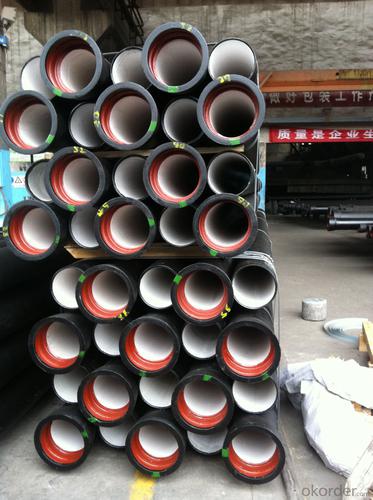

DUCTILE IRON PIPES & FITTINGS K9 CLASS DN100

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 3000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

· Material : Ductile Cast Iron

· Size Range : DN 80mm to DN 2000mm

· Unit Effective Length : 6m or 5.7m

· Manufacture Standard: ISO 2531:1998/ EN 545:2006/EN 598:2007

· Annual capacity : 200,000 tons

· Coating Exterior: Zinc 130g/m2 according to ISO 8179-1 and bitumen coating 70 microns.

· Cement Interior: Portland Cement/ High Alumina Cement/ Sulphate Resisting Cement Lining according to ISO 4179

· Special requirements on external coating and internal lining can be applied

· We also provide accessories such as SBR/EPDM rubber gaskets, lubricant paste, pipe caps, PE sleeves, etc.

Additional Parts:

Each pipe is strictly inspected according to related standard to ensure permanently high performance.

Easy Installation at site and service free for life

Long Service Lifespan

Quotation will arrive you within 24hours once we get your inquiry.

We guarantee offering you a competitive price.

A copy of original inspection reports of pipes will be offered after shipment.

Photos of loading process will be sent to the customer after shipment effect.

We will follow-up the delivery progress after shipment effect and update to the customer on weekly basis.

- Q: What is the relationship between continuous cast iron pipe and ductile iron pipe?

- Cast iron pipes are divided into continuous cast iron pipes and centrifugal cast iron pipes according to different casting methods. They are divided into gray cast iron pipes and ductile iron pipes according to different materials.

- Q: Can ductile iron pipes be used for underground oil and gas pipelines?

- Yes, ductile iron pipes can be used for underground oil and gas pipelines. Ductile iron is a strong and durable material that can withstand high pressure and corrosive environments, making it suitable for such applications. Additionally, its flexibility allows it to accommodate ground movement and settle effectively, reducing the risk of damage to the pipelines.

- Q: How to control mortar proportioning in ductile iron pipe cement coating

- The mixing ratio of ductile iron pipe cement coating mortar is indicated on the design drawings, and the amount of raw material can be calculated according to mortar varieties and mixture ratio.

- Q: How does ductile iron pipe perform in high-velocity flow conditions?

- The performance of ductile iron pipe is exceptional in conditions with high-velocity flow. It can endure the forces exerted by these flows without experiencing significant damage or failure, thanks to its unique properties like high tensile strength and impact resistance. One advantage of ductile iron pipe is its ability to withstand water hammer, which is a sudden increase in pressure caused by the rapid deceleration or change in direction of water flow. This is particularly crucial in high-velocity flow conditions, where water velocity is significantly higher than normal. Ductile iron pipes are designed to absorb and dissipate the energy generated by water hammer, protecting the pipe and the surrounding infrastructure. Moreover, ductile iron pipe has excellent flow characteristics, ensuring smooth and efficient water transport even at high velocities. This is especially important in applications that require quick transportation of a large volume of water, such as industrial processes or fire protection systems. The smooth interior surface of ductile iron pipe minimizes friction and pressure losses, allowing water to flow freely and efficiently, reducing energy consumption and operating costs. Furthermore, ductile iron pipe is highly resistant to corrosion, which is a common issue in high-velocity flow conditions where the water may contain aggressive chemicals or particulates. The protective lining and coating systems used in ductile iron pipes create a barrier against corrosion, prolonging the lifespan of the pipe and maintaining its structural integrity. In conclusion, ductile iron pipe is ideal for high-velocity flow conditions due to its ability to withstand water hammer, excellent flow characteristics, and resistance to corrosion. Its strength, durability, and reliable performance make it a preferred choice for various applications, ensuring efficient water transport even in demanding environments.

- Q: What are the different coatings available for ductile iron pipe?

- There are several different coatings available for ductile iron pipe, each offering unique benefits and protection for various applications. Some of the most commonly used coatings include: 1. Cement Mortar Lining: This coating involves applying a layer of cement mortar to the interior surface of the pipe. It provides excellent resistance against corrosion and abrasion, making it suitable for transporting water and sewage. 2. Bituminous Coating: Bituminous coatings consist of a layer of asphalt or coal tar pitch applied to the pipe surface. This coating offers good protection against corrosion and is often used for underground pipes in water and wastewater systems. 3. Fusion-Bonded Epoxy (FBE) Coating: FBE coatings are created by electrostatically applying a layer of epoxy powder to the pipe surface, followed by curing it at high temperatures. This coating provides exceptional resistance against corrosion and is commonly used in applications where the pipe is exposed to harsh environments or corrosive substances. 4. Polyurethane Coating: Polyurethane coatings offer excellent resistance against abrasion, impact, and corrosion. They are often used for pipes that are exposed to abrasive materials or require additional protection against external damage. 5. Zinc Coating: Zinc coatings, also known as galvanized coatings, involve applying a layer of zinc to the pipe's surface. This coating provides excellent protection against corrosion, making it suitable for pipes that are exposed to moisture and aggressive environments. 6. Polyethylene Encasement: Polyethylene encasement involves wrapping the pipe with a layer of polyethylene film or tape. This coating provides a physical barrier against corrosion and is commonly used in conjunction with other coatings for added protection. It is essential to consider the specific requirements of the application, such as the type of fluid being transported and the environmental conditions, to determine the most suitable coating for ductile iron pipes.

- Q: How are ductile iron pipes made?

- Ductile iron pipes are made through a process called centrifugal casting. In this method, molten iron is poured into a rapidly spinning mold, which forces the iron to evenly distribute along the walls of the mold. As the mold continues to spin, the iron cools and solidifies, forming a hollow cylindrical shape. This process allows the iron to retain its strength and flexibility, making it suitable for use in various piping applications.

- Q: Can ductile iron pipe be used for road and highway crossings?

- Yes, ductile iron pipe can be used for road and highway crossings. Ductile iron is a strong and durable material that is well-suited for underground infrastructure projects, including road and highway crossings. It provides excellent resistance to heavy loads, corrosion, and external forces, making it suitable for withstanding the traffic and environmental conditions associated with road and highway crossings. Additionally, ductile iron pipe is available in various sizes and strengths, allowing for customization based on the specific requirements of the crossing. Proper installation techniques and adherence to relevant industry standards are essential to ensure the longevity and performance of ductile iron pipes in road and highway crossings.

- Q: Ductile iron pipe, socket connection, pipe length, you can cut open it?

- Yes, but the pipe that needs cutting is a cut off pipe with a scissors mark.

- Q: What is the expected hydraulic performance of ductile iron pipes?

- The expected hydraulic performance of ductile iron pipes is generally excellent due to their smooth internal surface, which minimizes friction and pressure drop, allowing for efficient flow of water or other fluids. Additionally, their high strength and durability ensure long-term reliability and minimal leakage, making ductile iron pipes a preferred choice for water supply and drainage systems.

- Q: What is the expected corrosion rate of ductile iron pipes?

- The expected corrosion rate of ductile iron pipes can vary depending on various factors such as the environment, water chemistry, and protective coatings. However, on average, ductile iron pipes typically have a corrosion rate of around 0.1 to 0.5 millimeters per year.

Send your message to us

DUCTILE IRON PIPES & FITTINGS K9 CLASS DN100

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 3000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords