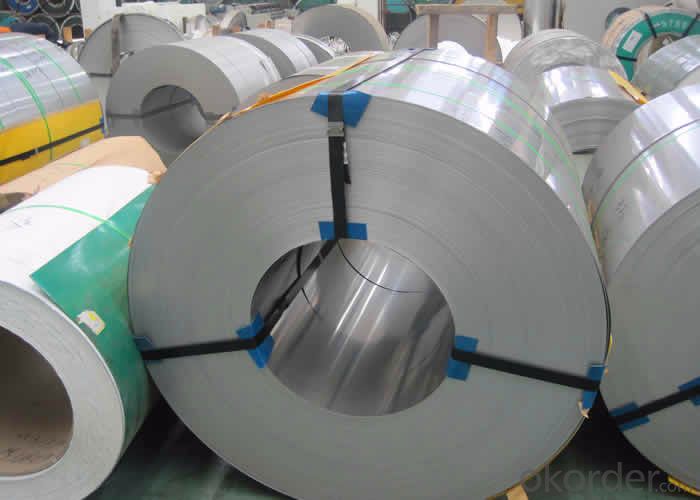

Different Grade Steel Sheet Coil Plate for choice

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Coils and Sheets

Features of Stainless Steel Coils and Sheets:

· Accurate dimension

· Suitable for heavy duty operation

· Minimum maintenance

Specifications of Stainless Steel Coils:

1. Standard: ASTM A240, JIS G4304, G4305, GB/T 4237, GB/T 8165, BS 1449, DIN17460, DIN 17441

2. Grade: 200series&300series&400series

3. Thickness: 0.4mm-50mm

4. Width: 1000/1219/1500/1800mm

5. Length: min 1m

6. Surface finish: 2B, BA, 8K, 6K, Mirror Finished, No1, No2, No4, Hair Line with PVC

7. Manufacture technology: cold drawn/cold rolled/hot rolled

Specifications of Stainless Steel Sheets:

1. Material: 200series&300series&400series

2. Standard: JIS, AISI, ASTM, GB, DIN, EN

3. Thickness: 0.3-100mm or as customer’s requirement

4. Width: 1500-2200mm or as customer’s requirement

5. Length: 1000-6000mm or as customer’s requirement

6. Surface: 2B, BA, No.1, etc

7. Technical processing: Hot Rolled/Cold Rolled

8. Decorative:

Mirror, No.4, HL NSP, Bead Blast, Vibration,

HL Gold, Mirror Gold, Vibration Gold NSP,

No4 Copper NSP, Mirror Copper, Bead Copper,

HL Brass, Mirror Brass, Bead Brass,

HL Black, Mirror Black, Bead Black NSP,

HL Bronz, Mirror Bronze, Vibration Bronze,

Mirror Etched, HL Etched Copper, Mirror Black Etched, Mirror Etched Gold.

Packing Information of Stainless Steel Coils and Sheets:

Please don’t worry that our products are packed, stored, transported according to the international regulation. We do care about the quality of our products; even some little details are paid attention to.

We wrap the stainless steel products with anti-rust paper and steel rings to prevent damage. Identification labels are tagged according to standard specification or customer's instructions. Special packing is available as per customer's requirement.

Plus, our storage racks are made of wood. Other kinds of metals are settled in other places, far from the stainless steel. Any unwanted chemical reaction can be prevented.

Applications of Stainless Steel Coils and Sheets:

1.Automotive:Automotive trim and molding/Difficult-to-form exhaust-system components, tubular manifolds, mufflers/Exhaust manifold and other exhaust-system components, catalytic converter shells, clamps

2. Construction: Gutters and downspouts, roofing, siding

3. Kitchenware: Cooking utensils, dishwashers, ovens, range hoods, refrigerators, skewers

4. Chemical processing: Oil refinery equipment, oil burner and heater parts

5. Appliances: Hot water tanks, residential furnaces

6. Power generation: Heat Exchanger tubing

7. Farming: Dry fertilizer spreaders/Farm animal pens

Technical notes:

Surface Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

- Q: What is the hardness of stainless steel sheets?

- The hardness of stainless steel sheets can vary depending on the specific grade and treatment. However, stainless steel sheets typically have a hardness ranging from 70 to 90 Rockwell B.

- Q: Can stainless steel sheets be used for HVAC systems?

- Yes, stainless steel sheets can be used for HVAC (heating, ventilation, and air conditioning) systems. Stainless steel is a popular material choice for HVAC systems due to its excellent corrosion resistance, durability, and ability to withstand high temperatures. It is commonly used in HVAC applications such as ductwork, vents, and heat exchangers. Stainless steel sheets provide a smooth and clean surface, which helps in maintaining good air quality by preventing the build-up of dust, dirt, and other contaminants. Additionally, stainless steel is easy to clean and maintain, making it a suitable choice for HVAC systems that require regular maintenance and cleaning.

- Q: Are stainless steel sheets suitable for brewery equipment?

- Yes, stainless steel sheets are highly suitable for brewery equipment. Stainless steel is a preferred material in the brewing industry due to its many beneficial properties. Firstly, stainless steel is resistant to corrosion, making it ideal for equipment that comes into contact with liquids and chemicals used in the brewing process. This corrosion resistance helps maintain the quality and purity of the beer being brewed. Additionally, stainless steel is easy to clean and sanitize, which is crucial in maintaining hygiene standards in a brewery. It is non-porous, meaning it does not absorb or retain odors, flavors, or bacteria, ensuring the beer is not contaminated during production. Stainless steel also has a smooth surface, preventing the buildup of bacteria or other contaminants that could affect the quality of the beer. Furthermore, stainless steel is durable and long-lasting, able to withstand the demanding conditions of a brewery environment, including high temperatures, moisture, and constant use. This durability ensures that brewery equipment made from stainless steel sheets will have a longer lifespan, reducing the need for frequent replacement or repairs. Overall, stainless steel sheets are an excellent choice for brewery equipment due to their corrosion resistance, ease of cleaning, sanitation properties, and durability. Using stainless steel in brewery equipment helps maintain the quality and purity of the beer, ensuring a better end product for consumers.

- Q: Are stainless steel sheets suitable for medical equipment or devices?

- Yes, stainless steel sheets are highly suitable for medical equipment or devices. Stainless steel is corrosion-resistant, durable, and easy to clean, making it ideal for use in medical settings where cleanliness and sterility are crucial. It also possesses excellent strength and can withstand high temperatures and harsh environments, making it a reliable choice for medical equipment that needs to endure rigorous use. Additionally, stainless steel is non-reactive, ensuring that it does not interact with medications, bodily fluids, or tissues, which is essential for maintaining the safety and efficacy of medical devices.

- Q: Can stainless steel sheets be used for roofing or cladding?

- Yes, stainless steel sheets can be used for roofing or cladding as they offer durability, corrosion resistance, and a sleek aesthetic.

- Q: Are stainless steel sheets suitable for roofing?

- Yes, stainless steel sheets are suitable for roofing. They have excellent durability, corrosion resistance, and can withstand extreme weather conditions. Additionally, their sleek appearance adds aesthetic value to any building.

- Q: What are the standard dimensions for stainless steel sheets?

- The dimensions of stainless steel sheets differ based on the type and grade of stainless steel utilized. Nevertheless, there exist some widely available common sizes in the market. Typically, the standard width for most stainless steel sheets falls within the range of 36 to 48 inches, while the length can vary between 72 to 120 inches. These dimensions are commonly employed in construction, automotive, and manufacturing applications. The thickness of stainless steel sheets can also vary, with common choices ranging from 0.024 to 0.1875 inches. Thinner sheets are often used for decorative or lightweight purposes, whereas thicker sheets are utilized for heavy-duty applications requiring enhanced strength and durability. It is essential to note that these dimensions are general guidelines and may differ depending on specific project requirements. Moreover, custom sizes can be manufactured to meet the unique needs of a particular application. Overall, the standard dimensions for stainless steel sheets provide a range of options suitable for diverse industries and purposes. This ensures flexibility in selecting the appropriate size for a specific project.

- Q: Can stainless steel sheets be used for stairs and railings?

- Stairs and railings can indeed utilize stainless steel sheets. This remarkably resilient and adaptable material frequently finds its place in architectural and interior design endeavors. With its corrosion resistance, stainless steel proves suitable for outdoor settings and environments with elevated humidity or chemical exposure. The malleability of stainless steel sheets allows for their fabrication into diverse forms and dimensions, rendering them perfect for crafting stairs and railings with an elegant and contemporary appearance. Furthermore, stainless steel boasts effortless cleanliness and maintenance, thus making it a pragmatic selection for high-traffic areas or public spaces.

- Q: What is the lifespan of stainless steel sheets?

- The lifespan of stainless steel sheets can vary depending on various factors such as the grade of stainless steel used, the environment it is exposed to, and the level of maintenance it receives. However, with proper care and maintenance, stainless steel sheets can last for several decades or even longer.

- Q: Are stainless steel sheets good for high-temperature applications?

- Stainless steel sheets prove to be an exceptional choice for applications at high temperatures. With a high melting point that typically ranges from 1400 to 1450 degrees Celsius (2552 to 2642 degrees Fahrenheit), stainless steel becomes suitable for environments with elevated temperatures. Moreover, this type of steel displays remarkable resistance to oxidation when subjected to high temperatures, effectively preventing the formation of scales or rust that could potentially weaken the material. Additionally, stainless steel boasts good thermal conductivity, facilitating efficient heat transfer. These remarkable attributes establish stainless steel sheets as a dependable option for a diverse range of high-temperature applications, such as industrial furnaces, heat exchangers, boilers, and exhaust systems.

Send your message to us

Different Grade Steel Sheet Coil Plate for choice

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords