Duct Iron Pipe DI Pipe ISO 2531 DN 80-2000mm Push-on Joint T Type

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ductile iron pipe fittings:

Dimensions standard:

ISO2531: 50-1000mm, PN10/16

BS4772: 50-1000mm, PN10/16

EN545: 50-1000mm, PN10/16

Connecting mode:

Flanged

Socketed

Mechanical connection

Loose flanged

Coatings:

Inner lined with cement and outside coated with zinc plus bitumen

Inner and outside coated with epoxy resin

Inner and outside coated with fusion bonded epoxy resin

Quality:

ISO 2531 or EN 545 Standard K9 Class, K12 Class

1. ISO 9001 Certificate

2. ISO 2531 & EN 545 Certificate

3. WRAS Potable Water Certificate for FBE Internal Lining

4. WRAS EPDM Rubber Gasket or NBR Rubber Gasket

5. DN80mm - DN2000mm

6. Black Bitumen or Blue FBE / Epoxy Coating

7. Lengh = 6m or cut into 5.6m, 5.7m, 5.8m

8. Client's Brand Customization Allowable

9. Container or Bulk Loading / Shipping

10.Delivery within one Month or According to Client's Order Quantity

11. Support Client or The Third Party Inspection before Shipment

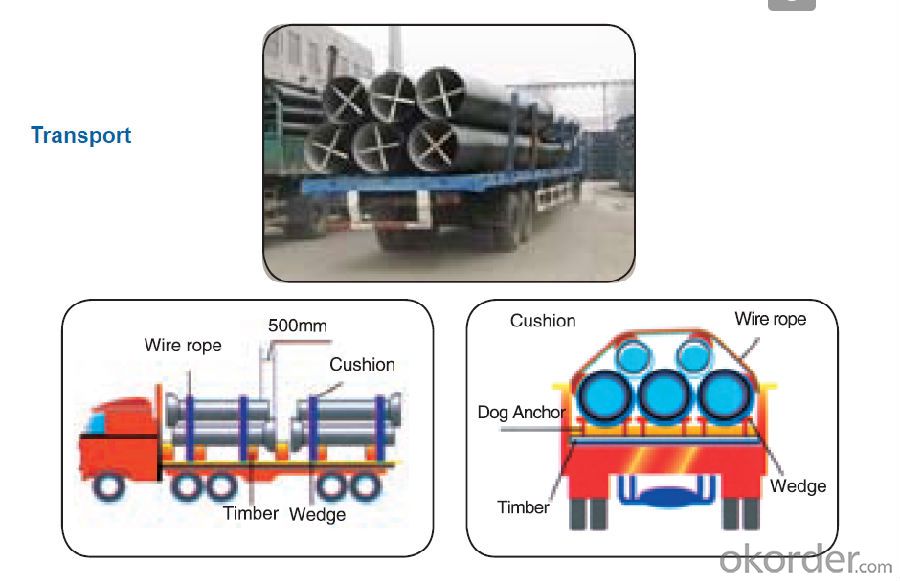

Transport:

- Q: What are the differences between ductile cast iron pipes and centrifugal ductile iron pipes?

- Small, thin pipe fittings are usually rolled or continuously cast, and large, thick pipes are usually centrifugally cast. Compared to sand casting, the tissue is compact and homogeneous.

- Q: Is it better to use steel tubes or ductile iron pipes for water supply?

- Flexible seamless steel pipe is good toughness, good processing, better than ductile iron corrosion resistance, the price is slightly higher;

- Q: How does ductile iron pipe perform in seismic areas?

- Due to its inherent strength and flexibility, ductile iron pipe is highly effective in seismic areas. Seismic activity can cause significant ground movements and vibrations, but ductile iron pipes have shown great resilience in such conditions. The exceptional performance of ductile iron pipe in seismic areas can be attributed to its unique properties, such as its high tensile strength and ductility. These properties enable it to absorb the energy generated during seismic events. Its ability to flex and bend without breaking or fracturing makes it an ideal choice for earthquake-prone regions. Furthermore, ductile iron pipes are specifically designed and manufactured to withstand external forces and ground movements. They are often equipped with flexible joints that can accommodate ground shifts and maintain the integrity of the pipeline system. These joints effectively absorb lateral and angular movements, minimizing the risk of pipe failure. Moreover, ductile iron pipes have a long-standing history of successful performance in seismic areas. They have undergone extensive testing and have consistently met or exceeded industry standards for seismic resistance. This reliability is crucial in ensuring the safety and functionality of water and wastewater systems, even during seismic events. In conclusion, ductile iron pipe is a reliable and durable choice for pipelines in seismic areas. Its ability to withstand ground movements, its flexibility, and its proven track record make it an excellent option for ensuring the integrity and functionality of water and wastewater systems in regions prone to earthquakes.

- Q: Are ductile iron pipes suitable for use in desalination plants?

- Ductile iron pipes are indeed suitable for use in desalination plants. Desalination plants are facilities that remove salt and other impurities from seawater, turning it into fresh water for consumption or industrial use. These plants require a reliable and durable piping system to transport the treated water to various destinations. Ductile iron pipes are known for their strength, flexibility, and corrosion resistance, making them an ideal choice for desalination plants. These pipes are made from a form of cast iron that has been treated with magnesium to enhance its properties. This treatment gives ductile iron pipes a high tensile strength, allowing them to withstand the high pressures associated with the desalination process. Additionally, desalination plants often use chemicals and other treatment methods to remove impurities from the water. Ductile iron pipes have excellent resistance to corrosion from these chemicals and can withstand the harsh conditions found in desalination plants without deteriorating over time. This ensures the longevity and reliability of the piping system, minimizing the risk of leaks or failures. Furthermore, ductile iron pipes have a smooth internal surface, which helps to minimize friction and pressure loss as water flows through the pipes. This feature is especially important in desalination plants, where efficiency is crucial for the overall operation of the facility. The smoothness of ductile iron pipes allows for efficient water flow, reducing energy consumption and optimizing the desalination process. In conclusion, ductile iron pipes are suitable for use in desalination plants due to their strength, flexibility, corrosion resistance, and smooth internal surface. These pipes provide a reliable and durable piping system that can withstand the high pressures, harsh chemicals, and demanding conditions found in desalination plants.

- Q: How does ductile iron pipe perform in areas with high soil stability?

- Ductile iron pipe performs exceptionally well in areas with high soil stability. Its robust and durable nature allows it to withstand the pressures exerted by the stable soil, ensuring a reliable and long-lasting performance. Additionally, the flexibility of ductile iron allows it to accommodate ground movements and settlement without compromising its integrity. Overall, ductile iron pipe is a suitable choice for areas with high soil stability, providing efficient and dependable water distribution and sewerage systems.

- Q: Can ductile iron pipe be used for nuclear power plants?

- Yes, ductile iron pipe can be used for certain applications in nuclear power plants. Ductile iron pipe is known for its strength, durability, and corrosion resistance, making it suitable for various industrial and infrastructure projects. However, when it comes to nuclear power plants, specific factors need to be considered. One of the primary concerns in a nuclear power plant is the safety and reliability of the materials used. While ductile iron pipe meets many requirements, it may not be the ideal choice for critical applications such as transporting radioactive fluids or handling high-pressure or high-temperature systems within the plant. These applications often require materials with exceptional resistance to corrosion, stress, and radiation damage. In nuclear power plants, other materials like stainless steel, nickel alloys, or even specialized materials like Inconel are commonly used due to their superior properties. These materials offer better resistance to radiation-induced embrittlement, corrosion, and high-temperature and high-pressure conditions. Therefore, while ductile iron pipe may have its uses in non-critical applications within nuclear power plants, it is important to consult industry experts, engineers, and comply with relevant nuclear safety regulations to determine the most appropriate materials for specific applications within the plant.

- Q: Can ductile iron pipes be used in gravity sewer systems?

- Yes, ductile iron pipes can be used in gravity sewer systems. Ductile iron pipes are known for their strength, durability, and resistance to corrosion, making them suitable for carrying wastewater under gravity flow conditions.

- Q: How do we handle the leaking of the ductile iron pipe?

- A hoop is a component that holds or ties another material with one material. It belongs to the fastener. The hoop holding device is composed of a hoop plate, a wing plate, a tension tie plate, a bolt and an inner liner. There are many kinds of hoop, hoop cable, wire rod hoop, hoop cable, wire hoop, stainless steel hoop are commonly used.

- Q: How to properly maintain FRP pipes

- The wall of the pipe is smoothReduce flow resistance, increase flow speed and reduce energy consumption. Compared with the same size steel pipe, the flow rate of the same volume can be increased by about 10%, and no fouling and long-term use can not reduce the flow rate. The protection of cables in interference and heavy corrosion environment is better.

- Q: How can the ductile iron pipe be tested?

- Good command of pipe connection must be by hand when a pressure test, must be clear, on the back, pier, interface division, each part of the exhaust valve, must be responsible, then carefully inspected and clear and uniform pressure test.

Send your message to us

Duct Iron Pipe DI Pipe ISO 2531 DN 80-2000mm Push-on Joint T Type

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords