Duck Brand Max Strength Double Sided Medical Rubber Tape Water Based Rubber

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8500 m

- Supply Capability:

- 500000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.product details

| Material: | 100% nylon or Polyester / Nylon |

| Width | 10mm-160mm for your choic |

| Length | 3 meters/5 meters/10 meters/25meters/50meter |

| Feature | self-adhesive, superior strength, eco-friendly and reusabl |

| Color | Main color white,Any color is available |

| Keywords | black and white tape/ hook and loop tape / waterproof adhesive tape / double sided medical tape |

| Applications | Used in garments ,shoes ,textile,hospital etc |

2.Packaging & Delivery

Packaging Details:

90-180 rolls per carton(58*40*30) according to different size

Delivery Detail:

7 to 30 days according to different quantity

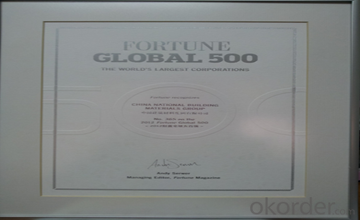

3.Factory and Certification

4.Company information

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win. We will carry on the mutual beneficial, innovative and revolutionary trading structure as we did before, create value for our employees, share holders and clients and benefit the whole society in our future development.

- Q: Are there any regulations or standards for packaging tape?

- Packaging tape is subject to regulations and standards in various countries, like the United States and European Union, to guarantee its safety and effectiveness in securing packages. These regulations encompass material composition, adhesive properties, thickness, tensile strength, and overall durability. Their purpose is to ensure that packaging tape meets specific quality and performance criteria, enabling it to withstand the challenges of transportation and handling without compromising the package's integrity. Furthermore, certain industries may have additional requirements for packaging tape, such as temperature resistance or tamper-evident features. Consequently, manufacturers and users of packaging tape must be aware of and comply with these regulations and standards to ensure the proper functioning and safety of their packaging materials.

- Q: Is packaging tape resistant to moisture or humidity?

- Indeed, packaging tape typically exhibits resistance to moisture and humidity. The majority of packaging tapes incorporate materials like polypropylene or acrylic, renowned for their capacity to endure moisture and humidity. These tapes are purposefully crafted to establish a robust seal on boxes and packages, effectively thwarting the infiltration of water or moisture. Furthermore, packaging tapes frequently boast an adhesive that is meticulously formulated to retain its stickiness, even amidst humid conditions. Nevertheless, it is crucial to acknowledge that the extent of resistance may fluctuate depending on the precise type and caliber of packaging tape employed.

- Q: How do I remove packaging tape without damaging the surface?

- To remove packaging tape without damaging the surface, you can follow these steps: 1. Start by lightly heating the tape using a hairdryer on a low setting. The heat will soften the adhesive, making it easier to remove. 2. Gently lift one corner of the tape using your fingernail or a plastic scraper. Be careful not to use sharp objects that could scratch the surface. 3. Slowly peel the tape back at a 180-degree angle, applying steady and even pressure. If the tape resists, stop and apply more heat to soften the adhesive further. 4. If there is any residue left behind, you can use rubbing alcohol or a mild adhesive remover. Apply a small amount to a soft cloth and gently rub the residue until it lifts off. 5. Once the tape and residue are removed, clean the surface with a mild soap and water solution to remove any remaining adhesive or residue. Remember to always test any cleaning solution on a small, inconspicuous area first to ensure it doesn't damage the surface.

- Q: Can packaging tape be recycled?

- Yes, packaging tape can be recycled, but it depends on the type of tape and the recycling facilities available in your area. Most commonly used packaging tapes, such as clear or brown polypropylene tape, cannot be recycled with regular paper or plastic waste. However, some recycling centers accept certain types of tapes for recycling, such as those made from paper or with water-based adhesives. It is important to check with your local recycling center to determine if they accept packaging tape for recycling and what specific requirements they have. Additionally, removing the tape from cardboard boxes before recycling them can help improve the recycling process. If recycling is not an option, reusing packaging tape or disposing of it properly in the regular trash is recommended.

- Q: Is packaging tape safe to use on painted furniture?

- Yes, packaging tape is generally safe to use on painted furniture. However, it is important to consider a few factors before using it. Firstly, ensure that the paint on the furniture is fully cured or dried, as using tape on fresh paint may cause it to peel off. Additionally, check the type of paint used on the furniture, as some types may be more prone to damage or discoloration from adhesive tape. To be on the safe side, you can test the tape on a small inconspicuous area of the furniture first to see if any damage occurs. It is also recommended to remove the tape carefully and slowly to minimize the risk of any damage.

- Q: Can packaging tape be used for sealing packages with automotive parts or accessories?

- Yes, packaging tape can be used for sealing packages containing automotive parts or accessories. It provides a strong and secure seal to protect the contents during transportation. However, it is recommended to use packaging tape specifically designed for heavy-duty or industrial purposes to ensure optimal durability and adhesion for automotive packages.

- Q: Can packaging tape be used for securing pallet loads?

- Yes, packaging tape can be used for securing pallet loads. It is commonly used to reinforce and stabilize palletized goods by securing them together, preventing shifting or toppling during transportation or storage.

- Q: Is packaging tape safe to use on delicate items?

- The safety of using packaging tape on delicate items varies depending on the type of tape and how it is applied. Certain packaging tapes are specifically made for delicate items, minimizing the risk of damage through features like low tack adhesive or gentle release properties. These tapes, commonly known as "low-tack" or "gentle" tapes, are often transparent. When using packaging tape on delicate items, it is crucial to apply it carefully and securely, avoiding excessive force or pressure. It is recommended to test the tape on a small, inconspicuous area of the item first to ensure it does not cause harm or leave residue. Moreover, it is advisable to wrap delicate items with protective materials like bubble wrap or tissue paper before applying the tape. This extra layer of cushioning and protection can be beneficial. If you are uncertain about the safety of using packaging tape on a specific delicate item, it is always best to consult with the manufacturer or seek professional advice. They can provide guidance on the most suitable packaging materials and methods to ensure the safety of your delicate items during transit or storage.

- Q: Can packaging tape be used for sealing moving boxes?

- Yes, packaging tape is commonly used for sealing moving boxes. It provides a strong and secure seal, ensuring that the boxes remain closed and the contents are protected during transportation.

- Q: Can packaging tape be used for sealing packages with electronic components?

- Indeed, packaging tape possesses the capability to seal packages containing electronic components effectively. Its purpose is to furnish packages with a sturdy and long-lasting seal, safeguarding the contents from external factors like moisture, dust, and physical harm. When sealing packages that house electronic components, it becomes crucial to verify the tape's strength in order to maintain package integrity and offer sufficient protection. Moreover, it is advisable to employ anti-static packaging tape exclusively created for electronic components, as this type aids in the dissipation of static electricity and serves as a preventive measure against potential harm to delicate electronics.

Send your message to us

Duck Brand Max Strength Double Sided Medical Rubber Tape Water Based Rubber

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8500 m

- Supply Capability:

- 500000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches