Ductile Iron Pipe ISO8179 DN150-DN900 of Low Price

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 500000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Ductile Iron Pipe Description :

It has high strength & hardnes as steel and better corrosin resistance than steerl and grey iron, I ductile iron pipe is the ideal substute for gray cast iron pipe and common steel pipe. In addition, our DI pipes are produced with good straightness, identical wall thickness, high dimension accuracy, smooth surface finished, remarkable mechanical properties and firmly sticking internal & external coating layer as well. Flexible Push-in joint and rubber gasket are used for more convenient installation of pipelines.

2. Ductile Iron Pipe Main Features:

1. ISO 2531 or EN 545 Standard K9 Class, K7 Class and C Class

2. ISO 9001 Certificate

3. ISO 2531 & EN 545 Certificate

4. WRAS Potable Water Certificate for Cemen Internal Lining

5. WRAS EPDM Rubber Gasket or NBR Rubber Gasket

6. DN80mm - DN2600mm

7. Black Bitumen or Blue Epoxy Coating

8. Lengh = 6m or cut into 5.6m, 5.7m, 5.8m

9. Client's Brand Customization Allowable

10. Container or Bulk Loading / Shipping

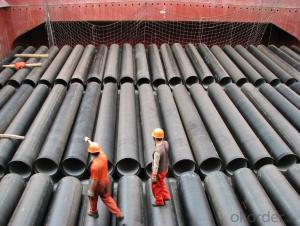

3.Ductile Iron Pipe Images:

4.Ductile Iron Pipe Specification:

1.Standard:ISO2531,EN545,EN598

2.Effective Length:6m/5.7m

3.Internal Lining :Cement mortar, Cement mortar Plus Epoxy

4.External coating:Zinc Primer Plus Bitumen or PE

5. Shipment: By bulk ship or 20'/40' container

6. Rubber: NBR, SBR, EPDM according to ISO4633/EN681.1

7.Quick Delivery

5.FAQ:

Here some questions always been asked

· Industry experience over 20 years.

· Management Systems-Internal Software

· Finished Product Inventory-More Than 5000 Tons.

· Raw Material inventory -Over 8000 Mertic Tons.

· The most convenient transport and prompt delivery.

· Competitive price with best service .

· High technical production line with top quality products.

· High reputation based on best quality products.

- Q: Can ductile iron pipe be repaired if it gets damaged?

- If ductile iron pipe sustains damage, it can indeed be repaired. The process of repair entails the removal of the damaged section and the subsequent substitution with a fresh section. Typically, a pipe cutter, a specialized tool, is utilized to achieve a seamless cut on both ends of the affected area. Once the damaged portion is extracted, a new section of ductile iron pipe is affixed securely by employing mechanical couplings or welding. To safeguard the pipe's integrity and functionality, it is crucial to adhere to the manufacturer's guidelines and industry standards during the repair procedure.

- Q: How are ductile iron pipes protected against internal scaling or buildup?

- Ductile iron pipes are protected against internal scaling or buildup through the use of various coatings and linings. One commonly used method is cement mortar lining, where a layer of cement mortar is applied to the inner surface of the pipe to prevent scaling and corrosion. Additionally, epoxy coatings are also utilized, which provide a smooth and protective layer that inhibits the formation of scale and buildup. These protective measures help to ensure the longevity and efficiency of ductile iron pipes in various applications.

- Q: What is the expected joint restraint method for ductile iron pipes?

- Typically, when it comes to joint restraint methods for ductile iron pipes, the two commonly used options are mechanical joints or push-on joints. Both of these joint types are reliable and prevent leaks, ensuring the stability and integrity of the pipeline system. Mechanical joints involve the use of rubber gaskets and bolts to tightly seal the joints, while push-on joints rely on a groove and rubber gasket system to create a watertight seal. Both methods have excellent joint restraint capabilities and allow for the smooth transmission of fluids or gases through the pipeline without any risk of joint separation or failure. Moreover, these joint restraint methods also make installation and maintenance easier, which is why they are often preferred for ductile iron pipe systems.

- Q: Are ductile iron pipes resistant to seismic events?

- Yes, ductile iron pipes are resistant to seismic events. Ductile iron has excellent strength and flexibility, allowing it to withstand ground movement during earthquakes without fracturing or failing. This makes it a reliable choice for underground infrastructure in areas prone to seismic activity.

- Q: How does ductile iron pipe perform in areas with high groundwater salinity?

- Ductile iron pipe performs well in areas with high groundwater salinity due to its corrosion resistance properties. The iron pipe is coated with a protective layer that prevents corrosion and extends its lifespan, even in saline environments.

- Q: What is the weight of ductile iron pipes?

- The size and wall thickness of ductile iron pipes can cause their weight to differ. Roughly, a 6-inch diameter ductile iron pipe with a length of 10 feet can weigh around 180 pounds. Nevertheless, it is crucial to acknowledge that weight variations may occur among manufacturers due to disparities in their manufacturing techniques and materials. To obtain precise weight information, it is advisable to refer to the product specifications or reach out to the manufacturer.

- Q: Can ductile iron pipes be used in areas with high soil acidity and alkalinity?

- Ductile iron pipes can generally be used in areas with high soil acidity and alkalinity. However, it is important to consider the specific conditions and take appropriate measures to mitigate the potential effects of these soil characteristics on the pipes. In areas with high soil acidity, the acidic conditions can promote corrosion of metal pipes, including ductile iron. To prevent this, protective measures such as applying an external coating or using cathodic protection can be implemented. These measures help to create a barrier between the pipe and the corrosive environment, extending the longevity of the pipes. Similarly, in areas with high soil alkalinity, the alkaline conditions can also have an impact on the performance of ductile iron pipes. Alkaline soils can cause the formation of calcium carbonate deposits, commonly known as scale, which can reduce the flow capacity of the pipes over time. Regular maintenance and cleaning of the pipes can help mitigate the effects of scale buildup. It is worth noting that the suitability of ductile iron pipes in areas with high soil acidity and alkalinity may also depend on the specific grade and quality of the pipes. Manufacturers often provide guidelines and recommendations regarding the use of their products in various environmental conditions. It is advisable to consult with pipe manufacturers or industry experts to ensure proper selection and installation of ductile iron pipes in such areas.

- Q: What does ductile iron pipe "ND200" mean?

- The tube is thin from the metal tube, and the outer diameter of the tube is almost the same as the inner diameter of the tube, so the average value of the outer diameter of the tube and the inner diameter of the pipe is called the diameter.

- Q: Can ductile iron pipes be used in tunneling or microtunneling projects?

- Yes, ductile iron pipes can be used in tunneling or microtunneling projects. Ductile iron pipes are known for their durability, strength, and resistance to corrosion, making them suitable for underground applications. They can handle the pressure and load requirements of tunneling projects and provide reliable and long-lasting performance.

- Q: What is the expected pressure class for ductile iron pipes?

- The expected pressure class for ductile iron pipes can vary depending on the specific application and the requirements of the project. However, generally speaking, ductile iron pipes are designed to handle high-pressure applications and are commonly available in pressure classes ranging from 150 psi (pounds per square inch) to 350 psi. These pressure classes indicate the maximum operating pressure that the pipe can withstand while maintaining its structural integrity. It is important to consult with industry standards and guidelines, as well as the project specifications, to determine the appropriate pressure class for ductile iron pipes in a given situation.

Send your message to us

Ductile Iron Pipe ISO8179 DN150-DN900 of Low Price

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 500000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords