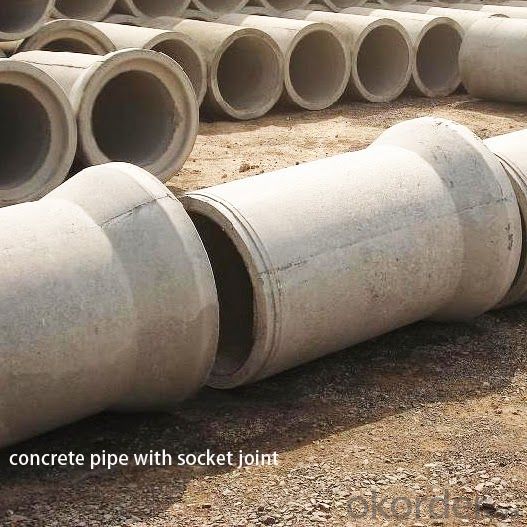

concrete pipe making machine for drainage pipe making

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

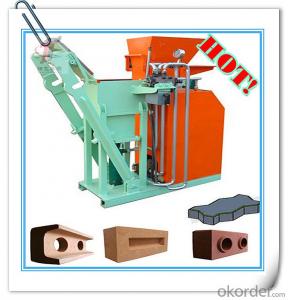

Roller Suspension Concrete Pipe Making Machine is economical, practical, and easy to operate. More than 80% Chinese

pipe making factories use this type concrete pipe making machine.

The machine can produce pipes length up to 4 meters, and diameter from 200mm to 2400mm, flat; socket and rabbet

joints are available.

Hanging roller cement pipe machine is mainly used in municipal engineering, urban and rural construction, drainage

and utility large bridges.

The Concrete Pipe Production Line

Character of Suspension Roller type Concrete Pipe Machine

(1) Short production Cycle: because of the good effect of the roller to compact the concrete, every pipe

just need 3-5 minutes with high speed roller rotation.

(2) This Pipe machine uses the dry cast material, there will no waste cement mud, then it won’t pollute

the environment.

(3) During the production, the noise is low, it is about 80-90 DB

(4) The Concrete Pipes are with high pressure load and with high production efficiency.

Feature:

1. XG series concrete pipe making machine has different types of XG800x2000,

XG1200x2000, XG1600x2000 and XG2000x2000. They produce concrete pipes for

diameter of 200-2, 000mm and length of 1, 000mm to 5000mm.

2. Roller axis support pipe mould and press concrete inside the pipe mould. When

pipe mould with roller axis rotates in high speed, the concrete becomes solid

pipeBy action of roller press and centrifugal force.

Advantage:Equipment Details:

1.First of all,what we supply for you not only the machines,

we will share our experience and technology of concrete pipe making,

There are many pipe making factory around our company.

Seeing is believing, we extend our warm welcome you come to visit us and our factory,

we will show you around our production factory, also our customer factory.

2.Humanize desigh of our machine: easy to switch and the screws with dust proof

3.The bearingarefamous brand with international standards.

4.Strict quality checks in order to the precisionmould.

- Q: How does the pipe machine operate?

- Temporary maintenance in the shift and replacement process time to solve the normal maintenance as planned to complete; all maintenance should be planned, can not be carried out, the hidden dangers of the equipment should be forward-looking, can be done in a timely manner, and ready to deal with ready

- Q: Pipe machine on the bearing what are the requirements

- Equipment with length control device, the next chat length can be set according to their own requirements, can effectively reduce the loss of material head.

- Q: What kind of plastic pipe is divided?

- There are thermoplastic PVC pipe, polyethylene pipe, polypropylene pipe, poly-formaldehyde pipe, ultra-high molecular weight polyethylene pipe; are thermosetting phenol plastic pipe.

- Q: What is the difference between galvanized welded steel pipe and galvanized steel pipe?

- The most commonly used is galvanized steel pipe. Galvanized welded steel pipe application is not very difficult to see

- Q: What is the purpose of each mold of stainless steel pipe machine?

- In the production, the stainless steel pipe machine is mainly used for the production of decorative and industrial stainless steel and carbon steel (round tube, square tube, shaped tube) equipment, stainless steel pipe production mainly through open book, forming, welding, grinding,

- Q: What is the stainless steel pipe machine?

- Hello, stainless steel pipe machine from the machine and many different groups of molds; stainless steel belt from one head into the extrusion through different molds, during the welding by welding, so that steel into a sealed shape.

- Q: The introduction of the pipe machine is

- Such as anti-theft doors and windows, staircase handrails, drinking water pipes, food hygiene pipes, car exhaust pipe, muffler tail pipe, heat exchanger tube, petrochemical pipe, ship pipe.

- Q: Cement pipe machinery and equipment how to work?

- Rotate, then start the feeder from one end of the mold to the other end of the feed, when the concrete is higher than the mold ring 3-5mm, the concrete directly with the spindle contact, relying on the weight of the mold and the weight of concrete compaction reinforced concrete drainage pipe

Send your message to us

concrete pipe making machine for drainage pipe making

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords