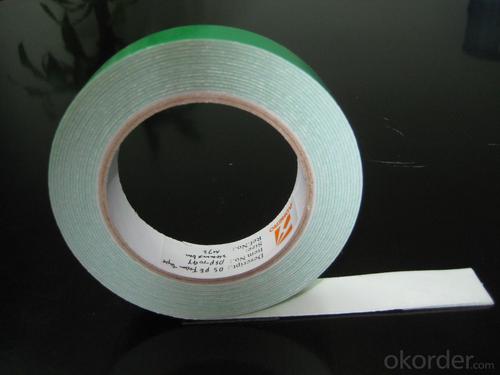

Clear Industrial Packaging Tape - Double Sided EVA Foam Tape with Acrylic Adhesive

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

CONSTRUCTION Of Double Sided Pothook Use EVA Foam Tape:

Backing: EVA Foam (Black/White)

Adhesive: Hot melt rubber adhesive.

Liner: White/Yellow

TYPICAL PHYSICAL PROPERTIES Of Double Sided Pothook Use EVA Foam Tape:

Total Thickness (adhesives + backing): 3 mm

Initial Tack: ≥12# (steel ball)

Peel Adhesion: more than 20 N/25mm (to steel)

Holding power(hrs): 50

Elongation(%): 100

Temperature resistance: 60 Degree Celsius

Sizes Of Double Sided Pothook Use EVA Foam Tape:

Jumbo Roll: 1.00 x 100m

Cut Roll: As per customer’s requirements

Application Of Double Sided Pothook Use EVA Foam Tape:

Holding of minor objects, bond between rough surfaces, reduce vibration & shock.

Bond & adhesion of various hooks, boards, mirrors.

Remarks Of Double Sided Pothook Use EVA Foam Tape:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and be kept away wet and/or heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.

FAQ

Q 1:Do you have any MOQ of your adhesive tape ?

A:Yes, according to the size you need.

Q 2:What is the delivry time?

A:Sample time 7 days, 30 days for the mass production.

Q 3:Can we put our logo on the products?

A :Yes,welcome.

- Q: Are there any regulations or standards for packaging tape?

- Packaging tape is subject to regulations and standards in various countries, like the United States and European Union, to guarantee its safety and effectiveness in securing packages. These regulations encompass material composition, adhesive properties, thickness, tensile strength, and overall durability. Their purpose is to ensure that packaging tape meets specific quality and performance criteria, enabling it to withstand the challenges of transportation and handling without compromising the package's integrity. Furthermore, certain industries may have additional requirements for packaging tape, such as temperature resistance or tamper-evident features. Consequently, manufacturers and users of packaging tape must be aware of and comply with these regulations and standards to ensure the proper functioning and safety of their packaging materials.

- Q: What are the benefits of using UV-resistant packaging tape?

- UV-resistant packaging tape offers numerous advantages. Firstly, it is specifically designed to endure prolonged exposure to sunlight, preventing it from deteriorating or degrading. This is particularly crucial when shipping or storing items outdoors or in areas with direct sunlight. With UV-resistant tape, packages can remain securely sealed for extended periods as it maintains its adhesive properties and structural integrity. Furthermore, UV-resistant packaging tape safeguards the contents of packages from UV ray damage. Sunlight can cause materials like paper, fabrics, or plastics to fade, discolor, or degrade. By utilizing UV-resistant tape, these items are shielded from the harmful effects of UV rays, preserving their quality and appearance. Moreover, UV-resistant packaging tape boasts long-lasting adhesion. Unlike regular tape, which may lose its stickiness over time when exposed to sunlight, UV-resistant tape is specially formulated to bond tightly and securely to various surfaces. This reliable adhesion minimizes the risk of packages opening or items sustaining damage during transit. Additionally, UV-resistant packaging tape provides peace of mind for both senders and recipients. By opting for tape that is resistant to UV rays, businesses and individuals can ensure that their packages arrive in the same condition they were sent, enhancing their professional image and customer satisfaction. This advantage is particularly vital when shipping valuable or delicate items that require extra protection. In conclusion, UV-resistant packaging tape offers enhanced durability, protection against UV damage, long-lasting adhesion, and increased confidence in package integrity. By selecting UV-resistant tape, individuals and businesses can effectively safeguard their packages and their contents, even when exposed to prolonged sunlight.

- Q: Can packaging tape be used for sealing plastic wrap?

- Yes, packaging tape can be used for sealing plastic wrap. It provides a strong adhesive bond that helps secure the plastic wrap in place, keeping the contents protected and sealed.

- Q: How does packaging tape perform on high-friction surfaces?

- Packaging tape typically performs well on high-friction surfaces. Its adhesive properties are designed to provide strong and secure adhesion, even on rough or textured surfaces. The tape's ability to adhere tightly to high-friction surfaces helps ensure the packaging remains intact during transportation and handling, making it an effective choice for securing items on such surfaces.

- Q: Does packaging tape come in different widths for sealing different-sized items?

- Yes, packaging tape is available in different widths to accommodate sealing different-sized items.

- Q: Can packaging tape be used for sealing metal boxes?

- Indeed, metal boxes can be sealed using packaging tape. Specifically engineered to create a secure and long-lasting seal on different surfaces, such as metal, packaging tape possesses a powerful adhesive that effectively adheres to metal, guaranteeing that the box stays sealed throughout storage or transportation. Nevertheless, it is crucial to select a packaging tape appropriate for demanding tasks, capable of enduring the weight and pressure that the metal box may experience. Furthermore, it is advised to cleanse the metal surface prior to applying the tape to ensure optimal adhesion.

- Q: Can packaging tape be used for sealing medical supplies or equipment?

- Using packaging tape to seal medical supplies or equipment is not recommended. Proper and sterile sealing is necessary to maintain the safety and integrity of the contents. Packaging tape is not suitable for medical purposes and may fail to create a sufficient seal. To prevent contamination and guarantee the effectiveness of medical supplies or equipment, it is crucial to utilize sealing materials that meet the necessary standards and regulations.

- Q: Does packaging tape have a specific weight capacity?

- Packaging tape indeed possesses a specific weight capacity. The weight capacity of packaging tape relies on its thickness, width, and overall quality. Typically, packaging tapes are engineered to effectively seal boxes and packages, with their weight capacity determined by their adhesive strength and resilience. The majority of standard packaging tapes can handle a weight capacity ranging from approximately 20 to 30 pounds. Nonetheless, there are heavy-duty packaging tapes available that can manage weights of 50 pounds or more. It is crucial to take into account the weight of the package or box that requires sealing and opt for a packaging tape that can accommodate the precise weight capacity in order to ensure a secure and dependable seal.

- Q: What are the different types of packaging tape available?

- There are several different types of packaging tape available, including transparent tape, brown or tan tape, reinforced tape, water-activated tape, and duct tape. Each type of tape has its own unique properties and is designed for specific packaging needs and applications.

- Q: How does packaging tape compare to duct tape in terms of strength and durability?

- Packaging tape and duct tape differ in terms of strength and durability. While packaging tape is specifically designed for sealing and securing packages, it may not be as strong or durable as duct tape. Duct tape is known for its high strength and durability due to its reinforced backing material, making it ideal for a wide range of applications beyond packaging.

Send your message to us

Clear Industrial Packaging Tape - Double Sided EVA Foam Tape with Acrylic Adhesive

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords