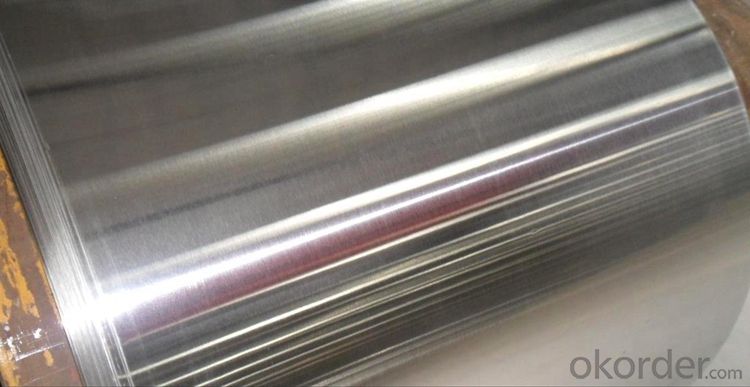

Cold Rolled Stainless Plates NO.2B Finish

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description for Stainless Steel Coils/Sheets:

Material | 201/202/301/304/304L/310S/316/316L/321/410/420 |

Technique | old Rolled, Cold Drawn, Hot Rolled |

Standard | ASTM,AISI,JIS,GB,DIN,EN |

Thickness | 0.3mm-100mm or as your requirement |

Width | 100mm-3000mm or as your requirement |

Length | 1000mm-10000mm or as your requirement |

Surface Treatment | BA,2B,No.1,No.4,No.8,HL,8K,Brush |

Packing | 1.Export sea worthy package + water proof paper + wooden pallet 2. Max Loading 26.5mt for each 20Gp container 3.Safe loading and fixing Professiona teams 4. Professional shipping line |

Delivery | 25 days after received the 30% deposit of T/T or L/C |

Payment | T/T,30%payment in advance,70%T/T after the copy of B/L or L/c at sight |

Application | Stainless Steel Sheets are widely used in below fields: 1: Construction field, shipping building industry 2: Petroleum and Chemical Industries 3: Food and Mechanical Industries |

Specifications for Stainless Steel Coils/Sheets:

Type | 200 series,300 series,400 series |

Thickness | 1.8-8.0mm |

Widthness | 1000/1219/1500mm |

Technique | Hot Rolled/Cold Rolled |

Coil Weight | About 20 Tons |

Finish | NO.1/NO.2B |

Place of Origin | Made in China |

MOQ | 18 ton |

Color | Black,Mirror Finished |

Standard | ASTM, JIS, GB, BS, DIN etc |

Exporting countries | Peru,India,Pakistan,Singpore,Vietnam,South Korea,Malaysia etc. |

After-sales service | Factory Inspection |

Certifications | ISO,SGS |

Packaging | Standard export packing or following customer's demand |

Application for Stainless Steel Coils/Sheets:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

Detail picture for Stainless Steel Coils/Sheets

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

Export Markets for Stainless Steel Coils/Sheets:

Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q: Can stainless steel sheets be used in architectural applications?

- Yes, stainless steel sheets can be used in architectural applications. Stainless steel is a versatile material that offers durability, corrosion resistance, and aesthetic appeal, making it suitable for various architectural purposes such as cladding, roofing, decorative elements, and structural components. Its sleek, modern look and ability to withstand harsh environmental conditions make stainless steel sheets a popular choice in the construction industry.

- Q: How do I prevent warping on stainless steel sheets?

- To prevent warping on stainless steel sheets, it is important to ensure proper handling and storage practices. Avoid placing heavy objects on top of the sheets, as this can cause them to bend or warp. Additionally, store the sheets in a clean and dry environment to prevent moisture absorption, which can also lead to warping.

- Q: Are stainless steel sheets suitable for water tanks?

- Yes, stainless steel sheets are suitable for water tanks. Stainless steel is highly resistant to corrosion and rust, making it an ideal material for water storage. It is durable, long-lasting, and can withstand high water pressures. Additionally, stainless steel is hygienic, easy to clean, and does not contaminate the water.

- Q: Are stainless steel sheets resistant to UV rays?

- Yes, stainless steel sheets are resistant to UV rays. Stainless steel is known for its durability and corrosion resistance, and this extends to its ability to withstand exposure to UV rays. The chromium content in stainless steel forms a protective oxide layer on the surface, which helps prevent the metal from oxidizing or corroding when exposed to sunlight. This oxide layer acts as a barrier that shields the stainless steel from UV rays, making it highly resistant to the damaging effects of prolonged sun exposure. Therefore, stainless steel sheets are an excellent choice for outdoor applications where UV resistance is a requirement, such as roofing, cladding, and architectural elements.

- Q: How long do stainless steel sheets last?

- Stainless steel sheets are known for their durability and longevity. In general, the lifespan of stainless steel sheets can vary depending on various factors such as the grade and quality of the stainless steel, environmental conditions, and maintenance practices. However, under normal circumstances and proper care, stainless steel sheets can last for several decades or even a lifetime. The corrosion-resistant properties of stainless steel play a crucial role in its longevity. This material contains chromium, which forms a passive layer on its surface, protecting it from rust and corrosion. This natural protective layer allows stainless steel sheets to withstand harsh environmental conditions, including exposure to moisture, chemicals, and extreme temperatures. The grade of stainless steel also affects its lifespan. There are different grades available, such as 304, 316, and 430, each with varying levels of corrosion resistance. Higher grades, particularly 316 stainless steel, are more resistant to corrosion and are commonly used in marine and highly corrosive environments, ensuring a longer lifespan. Proper maintenance is essential to maximize the lifespan of stainless steel sheets. Regular cleaning with mild detergents and non-abrasive materials helps to remove dirt, grime, and contaminants that can degrade the protective layer of stainless steel. Avoiding contact with harsh chemicals or abrasive materials, which can scratch or damage the surface, is also crucial. While stainless steel sheets have an impressive lifespan, it is important to note that their durability is not indefinite. Over time, factors such as wear and tear, exposure to severe conditions, or improper maintenance can gradually degrade the stainless steel's protective layer and reduce its lifespan. However, with proper care and maintenance, stainless steel sheets can be a cost-effective and long-lasting choice for various applications, including construction, automotive, and household products.

- Q: What is the minimum thickness of stainless steel sheets available?

- The minimum thickness of stainless steel sheets available can vary depending on the manufacturer and the specific grade of stainless steel being used. Generally, the thinnest stainless steel sheets available range from 0.4mm to 0.5mm. However, it is important to note that some manufacturers may offer thinner sheets, such as 0.3mm, but these may be more specialized or less commonly available. If you require a specific thickness for your project, it is recommended to consult with stainless steel suppliers or manufacturers to determine the options available to you.

- Q: Can stainless steel sheets be used for oil and gas pipelines?

- Indeed, oil and gas pipelines can utilize stainless steel sheets. The oil and gas industry frequently relies on stainless steel because it possesses remarkable resistance against corrosion. It can endure the demanding circumstances involved in the transportation and storage of oil and gas, encompassing high pressure, high temperature, and corrosive surroundings. When constructing pipeline components like pipes, fittings, and flanges, stainless steel sheets are commonly employed. They provide longevity, robustness, and the ability to resist corrosion, thereby aiding in leak prevention and the preservation of pipeline integrity.

- Q: How do you determine the best thickness of stainless steel sheet for a specific application?

- Several factors need to be taken into account when determining the optimal thickness of a stainless steel sheet for a specific application. First and foremost, the intended use of the stainless steel sheet is of utmost importance. Different applications necessitate varying levels of strength, durability, and resistance to corrosion. For instance, if the sheet will be employed in a high-stress environment or exposed to harsh chemicals, it would be prudent to opt for a thicker gauge stainless steel sheet in order to ensure sufficient strength and corrosion resistance. In addition, the size and dimensions of the application must be considered. Larger structures or components may necessitate thicker stainless steel sheets to maintain structural integrity and prevent deformation under load. Conversely, smaller or more delicate applications may benefit from thinner sheets to reduce weight and enhance flexibility. Furthermore, it is crucial to take into account the expected lifespan and maintenance requirements. Generally, thicker stainless steel sheets offer greater longevity and can withstand more wear and tear. However, if the application calls for frequent cleaning or maintenance, a thinner sheet may be more practical. Budgetary constraints should also be factored in. Thicker stainless steel sheets tend to be more costly due to the increased material expense and manufacturing complexity. Striking a balance between desired performance and available resources is crucial in determining the most cost-effective thickness. Lastly, seeking insights from industry standards, guidelines, and experts can be invaluable. Different industries have specific requirements for stainless steel sheet thickness based on their experiences and safety standards. Engaging with professionals can help ensure that the chosen thickness meets the necessary specifications and regulations. In conclusion, the determination of the optimal thickness of stainless steel sheet for a specific application involves considering the intended use, size, expected lifespan, maintenance requirements, budget, and seeking expert guidance. By carefully evaluating these factors, one can make an informed decision and select the most suitable thickness for their specific needs.

- Q: Can stainless steel sheets be used in medical equipment?

- Medical equipment can indeed make use of stainless steel sheets. Due to its exceptional properties like resistance to corrosion, durability, and ease of cleaning, stainless steel is a favored option for medical devices and equipment. It is frequently employed in surgical instruments, implants, hospital equipment, and laboratory tools. The versatility of stainless steel sheets makes them a common choice in the manufacturing of medical equipment as they can be shaped into various forms and sizes. Furthermore, stainless steel is highly biocompatible, meaning it poses no harm to bodily tissues and can be safely used in medical applications. All in all, stainless steel sheets are a dependable and widely accepted material for medical equipment, offering both hygienic qualities and long-lasting performance.

- Q: How do you prevent galling when using stainless steel sheets?

- To prevent galling when utilizing stainless steel sheets, there are several precautions that can be taken: 1. Lubrication: Apply an appropriate lubricant or anti-seize compound to the contact surfaces in order to decrease friction. This will establish a barrier between the stainless steel sheets, preventing sticking and galling. 2. Ensure proper surface finish: Verify that the stainless steel sheets possess a smooth surface finish. Rough or uneven surfaces heighten the likelihood of galling. Consider implementing sheets with a polished or finely ground finish to minimize the chance of galling. 3. Regulate contact pressure: Refrain from applying excessive pressure when working with stainless steel sheets. Excessive pressure generates heat and intensifies friction, leading to galling. Adjust the pressure to a level that allows for smooth movement without excessive friction. 4. Decrease sliding or rubbing: Diminish the amount of sliding or rubbing between stainless steel sheets. If feasible, employ rolling or lifting techniques instead of dragging or sliding the sheets against each other. This will minimize the risk of galling by reducing the contact area and friction. 5. Utilize compatible materials: When utilizing stainless steel sheets in conjunction with other materials, ensure compatibility. Certain materials, such as aluminum or specific coatings, can promote galling when in contact with stainless steel. Opt for materials that are less prone to galling or utilize protective coatings to prevent direct contact. 6. Avoid excessive heat: Excessive heat heightens the likelihood of galling in stainless steel sheets. Guarantee that the temperature is controlled and does not reach levels that could significantly heat up the sheets. This can be achieved through proper cooling methods or by implementing heat-resistant materials, if necessary. By adhering to these preventative measures, the risk of galling when utilizing stainless steel sheets can be significantly reduced. This will result in smooth operation and prolong the lifespan of the sheets.

Send your message to us

Cold Rolled Stainless Plates NO.2B Finish

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords