CNBM Tons of Potassium Sulfate (SOP) Project equipments from SOP plant

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tons of Potassium Sulfate Project

General

CNBM is a high-tech enterprises international chemical engineering company, who is pioneering in chemical engineering technologies, and playing a leading role in new technology development, with capability of project consulting, design,procurement, construction management and production guidance. CNBM provide services of chemical engineering and technology, with offering a scope of supply ranging from process design till the supply of completely integrated plants. CNBM master a technology of Potassium Sulfate production line, Calcium Chloride production line,sulfuric acid production line other fertilizers.We have cooperated with many international companies on projects,located Indonesia,Philippines,India,Jordan,Egypt.etc.

Potassium sulfate product quality standard

Potassium sulfate | index | standard | |

| K2O:% | ≥50 | GB20406--2006 | |

| CL-:% | ≤1.0 | ||

| H2SO4:% | ≤0.5 | ||

| H2O:% | ≤1.0 | ||

Mannheim method potassium sulfate production process:

(1) It is a production process with little environmental pollution ;

(2) Mature technology, easy to industrialize production, improved new technologies and new processes, adapt to the requirements of the market economy, enhance the competitiveness of products in the market, the quality of potassium sulfate is good, and the output is high;

Main raw and auxiliary materials supply

| NO | Name | specification | Consumption | Total annual consumption |

| 1 | Potassium chloride | K20≥60% | 830Kg/t | 83,000 tons |

| 2 | sulfuric acid | 98% | 570Kg/t | 57,000 tons |

| 3 | lime | 40Kg/t | 400t |

Introduction to the preparation of potassium sulfate production plant by Mannheim method

Raw material for producing potassium sulfate

The raw material for the preparation of potassium sulfate by the Mannheim method is potassium chloride (KCL) which has K2O ≥ 60% and 98% sulfuric acid.In the production process, the hydrochloric acid system is made into tap water, and the heat required for the reaction is provided by natural gas combustion.

The nature and use of potassium sulfate

K2SO4

Colorless or white crystal or powder, bitter and salty

Melting point: 1069 ° C, soluble in water, insoluble in ethanol, acetone and carbon disulfide, the aqueous solution is slightly acidic.

Uses: 1. Agricultural fertilizer, used in tobacco, fruit trees, sugar cane, potatoes, vegetables, etc.

2, used as a drug (a laxative) and used in the manufacture of alum, glass and potassium carbonate.

Potassium sulfate quality specifications

Appearance: colorless or white crystal or powder.

Industrial synthetic hydrochloric acid

Relative molecular weight: 36.45

Performance: colorless transparent liquid, yellow when there is a small amount of impurities, strong acid is corrosive, can work with a variety of metals.

Uses: Important chemical raw materials for petroleum, metallurgy, printing and dyeing industries, etc.

Basic principle and process flow of potassium sulfate production

A fixed bed metathesis reaction method is employed. The solid potassium chloride and 98% sulfuric acid are continuously added to the reaction chamber at a certain ratio of feed, and the reaction is carried out under the condition of pushing the homogenate at a high temperature above 500 ° C (generally controlled at 500-530 ° C). . The raw material is continuously input under the condition of maintaining the normal bed surface, and the finished potassium sulfate is continuously discharged into the finished pusher from the outlet of the reaction chamber (symmetric two places), and enters the finished product through the gas seal conveyor under the action of cooling and stirring and pulverizing. The belt machine is then lifted, crushed, and finished with a scraper into the finished silo. The hydrogen chloride gas generated in the reaction is absorbed into water to prepare a hydrochloric acid and charged into a storage tank. Exhaust gas is discharged into the atmosphere in accordance with national emission standards.

H2SO4+2KCL →K2 SO4+2HCL-Q

H2SO4 → SO3+H2O-Q

HCL+H2O → HCL·H2O(HCl)+Q

SO3+H2O → H2SO4+Q

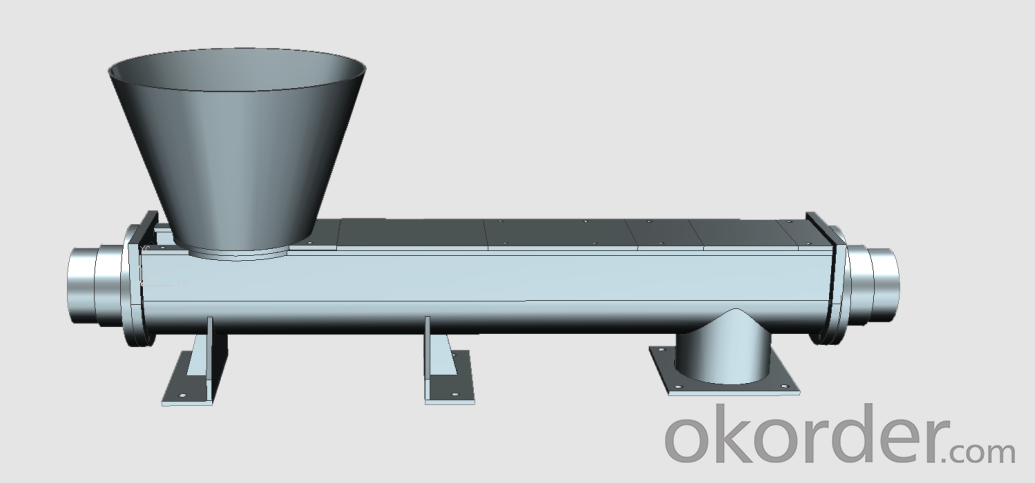

Production equipment overview

Potassium sulfate reactor

The reaction furnace is mainly composed of a combustion chamber (upper) reaction chamber (middle) flue chamber (lower part), and is equipped with a feeding and mechanical stirring pushing device. The core device of the Mannheim method is the reaction furnace. The purity of the product, the conversion rate, the production capacity and the difficulty of operation are all related to the reaction furnace. Therefore, reactor performance is the key to the process. The reaction furnace is mainly made up of a variety of special refractory materials. It has two cavities. The middle elliptical cavity is the reaction chamber. The chamber is equipped with stirring tweezers. When the reaction, the tweezers rotate at 1.1r/min, and the materials are continuously mixed and gradually. Push around the cavity. The upper cavity of the reaction furnace is a combustion chamber, and the combustion chamber has a burner, and the heat released by the fuel indirectly heats the reaction chamber.

Overview of the auxiliary equipment of the reactor system

1. The main machine (with large reducer and motor driven spindle) provides the effect of fabric, mixing and product removal.

2.Reheater: φ1000×4600, cold air and flue gas heat exchange, to preheat the air, reduce the heat loss in the furnace.

3.Potassium sulphate finished product pusher: The pusher barrel is accompanied by a cooling jacket, which functions as cooling, crushing and transfer of the finished product (n≈5.53r/min).

4.Gas-sealed screw conveyor: the function of finished product conveying and gas sealing.

5.Finished belt conveyor: The finished product is conveyed with cooling (with magnets - prevent the iron from entering the rear equipment).

6.Finished bucket elevator: finished product delivery.

7.Finished squeegee conveyor: The finished product is conveyed with cooling jacket.

8.Dust collection bucket, dust collection fan, distributor: collect the finished dust back to the silo.

9. Carbon cooler: After the hydrogen chloride gas at the outlet of the reaction chamber is cooled by the heat exchange, the temperature is lowered to about 50 ° C, and sent to a sulfuric acid gas scrubber.

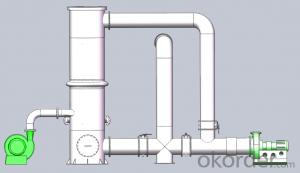

Hydrochloric acid preparation, hydrogen chloride tail gas recovery and circulating water system

1. Sulfuric acid gas scrubber (with circulating acid pump, tank): packed tower, which absorbs trace SO3 and part of hydrogen chloride in the hydrogen chloride mixed gas from carbon cooler to ensure the quality of genuine hydrochloric acid (A acid), and The acid pump outlet sends out a portion of the mixed acid to the carbon cooler to wash a trace of dust from the gas in the reaction chamber to ensure the smoothness and cooling of the carbon cooler. The mixed acid (B acid) controls a certain B e0 to be sent to the B acid intermediate tank.

2. Hydrochloric acid absorption tower (falling film absorption tower) A: The falling acid absorption method (gas-liquid downstream) outlet acid control 18-19Be0 is sent to the intermediate tank of hydrochloric acid, and the three columns of hydrochloric acid absorption tower A are connected in parallel.

3. Hydrochloric acid absorption tower B: packed tower, gas-liquid countercurrent, acid solution enters hydrochloric acid absorption tower A, and hydrogen chloride tail gas is introduced into tail gas recovery tower through hydrogen chloride induced draft fan. The hydrochloric acid absorption tower B is connected in parallel in three.

4. Dilute acid high level tank: Provides a dilute acid solution for acid production at a stable liquid level. The dilute acid solution is from the 3# tail gas recovery tower and is cooled by a dilute acid cooler to enter a dilute acid high level tank.

5. Hydrogen chloride tail gas recovery tower: (with circulating acid pump) packed four-column series (No. 3 → No. 6) gas-liquid countercurrent, the hydrogen chloride tail gas is basically absorbed after acid production. The tail gas is sequentially taken into the No. 3 → No. 6 exhaust gas recovery tower by the HCL exhaust fan and then discharged into the atmosphere (the exhaust gas emission complies with the national exhaust emission standard). The liquid phase flow is No. 6 → No. 5 → No. 4 → No. 3, No. 3 tower The higher concentration of dilute hydrochloric acid is sent to the sulfuric acid gas scrubber.

6. Hydrogen chloride tail gas exhaust fan: The hydrogen chloride gas is pumped in from the reaction chamber to the national atmospheric emission standard GB16297-1996, and discharged into the atmosphere through the exhaust gas chimney to maintain the micro-negative pressure in the reaction chamber to maintain the normal production of potassium sulfate.

7. Target fan: The hydrogen chloride gas is pumped into the process from the furnace door, and after being absorbed by the environmental protection tower, the exhaust gas chimney is discharged into the atmosphere.

8. Intermediate tank of hydrochloric acid (A, B acid): a total of four, a single tank volume of about 12 cubic meters (horizontal). It has the function of intermediate storage and transfer of hydrochloric acid.

- Q: would you crank out some dollars?

- 100 dollar bills. you betcha. here have a 100 and keep the change.

- Q: please hurry school project due TODAY

- Big giant coal burning factories with smoke stacks.

- Q: Communist/Socialist. Like the old Europe stuff. I have looked through the coat of arms for those countries and they all depict something having to do with work I suppose. I mean like farming tools, nuclear power plants, factories, electric poles, telephone towers, telegram lines, and so on.I mean like I think its interesting.

- Communism usually aims to appeal to the working class, and so logos often depict items relevant to that area of society.

- Q: Name some modern machinery/ technology that allows farmers to create bigger farms.?

- tractors sprinklers

- Q: Bally Manufacturing sent Intel Corporation an invoice for machinery with a $24,800 list price. Bally dated the invoice July 23 with 5/10 EOM terms. Intel receives a 40% trade discount. On August 1, Intel Corporation returns $300 of the machinery due to defects. Intel pays the invoice on August 16. What does Intel pay Bally on August 16? The payment on August 16 is $____________

- 14700.00 working notes: 24800-300(return)-40% trade discount =$14700.00 company was not entitled for any cash discount as they are paying invoice on 16th of august and the term was 5/10 meaning the last day to get the discount is 10th of august. I hope my answer is correct.

- Q: Okay, so I'm looking through my bio textbook (not ap) and I come across this graphic about the HIV virus. There's a strip of text that talks about how the virus replicates itself:HIV is equipped with the enzyme reverse transcriptase.........Using the cell's **gene translation machinery**, this DNA then directs the production of thousands of viruses.The thing inside the **s . What is it? Cells don't have machinery! Why does the book call it translation machinery?

- It's talking about the complement of proteins used to copy the DNA and produce new viruses that are hijacked by the virus. Proteins are like little machines. They're the molecules that do everything in the cell.

- Q: humanity have acknowledge all inventions from lighter to x-rays and to infrared, and to ultraviolet rays,electromagnetic propulsions and space travel -seems to provide great assistance to humanity-yet, cancer, AIDS, parkinsons,alzhimers have no cure at all??,global warming,wars etc.. so is science missing A LOT from REALITY??

- Sixty years ago the brand-new technological 'gee-whiz' gadget was television. And it was universally acknowledged that it would be probably the greatest advancement in education since the printed book. So go watch 'South Park', 'MTV', 'SNL', and a few dozen other mindless sitcoms and ask yourself, What went wrong? People tend to get the kind of Government that they deserve. Henry David Thoreau Doug

- Q: hoew do you start a waste paper recycling plant ? what are the machineries required?

- the fee could rely on how large the plant replaced into. you are going to be able to desire to start with a bypass decrease paper shredder and a 5 gallon (19 liter) bucket and a water faucet. So it would desire to fee everywhere from approximately $one hundred to $a million.5 Billion, i assume. additionally the earnings could rely on the size and performance of the plant and the quantity and fee of hard paintings required.

- Q: Hi,My company produces industrial machinery, which for the purposes of this can best be described as a range of different size metal boxes with internal fittings. Currently, we make these from aluminium extrusion and steel infill panels. I'm looking to redesign.Does anyone have suggestions for alternative component systems which provide reasonably strong structures, while being assembled without welding and do not require painting? I've looked at aluminium composite panels and GRP.ThanksS

- Have you considered manufacturing the enclosures from galvanized sheet metal, which can be fabricated into weather resistant enclosures using a metal brake and pop rivets?

- Q: Machinery poll: Exactly what job does a piledriver accomplish?

- It makes your teeth chatter you won't want sex for 2 weeks afterwards. Not recommended for the sensitive lady parts.

Send your message to us

CNBM Tons of Potassium Sulfate (SOP) Project equipments from SOP plant

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords