- If the city according to the standard design and construction acceptance or delivery of rural housing has been used for many years, the foundation changes (such as landslides, earthquakes and other causes of empty depression), can be a preliminary judge for the process of cracks and damage, can find out the reasons and the corresponding control schedule.

Send your message to us

ExecutiveTable Desk Hight Quality Wood Melamine/Glass Office AM002

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 60 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords