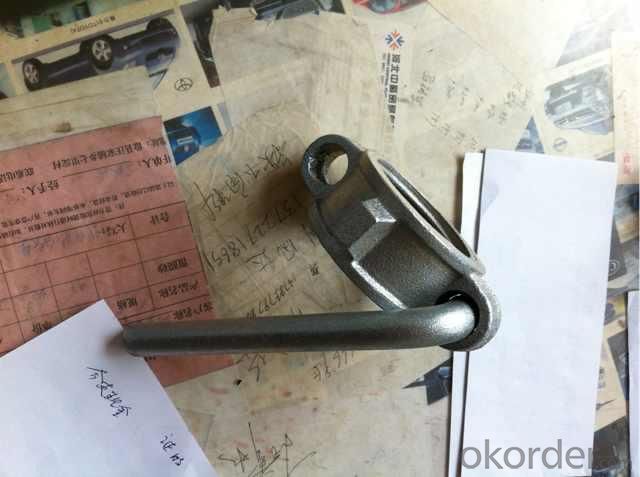

Cold Galvanized Prop Nut With Handle Dia 48 mm

- Loading Port:

- XINGANG

- Payment Terms:

- TT

- Min Order Qty:

- 2000 Unit/Units set

- Supply Capability:

- 5000 Unit/Units Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Cold Galvanized Prop Nut With Handle Dia 48 mm

Place of Origin: China (Mainland)

Brand Name: CMAX

Type: Scaffolding Parts

Scaffolding Part Type: Scaffolding Props

surface: cold galvanized

Specifications Cold Galvanized Prop Nut With Handle Dia 48 mm

1.Material:Steel

2.Size: 48MM

3.Surface treatment:Zinc Plated

4.Prop Nut With Steel Handle

5.Name:Prop Nut With Steel Handle

|

Name |

Size |

Weight |

Packing |

Material Surface |

|

Collar nut |

DIA.48/60MM DIA.60/77MM |

0.46KG 0.97KG |

In woven bag or as per your request, about25MT/20'GP |

White/color galvanized, or plain |

Packaging & Delivery of Cold Galvanized Prop Nut With Handle Dia 48 mm

Packaging Detail: IN WOVEN BAG/GUNNY BAG, OR IN PALLET

Delivery Detail: 30 DAYS AFTER ORDER CONFIRMED

Specifications of Cold Galvanized Prop Nut With Handle Dia 48 mm

Casting prop nut

Material: casting or forged

Various specifications available.

Surface: Plain, white galv. or color galv.

BV CERTIFICATION FOR ALL OUR CASTING PRODUCTS.

Specifications of Cold Galvanized Prop Nut With Handle Dia 48 mm

1) Available either in malleable casting for light work or drop forged for heavy duty job.

2) Surface: PLAIN FINISH, white galvanized, hot dipped galvanized, color galvanized

3) Handle can be threaded or non threaded.

4) Weight: 0.42kg or as customers request

Details of Cold Galvanized Prop Nut With Handle Dia 48 mm:

1. Raw Material: ductile iron or forged carbon steel

2. Weight: 0.46kg or as customers request

3. Standards: BS or DIN related standards

4. Non-standard specification is available.

We are manufacturer for many years , all our casting products are exported to middle east, east and south Asia, and Europe market, BV certification make our products win high reputation from our customers.

We can supply most of the casting or forged parts & accessories for scaffolding,ring-lock system, cup-lock system and formwork, please feel free to contact with us for whatever you are interested.

- Q: What are the maintenance and maintenance of hydraulic climbing formwork

- After the shift between the device and the main girder is inserted on the pin and the pin card, after the shift is already used for rear jacking jacking, wind cable is tightened, the adjacent frame between the climbing frame is firmly rachel.

- Q: Climbing frame is divided into several kinds, what is its running mode? What is the rental cost? Please explain in detail! Thank you very much

- Install the lifting seat and a guide seat is connected with the high wall, main frame vertical rod, the frame set up to the designed height, laying the top scaffold, block feet - laying bottom safety nets and scaffolding, making turning plate - the upper part of the frame body structure and effective tie (tie spacing is not greater than 6m) - display efflux dense mesh safety net to the top of the shelf, the anti dropping boom is inserted into the base anti dropping device, the installation of steel rope - placed distribution cables, installation control cabinet, electric hoist, electric wiring and debugging system, pre inspection, electric hoist, demolition of frame body and the upper structure of pulling and synchronization a layer - installation completed, enter the upgrade cycle

- Q: The difference between the scaffold and the scaffold

- The difference between climbing frame and scaffolding is commonly used scaffolding from below has been set up, which is followed by building up climbing frame, the figure is upstairs, they have in common is that we are like scaffolding

- Q: Advantages and disadvantages of climbing frame and floor type scaffold

- 3, compared with the economy, the processing is simple, and the investment cost is low; if the geometric dimensions of the scaffold are carefully designed, and the utilization rate of the steel tube is improved, the material consumption can also obtain better economic effect. Fastener steel pipe frame equivalent to 15 square meters per square meter of construction steel.

- Q: The whole concrete wall climbing frame or good use of steel scaffolding

- Climbing frame, also known as the lifting frame, according to its source of power can be divided into hydraulic, electric, manual pull and other major categories. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction

- Q: What is an integrated climbing frame? What are the works? What are the advantages

- . It can climb up or down the building. This system makes the change scaffolding Technology: one is without turning over the shelf; two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1987 |

| Annual Output Value | Below US$1 Million |

| Main Markets | China; United States; Britain; Japan; Germany; Israel |

| Company Certifications | GB/T19001-2008/ISO9001:2008 Quality Certification |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Xingang |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 10-20 people |

| Language Spoken: | Chinese; English |

| b) Factory Information | |

| Factory Size: | Above 3,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Cold Galvanized Prop Nut With Handle Dia 48 mm

- Loading Port:

- XINGANG

- Payment Terms:

- TT

- Min Order Qty:

- 2000 Unit/Units set

- Supply Capability:

- 5000 Unit/Units Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords