Ductile Iron fittings

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

China ductile cast iron fittings bend/elbow with flange

Standard:EN545/ISO2531/NBR7675

PN10/PN16/PN25

FBEP/BITUMEN COATING

TAWIL EN545/ISO2531 China ductile cast iron fittings bend/elbow with flange :

Material:ductile iron Pipe Fitting;

Type: All sockets tee or All flange tee or double flange with flange branch tee;

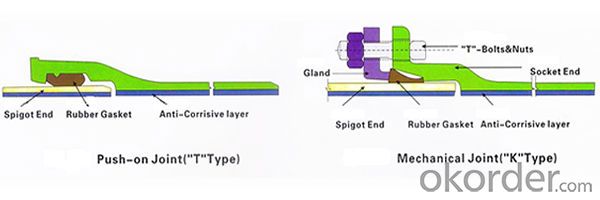

Joint structure: Socket or Flange or mechanical joint or Push-on Joint ;

EN545/ISO2531/NBR7675 ductile iron pipe tee fittings product data:

• Joint structure >>>

• Mechanical Properties >>>

Centrifugal Cast Pipes | Fittings | ||

DN80toDN1000 | DN1100toDN2600 | ||

Tensile Strength | Min.420N/mm2 | Min.420N/mm2 | |

Elongation | Min.10% | Min.7% | Min.5% |

Proof Stress | Min.30N/mm2 | Min.300N/mm2 | |

Hardness | Max.230HB | Max.250HB | |

The proof stress shall be measured only upon special agreement and under conditions which shall be specified in the order.

• Deviation and tolerances on length>>>

The permissible deviation on the standard working length of fittings with sockets and fittings with flanges are given in table as follows:

Type of fitting | Length | Deviation(mm) |

Flanged socket | L | DN80 to DN1200 ± 25 DN1400 to DN2000 ± 35 |

Flanged spigot | ||

Collar | ||

Taper | ||

Bend90° | t | ±(15+0.03DN) |

Bend45° | t | ±(10+0.025DN) |

Bend22.5°and11.25° | t | DN80toDN1000±(10+0.02DN) DN1200toDN2000±(10+0.025DN) |

Tee | L and h | DN80toDN1200-25+50 DN1400todn2000-35+75 |

• Tolerances on manufacturing working lengths>>>

The standard tolerance on the manufacturing working lengths of all fittings with flanges in all nominal size is ±10mm On request in the order and by agreement between the manufacturer and the purchaser,smaller tolerances can be accepted but not less than: ±3mm for DN≤600and±4mm for DN≥700

• Works leak-tightness test>>>

The fitting shall be submitted at the works to a leak-tightness test,carried out either with air at a pressure of 1 par or with water at the pressure given in table as following:

Nominal size DN | Hydrostatic leck-tightness test pressure bar | |||||

Fittings | DI Pipe with weld-on or screwed-on flange | |||||

PN10 | PN16 | PN25 | PN40 | |||

80≤DN≤300 | 25 | 16 | 25 | 32 | 40 | |

350≤DN≤600 | 16 | |||||

700≤DN≤2000 | 10 | |||||

• Internal protection>>>

Spun the blast furnace cement mortar lining complying with the standard ISO4179, or we may offer special protective coating according to customers requirements.

• External Protection>>>

Metallic zinc complying with the standard ISO8179,and bitumen,or we may offer special protective coating according to the customer's requirements.

• Ductile iron pipe fittings-----BEND>>>

- Q: What is a list of some good irons under $800.

- reallly nothing if there stock rims

- Q: What is the Best Professional Flat Iron you have used and why?

- CHI straightening iron, why? well i have naturally oily hair so its can straighten my hair and curl it so that its perfect!

- Q: Would he be Super Iron Man?

- No he would just be Iron Man, because remember the reason Iron Man is Iron Man is because he wears the suit so if Super Man put the suit on then he would just be Iron Man

- Q: I want soft waves, and the iron has to be in the $25 -$40 price range.thanks 4 ur help! :D

- Well if you have a sallys near you just go there. They have some cheap and really nice curling irons.

- Q: during a period or implantation bleeding, if you pass some small clots, is that due to having low iron?? if not, what are clots and why do some poeple pass them while bleeding??

- idk im anemic i dont know what a clot is what is it?

- Q: Okay I get low iron. My doctor gives me iron pills to take. Sometimes my iron gets so low I start to shake really bad My head starts to hurt bad and it starts to spin I drink 1-2 cups of o j and within 5 minutes I‘m fine.

- Orange juice helps with the absorption of iron. Although OJ does need the additional iron. Perhaps your body has trouble absorbing iron. Keep your primary care physician in the loop. Explain that OJ helps you and ask if it is the fact your body is not absorbing the iron. Good Luck Cats

- Q: They gave us a acetate gown for graduation and they told us to use a cool iron. but i just cant get rid of the wrinkles.does anyone know what else i can do with damaging it?

- Put the iron on medium heat. Use a damp hand towel and place the towel over the acetate and press and iron any wrinkles. Then use another dry hand towl to finish the job. Don't iron directly over the seams or they will show through. Iron on either side of the seam and don't iron the top of the hem if there is one. Each sewn seam will show through.

- Q: Could you tell me how to weld ductile iron parts and steel tubes?

- Welding cast iron is mainly in three aspects: carbon control, stress elimination, structural adjustment. You can choose better welding materials, such as WE777 and other imported welding materials. Crack resistance is very good. In addition, the sewing process can be adopted in the structure to increase the stability of the welding effect. You can learn more about WE777 welding applications.

Send your message to us

Ductile Iron fittings

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords