Coated aluminum foil for food container FOR 8011

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Quick Details

| Temper: | Half Hard | Use: | Kitchen Use | Treatment: | Coated |

| Type: | Roll | Alloy: | 8011 | Thickness: | 0.05-0.5mm |

| Place of Origin: | China (Mainland) | Brand Name: | Model Number: | HO | |

| Color: | Silver | Application: | Food packaging |

Packaging & Delivery

| Packaging Details: | according to customer's requirements |

| Delivery Detail: | 40days |

The specification of aluminum foil:

1)Width:30-900mm,to cut as your requirement

2)Thickness:0.07-0.12mm,allowable error:0.005mm

3)Alloy:8011

4)Temper:HO

5)Coating:ployester

6)Color:Various colors are available.We also can make in accordance with your own color range.

7)Gloss:meet the coustomer's requirement

8)Packaging Detail:standard export packing

The performance of aluminum foil:

1)Health and safety,there are no stains on surface.

2)The coating is very thick and homogeneous.

3)High temperature resistant,no any distortion and color change.

4)Double-faced coating is 3.5-4.2g/m2.

5)The paint won't peel off when the processing equipment in it.

6)Good gloss,chromatic aberration is not identify by eyeballing.

7)It's the best materials for food container.

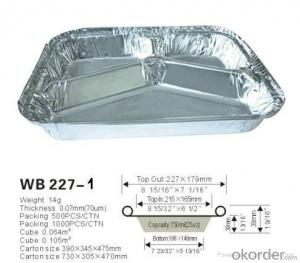

specification:

1.thickness:9 mic,10 mic,11 mic 12mic,14 mic 15mic,18 mic,20 mic,30 mic

2.width:100mm,120mm,150mm,250mm,300mm,450mm,500mm,600mm

3.length:3-300m(10-1000ft)

4.coreID:25mm,30mm,32mm,35mm,38mm,40mm,42mm,45mm,50mm

5.packing: color box,OPP bag,shrinking bag.

- Q: The working principle and characteristics of hand held aluminum foil sealing machine

- 1. Choose the flat surface, steady the machine, insert the joint of the inductive head into the socket on the front panel of the machine and screw it tightly. Pay attention to the orientation of the socket.2. One end of the plug of the power cord is inserted into the power supply socket on the rear plate of the machine case, and the other end is inserted into the power supply socket, and the single-phase three wire power supply must be used. Voltage 220V, socket can withstand more than 10A current.3. Turn on the power switch on the rear panel of the cabinet. The sealing time of the control panel is bright and the machine can work.4, press and hold the time setting button, according to the need to seal the diameter of the container, material set a suitable value, setting value between 0.1-3.9 seconds.5, the container alignment of the sensor head of the center (previously placed induction aluminum foil container cover and tighten the membrane compaction) by induction power switch on the handle, then the original set time countdown to zero, said the work has been completed, and then remove the sensor head container under a sealing operation.6, check the sealing quality, according to different materials, diameter containers, as well as production efficiency, appropriate trimming time setting button, so that the sealing quality to the best.7, do not work, press the power switch on the front panel closed.

- Q: Does the FFC package foil have no grounding, which is equivalent to adding a capacitor to the cable?

- If both ends are not grounded, it should be equivalent to the effect of adding an inductor (somewhat like the use of a magnetic ring).If there is a parasitic capacitor, it exists everywhere, but the size of the parasitic capacitance.

- Q: Relationship between capacitor capacity and aluminum foil

- The capacitance C of the parallel plate capacitor is directly proportional to the dielectric constant epsilon, inversely proportional to the area, and inversely proportional to the distance d between the platesC= epsilon S/4 PI KDK is static electric constant in the formula

- Q: Must there be foil wrapper in the Tea Caddy?

- This really doesn't need it. As long as the container containing tea, the sealing effect is good. The family keeps the tea as long as it keeps dry and doesn't mix. For reference only.

- Q: What's the flow of aluminum foil statistics?

- There are two ways to produce aluminium foil: rolling and vacuum evaporation (see deposition foil material production).

- Q: Aluminum foil lunch box microwave oven operation method?

- That depends on what kind of aluminum foil lunch box, coated with, for example, rainbow aluminum foil lunch box.Specific use: be sure to open the lid, food should not be too full, placed in the middle of the microwave oven.Hope to adopt, thank you!

- Q: Is the quality of aluminium foil lunch box good? It looks good. Ha, it looks pretty tall. I don't know if it's reliable

- Really haven't seen, general take away boxes are transparent plastic, feel first is not green, second will be toxic

- Q: Hand held aluminum foil induction sealing machine, how long is the sealing time?

- Handheld aluminum foil sealing machine use environment:Handheld foil sealing machine maximum ambient temperature 45 degrees centigrade, relative humidity not higher than 80%, the machine should be placed in a well ventilated environment, cooling hole induction power supply side and bottom heat radiating holes and inductive head to ensure clean and smooth. Excessive temperature or humidity will have a great impact on the life of electronic components, and even lead to damage to the equipment.

- Q: Dcgy-500 type aluminum foil sealing machine is out of order, it is not sealed, burned out which element, how to fix?

- Recommend a small number of products, practical handheld aluminum foil sealing machine. It is the first choice for small businesses to save equipment costs. This machine can adjust sealing power according to sealing size. The bottle neck can be used between 20 and 100 millimeters in diameterHandheld aluminum foil sealing machine use environment:Handheld foil sealing machine maximum ambient temperature 45 degrees centigrade, relative humidity not higher than 80%, the machine should be placed in a well ventilated environment, cooling hole induction power supply side and bottom heat radiating holes and inductive head to ensure clean and smooth. Excessive temperature or humidity will have a great impact on the life of electronic components, and even lead to damage to the equipment.

- Q: Where is the use of high pressure etching into electronic aluminium foil?

- In the family of electrolytic capacitors, aluminum electrolytic capacitors are widely used in the world for nearly 20 years because of their high performance, low cost and wide range of uses. Taking Japan as an example, the output of electrolytic capacitor foil was about 3000 tons in 1995. By 2001, the output has reached 70 thousand to 80 thousand tons, almost increasing at an alarming rate.

Send your message to us

Coated aluminum foil for food container FOR 8011

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords