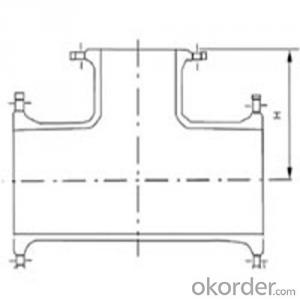

Ductile Iron Pipe Delivery Detail T type DN545 DN200

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Ductile Iron Pipe Description :

DI pipe fittings are manufactured according to ISO 2531 or BS EN545 or BS4772 FOR POTABLE WATER ,internal is cement lining or wet epoxy coating;External is zinc plus bitumen or wet epoxy coating. We also manufacture ductile iron fittings with fusion bonded epoxy both inside and outside. All the producets are sutible to water pipes fields.We have passed ISO9001,ISO14001,OHSMS18001 certificate.

2.Main Features of the Ductile Iron Pipe:

1. Material: Ductile iron grade 500-7/ 450-10 in accordance with ISO1083

2. Standard: ISO 2531, EN545, EN598, ANSI, AWWA

3. Certificate: ISO9001, ISO14001, SGS, NSF, WRAS

4. Test: In accordance with ISO 2531 / EN 545 / EN598 and 100% water pressure test

5. Length: 6m or cut into 5.6m, 5.7m, 5.8m

6. Note: The gaskets, bolts & nuts are supplied respectively as your special requirement

3.Ductile Iron Pipe Images:

4.Ductile Iron Pipe Specification:

Standard: API SPEC 5L 44th eidtion,ASTM A252-98(2007)

Grade: A53 Grades A/B, ASTM A106 Grades B/C,ASTM A179

Weld Alternatives: LSAW

OD size range: 6.4~44.5mm

Wall thickness: 406.4~1422mm

Length: 3 - 12 m according to requirment

Note: Other grade can also be provided after consulting. Special design are available for coal slurry conveyance LSAW line tube -- Service

5.FAQ:

1.Q: Why would you choose ductile iron pipe rather than other pipe materials?

A:The reasons are obvious for that not only ductile iron pipe possesses the inherent strength and flexibility of ductile iron, combined with proven corrosion protection systems, but also the cost savings can be achieved from design to installation and commissioning.

2.Q:Why can you guarantee the inner of pipes can’t be corroded?

A: High alumina cement mortar lining and sulphate-resistant cement mortar lining. These two special linings are applicable to inner anti-corrosion for sewage pipes, improving resistance to erosion of the sewage components.

- Q: does anybody know of a set of irons that are longer,,,yardage wise. i use ping 2 and they are not the longest irons in the barnyard. thanks

- i have demo'd a bunch of game improvement irons and found the taylor made R7's to be the longest i can hit. Several freinds of mine agree. See if you can demo some clubs at an actual driving range - i would think it differs from person to person. But i suggest you give the r7's a try.

- Q: is ferrous Gluconate which is an iron supplement equal to 27mg of iron safe to take?

- Typical iron pills have 324 mg of iron and are called ferrous sulfate Ferrous gluconate is more gentle on stomach, (iron can cause stomach upset) Ask Doctor which form of iron is right for you. Most Doctors do prescribe iron during pregnancy, but too much iron can be dangerous so be sure to get instruction from Doctor, each person is different.

- Q: The top is white and the iron on had words that ended up backwards.The iron on is multicolored and large.

- Iron the area again using the hottest iron setting your shirt can tolerate. While the Iron-on is still hot, peel it away using tweezers. Do not use your fingers, of course, or you will burn yourself. Repeat until you have removed the Iron-on. For the residue left behind.take a thin cotton rag, like an old handkerchief or old sheet. Lay the rag over the residue area. Iron again on a high setting, pressing firmly. Pull the rag away immediately, while still hot. Move to a clean part of the rag and repeat several times. You might not be able to completely remove all residue, but you can try. -

- Q: hi everyone, i have just found out im pregnant, im taking pregnant care vitimins and minerals tablets, as ive heard people say how good they are,im just abit worried as a have a very well balanced diet, so have lots of veg, meat and cereal, which already has iron in it,and also one tablet a day which has 50% reccomended daily allowence of iron, is it dangerous to have this amount of iron in the diet when you are pregnant??

- If what you are taking now is having no obvious effects on you, and the doctor finds that your iron level is ok, then continue as you are. Just beware, there is such a thing as too much iron. During my pregnancy, I took an iron supplement (little red pill) once a day, and was advised to eat Total cereal. That was fine. After I had my baby though, my iron was really low again. My doc told me to continue on the iron pills, but twice a day instead of just once. I started having some pains inside, and after my mom talking to the nurse at her regular doc. office, she said it could be from too much iron. I stopped the pills, and the pains went away. Just to caution you, so you are aware. But like I said, if you are having no problems now with what you are doing, it should be just fine.

- Q: So I am trying to increase my iron levels as I have to give blood soon. Well I picked up an iron supplement and I took one. Well I just realized that it has 65 mg of iron in one pill. Why would they sell these if toxicity is over 50mg. Am I gonna be okay?

- It is great that you are giving blood. However, unless you are suffering from iron deficiency anemia, no amount of iron is going to increase your hemoglobin count. You could take iron after the event, to speed up recovery, but most people do not have a problem in getting back to a normal level. 65mg of elemental iron ( usually in salt of iron about 300mg ) is the treatment dose for simple anemia. Toxic levels for an adult male start at about 700mg of elemental iron daily. If your hemoglobin level is normal, you need no more than 20mg daily for good health. Plenty of foods contain iron including green vegetables and liver

- Q: Iron gate is the deepest gorge in Erope. But i want to know where is that lcated in Euroep.?

- Iron gate located in Romania the last gorge system on the Danube River, dividinate in g the Carpathian and Balkan mountains and forming part of the boundary between Serbia and Romania Coordinate 44° 40′ 16″ N, 22° 31′ 47″ E

- Q: Well I just found a iron but it appears to be old school and really simple is there any avise anybodys got. I kno keep an eye on it. And NEVER set it face down but what else thanks

- Hmmm if you're talking about the VERY OLD iron which uses charcoal to function i'm afraid you have to be really careful when heating it. test it on an unused cloth before trying it on the cloth you want to iron But if you're talking about the electric iron, you have to set its heat appropriate to the type of cloth you're ironing. if you're afraid of ironing it, test it on the ironing board to cool it a bit before trying on the cloth itself and if feel sticky during ironing, try to set the heat a bit lower

- Q: I‘m doing a presentation on the subject and I need to know more about how it works. Also, does anyone knows what are the components needed in order for the iron to function? Or is there anywhere else I can find these information?Thanks!! D

- Well i'm a goodyear person myself, but I haven't heard anything bad about Firestone tires.

Send your message to us

Ductile Iron Pipe Delivery Detail T type DN545 DN200

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords