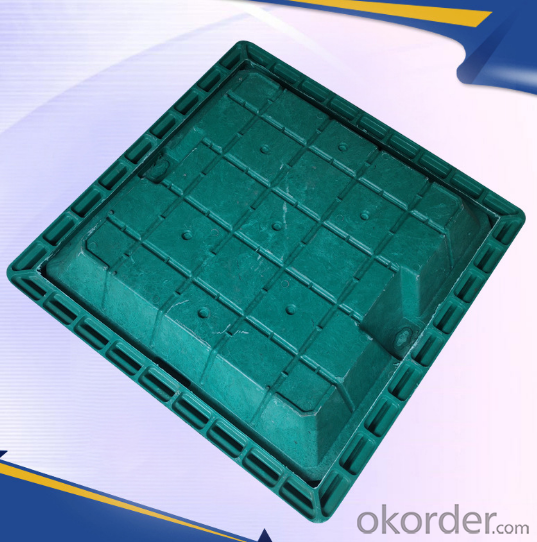

EN 214 ductile iron manhole cover with high quality in Hebei Province

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1) production standard: EN124 from A15 to F900

2) Material: grey iron, ductile iron

3) Type:round type and Square type,triangle

4) Superior quality and anti-corruption

5) we can produce as per customers'drawings

6)ISO9001:2008

7) Design:We can provide OEM services

8) Expressway, sidewalk, park, garden, municipal pipeline, telecommunication, water and electrical power projects all will be avialable.

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Unit Weight (kg/set) |

| D110 | D400 | 1000*1000 | 1100*1100 | 202 |

| D100 | D400 | 900*900 | 1000*1000 | 175 |

Advantages

Competitive prices, bending and impact strength, anti-rust, waterproof, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than other companies.

Higher quality /higher tensile

Higher security /long life

Possibilities of new locking systems

Packaging & Shipping

Packaging: Details Pallet with bubble films, Cartons or with pallets,

Delivery Detail: 8 days if your order is 20"container, we are prepared to ship your gooda as soon as possiable.

FAQ

1. How about your price?

A: As one of famous manufacturers of Ductile iron products inChina, Our prices are very favorable and competitive. The customers from all-over the world.

2. What is your minimum order requirement?

We will indicate the MOQ for each item in the quotation sheet. we accept the sample and trial order. If the quantity of single item can't reach the MOQ, the price should be sample price.

3.How long can you make your quotation:

Within 3 workdays after received your detailed product information

5.Do you provide OEM Service?

Yes, we provide OEM Service.

- Q: How to improve the surface roughness of casting parts?

- One is to improve the accuracy of the model; the two is to improve the molding sand mesh. How much is the other relationship?.

- Q: Why does the surface of stainless steel casting mirror mirror ripple?

- Because the grinding machine is layer by layer. And the material inside the casting is not completely uniform.

- Q: our factory now produces steel castings in the use of polishing directly after spraying processing, but the powder sprayed 15But the spray powder touched off what is the reason we are not very strict requirements not only need to peel off bubbles can also, because our products are steel castings so we use steam hole sludge put on. Do not know if this spray treatment has no effect to thank friends with us!

- The pre treatment temperature and the quality of plastic powder are likely to be problems

- Q: Explain the heat treatment effect of casting parts, forging parts and welding parts

- 2 improve the crystal structure, enhance the formation and stability of spherical carbon crystal;Forgings are generally stress bearing members, and most of them are made of high strength medium carbon steel (alloy), which is formed by forging and fine crystalline. After the shell is annealed or quenched and tempered, the mechanical properties of the shell are more superior, and it has better strength and better elasticity;Welding materials.

- Q: Why do cheap cars like stamping parts instead of casting parts?

- Separation process is also called blanking, the purpose is to make the stamping parts along a certain contour line from the sheet metal separation, at the same time guarantee the quality requirements of the separation section. Stamping is a highly efficient production methods, the use of compound die, especially the multi station progressive die stamping process can be completed in a multi machine, realized by belt uncoiling, leveling, punching, forming and finishing automatic production. High production efficiency, good working conditions, low production costs, can produce hundreds of parts per minute. The purpose of forming processes is to allow the sheet to undergo plastic deformation without breaking the billet and to make the desired shape and size. In actual production, a variety of processes are often applied to a workpiece. Blanking, bending, shearing, drawing, bulging, spinning, and straightening are the main types of stamping machines.

- Q: The casting sand is going on

- 3, prevention measures(1) to improve the strength of sand mold (core), especially surface strength, high temperature strength, refractoriness, compact, better coating, good core coating and parting surface coating.(2) mould and box can prevent damage;(3) the core should have clearance.

- Q: After reaming, the roughness can reach several levels, that is to say, the sample.Casting parts in rocker arm drilling, reaming, roughness, block. After reaming, the roughness can reach several levels, that is to say, the sample.

- Radial drilling machine can achieve boring, reaming function, but as much as you want, according to your requirements and material to determine!

- Q: What should I pay attention to when designing a casting structure?

- 1 of the casting in metal mold cooling was faster than sand, metal type and let, thus casting in metal mold casting, casting stress generated in the ratio of sand casting to crack tendency is also large, but also prone to misrun and cold lap, white (for casting casting). Defect. Usually: (1) in the prevention of metal casting casting crack aspect should pay attention to the following problems: the structure of A in wall thickness, wall transition and connection to the ease, corner fillet appropriate requirements such as should be more strict than sand casting; B should be connected vertically connected with the wall to tilt C; for the weak parts of the structure should be set to strengthen ribs, bosses, to prevent casting; D should minimize the obstacle free shrinkage of the boss, casting rib, flange and other prominent part; E in the casting arrangement of ribs, but also should consider its influence on the casting shrinkage.

- Q: What is the casting material?

- The casting material is usually made of gray cast iron, nodular cast iron and vermicular graphite cast iron

- Q: What reason is the bronze statue choking fire?

- The casting process in boiling phenomenon, is the setting of the exhaust hole positioner position or number is not reasonable, the air cavity can not be discharged, overwhelmed by a material inlet, reflux, change mould, sincerely help you look forward to adopt,

Send your message to us

EN 214 ductile iron manhole cover with high quality in Hebei Province

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches