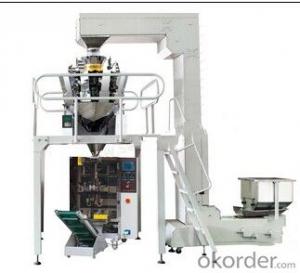

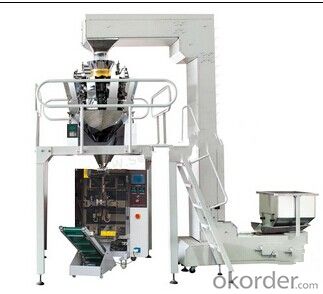

Combined Weighing Full Automatic Packing Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Combined Weighing Full Automatic Packaging Machine System (SK-200DT,SK-220DT)

Model | SK-200DT | SK-220DT |

Air Consumption | 0.65Mpa,2.5M3/min,6kg/cm2 | 0.65Mpa,3M3/min,6kg/cm2 |

Metering Device | 10 Head Combined Weigher | |

Metering Accuracy | ±0.3-1.5g | |

Material Elevator Speed | Max 90 buckets/min | |

Vibrator Speed | Adjustable | |

Take Away Speed | Max 60 bags/min | |

Packing Film Width | 120-380mm | 180-420mm |

Bag Length | 80-240mm | 80-300mm |

Bag Width | 50-180mm | 80-200mm |

Packing Film Roll Diameter | Max.360mm | |

Packing Speed | 5-70bags/min | |

Packing Film Thickness | 0.04-0.08mm | |

Power of SK-200/220 | 220V,50/60Hz,2.4Kw | |

Power of Z type Elevator | 380V,50Hz,750W | |

Power of SK-130 | 220V,50/60Hz,40W | |

Kindly reminder:

Please let us know the follow packing details when you offer,so that we can check if this model is suitable for your case.Thank you in advance.

1. Product details

2. Bag width,bag length

3. Bag shape

4. Packing film material

5. Machine frame

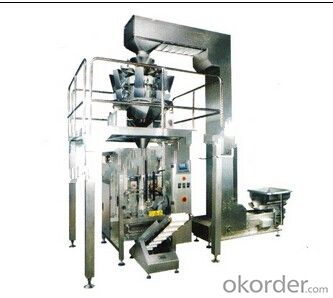

Combined Weighing Vertical Packaging Machine (SK-520DT,SK-620DT,SK-720DT)

Model | SK-520DT | SK-620DT | SK-720DT |

Air Consumption | 0.65Mpa,3M3/min,6kg/cm2 | ||

Metering Device | Ten head combined weigher | ||

Metering Accuracy | ±1% | ||

Material Elevator Speed | Max 90 buckets/min | ||

Vibrator Speed | Adjustable | ||

Take Away Speed | Max 60 bags/min | ||

Packing Film Width | Max 520mm | Max 620mm | Max 720mm |

Bag Length | 80-350mm | 100-400mm | 180-450mm |

Bag Width | 100-250mm | 150-300mm | 180-350mm |

Packing Film Roll Diameter | Max.360mm | ||

Packing Speed | 5-50bags/min | ||

Packing Film Thickness | 0.04-0.08mm | ||

Power of SK-520/620/720 | 220V,50/60Hz,3Kw | ||

Power of Screw Elevator | 380V,50Hz,750W | ||

Power of SK-130 | 220V,50/60Hz,40W | ||

Kindly reminder:

Please let us know the follow packing details when you offer,so that we can check if this model is suitable for your case.Thank you in advance.

1. Product details

2. Bag width & bag length

3. Bag shape

4. Packing film material

5. Machine frame

Combined Weighing Full Automatic Packing System (SK-420DT)

Model | SK-420DT |

Air Consumption | 0.65Mpa,3M3/min,6kg/cm2 |

Metering Device | 10 Head Combined Weigher |

Metering Accuracy | ±0.3-1.5g |

Material Elevator Speed | Max 90 buckets/min |

Vibrator Speed | Adjustable |

Take Away Speed | Max 60 bags/min |

Packing Film Width | 180-420mm |

Bag Length | 80-300mm |

Bag Width | 80-200mm |

Packing Film Roll Diameter | Max.360mm |

Packing Speed | 5-70bags/min |

Packing Film Thickness | 0.04-0.08mm |

Power of SK-200/220 | 220V,50/60Hz,2.4Kw |

Power of Z type Elevator | 380V,50Hz,750W |

Power of SK-130 | 220V,50/60Hz,40W |

Kindly reminder:

Please let us know the follow packing details when you offer,so that we can check if this model is suitable for your case.Thank you in advance.

1. Product details

2. Bag width,bag length

3. Bag shape

4. Packing film material

5. Machine frame

- Q: What is the general packing cost of beer beverage packaging?

- In addition, according to the product's own conditions to set, the packaging machine prices are generally in the range of 3-5 yuan

- Q: What are the main functions of packaging machinery?

- Eight main functions of packaging machinery and equipmentPacking is a necessary condition for products to enter the circulation field

- Q: What are the main plastic forming processes?

- 5. low pressure molding. A touch or laminating method using a molding pressure equal to or less than 1.4 mpa.Low pressure molding is used to make reinforced plastic products. Reinforced materials such as glass fiber, textiles, asbestos, paper, carbon fibers, etc.. Most resins used are thermosetting, such as phenolic, epoxy, amino, unsaturated polyester, silicone and other resins.Low pressure molding includes bag pressing and spraying.(1) bag pressing forming. A method of forming a workpiece by applying fluid pressure to an elastomeric plastic between a rigid mold and an elastic bag by means of an elastic bag (or other flexible diaphragms). According to the different methods caused by fluid pressure, can generally be divided into pressure bag molding, vacuum bag molding and autoclave molding etc..(2) spray forming. When molding reinforced plastic products, a method of spraying a short cut of fibers and resins simultaneously onto a mold and solidifying them into an article by means of an airbrush is described.

- Q: Ask a mechanical problem, the waste film recycling in the packaging machinery is a new film packaging, after cutting, then use the roller to recycle the waste film. Encounter a

- It is suggested that displacement or velocity should be detected on the transport path of the membrane. Is a more reliable control signal. Of course, you can also detect the angular speed of the recovery drum, such as a code dial and other simple institutions.

- Q: The role of packaging equipment in packaging equipment

- Packaging is the necessary condition for products to enter the circulation field, and the main means of packaging is the use of packaging machinery. With the development of the times and the progress of technology, packaging equipment is playing a more and more important role in the field of packaging. The main functions of packaging equipment are as follows:

- Q: How much is the tableware wrapping machine?What's the price of the tableware wrapping machine?

- Tableware packing machine? Should the packing of the tableware be contracted? Tak Cheung packing machinery, automatic heat shrinkable tableware packing machine can be considered

- Q: Is there anyone who knows what groups of users of packaging machinery are in general?

- If automated packaging, it depends on the factory situation, should not be from the user groups to start. If a small class of cosmetics do, then he will not say to buy a more than ten thousand or hundreds of thousands of automated equipment to pack ah. Automatic packing machine is certainly need a certain amount, a certain basis will be needed, or buy a mechanical automation a month the amount of packaging takes less than one hour, then buy this station automation machinery to do what? So, according to the automatic device, we can not start from the user groups, should be considered from the size of the factory.

- Q: What are the structures of the packaging machinery?

- Is a professional engaged in "packaging machinery" research and development, production, sales as one of the multinational enterprise groups. It is the largest manufacturer of packaging machinery in china. Located in the Chinese science and Education City - Hefei, the geographical position is superior, the traffic condition is convenient, and the sale network extends the whole country. Is far from, with a group of the world's top machinery manufacturing R & D team, specializing in all walks of life packaging enterprises, for the efficient production of enterprises to provide power. It is a large enterprise that put forward the concept of packaging automation earlier in china. Brand with strong economic strength, first-class R & D level, advanced business philosophy and good brand service, more and more people all over the world are respected and trusted. The entire manufacturing process in full accordance with the highest standards of global manufacturing; at the same time according to the quality standard of global market development process, operating procedures and quality control system of production, all is "far Machinery" have reached world-class standards. "Far distance machinery" combines the characteristics of all kinds of products in China, such as packaging machinery, food packaging machines, two times packaging machines, powder packaging machines, particle packaging machines, liquid packaging machines, weighing machines, and so on.

- Q: What are the packaging machines that use temperature control watches?

- Direct heating sealing machine, blister packing machine, plastic sealing machine, heating pot, oven, toaster and so on

- Q: Energy saving reform of packaging machine

- Due to the adoption of variable frequency speed regulation, the chain drive is greatly reduced, the stability and reliability of the operation of the machine are improved, and the noise of the machine operation is reduced. It guarantees the high efficiency, low loss and automatic detection of the packaging machine. It has both a beautiful and fashionable appearance, and a healthy and smart mind.Although the transmission system used in food packaging machine is relatively simple, it has higher requirements for the dynamic performance of the transmission. The system requires fast dynamic follow-up performance and high stability speed accuracy. Therefore, we must consider the dynamic technical indicators of inverters, and select high-performance inverter to meet the requirements.

Send your message to us

Combined Weighing Full Automatic Packing Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords