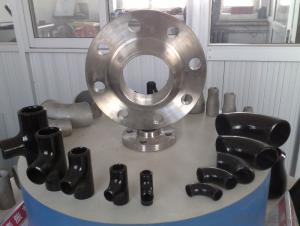

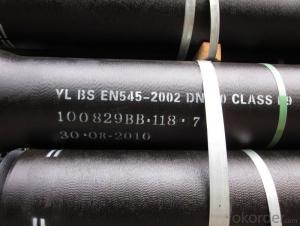

CNBM ISO2531/EN545 DI PIPE & FITTINGS,HIGH QUATITY

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Ductile Iron pipe Fittings:

1.Material Iron ,made in China

2.Technics Casting

3.Model Number DN80-DN2000

4.Brand Name CMAX

CNBM manufactures Ductile Iron Push-on Joint & Mechanical Joint Fittings which conform to Product standards: EN 545:2002, ISO-2531:1998, ANSI/AWWA C153/C110 & GB13295. The fittings are made with the most modern casting technique known as Vacuum Lost Foam Process.

Ductile Iron fittings without branches conform to class-K12. Ductile Iron fittings with branches conform to class-K14. For calculating thickness e= K(0.5 + 0.00IDN).

Some Fabricated Fittings are also available from us

1. Composition of raw material:

l C: 3.4 - 3.7%

l Si: 2.0 - 2.4%

l P: ≤0.08%

l S: ≤0.015%

l Mg: 0.03 - 0.08%

l Mn: ≤0.30%

Average Density of Metal is approximate 7050kg/m

2. Mechanical Properties of ductile iron pipe fittings

Item | Tensile Strength N/mm2 | Elongation % | Proof Stress N/mm2 | Hardness HB | ||

DN80 to DN2000 | DN80 to DN1000 | DN1100 to DN2000 | DN80 to DN1000 | DN1100 to DN2000 | ||

Fittings | ≥420 | ≥5 | ≥300 | ≤230 | ||

3. Works Test Pressure of ductile iron pipe fittings

DN | Minimum hydraulic test pressure (bar) |

Fittings | |

60 to 300 | 25 |

350 to 600 | 16 |

700 to 1000 | 10 |

1100 to 2000 | 10 |

5. Internal Lining

Fittings | |

Standard Coatings | Cement mortar |

Reinforced protections | Epoxy Resin/Epoxy Powder |

Special coatings | Please consult us |

6. External Coatings

Fittings | |

Standard Coatings | Basic protection |

Zinc rich paint + Bituminous paint | |

Reinforced protections | Basic protection + |

Epoxy Resin/Epoxy Powder | |

Special coatings | Please consult us |

- Q: How do steel products contribute to the transportation industry?

- Steel products play a crucial role in the transportation industry as they are used extensively in the manufacturing of vehicles, infrastructure, and components. From cars, trucks, and trains to bridges, rails, and roads, steel provides strength, durability, and reliability. It helps in constructing lightweight yet sturdy frames, bodies, and chassis of vehicles, ensuring safety and efficiency. Additionally, steel is used in the production of bearings, gears, axles, and springs, enhancing the performance and functionality of various transportation systems. Overall, steel products contribute significantly to the transportation industry by providing the necessary strength, structural integrity, and reliability required for safe and efficient movement of people and goods.

- Q: What are the different types of surface finishes for steel products?

- There are several types of surface finishes for steel products, including hot-dip galvanizing, electroplating, powder coating, painting, and passivation.

- Q: What are the applications of alloy steel in manufacturing?

- Alloy steel has a wide range of applications in manufacturing due to its exceptional strength, durability, and resistance to corrosion. It is commonly used in the production of various machinery, tools, and equipment such as automotive parts, aircraft components, industrial machinery, and construction materials. Additionally, alloy steel is utilized in the manufacturing of pipelines, oil and gas drilling equipment, and high-pressure vessels. Its versatility and ability to withstand extreme conditions make it a preferred choice in many manufacturing industries.

- Q: What are the properties of corrosion-resistant steel for marine applications?

- Corrosion-resistant steel for marine applications possesses several key properties. Firstly, it has a high resistance to corrosion, which is crucial when exposed to the harsh and corrosive marine environment. Additionally, it offers excellent strength and durability, ensuring long-term performance even in challenging conditions. It is also often designed to withstand pitting, crevice corrosion, and stress corrosion cracking, which are common issues in marine environments. Furthermore, corrosion-resistant steel for marine applications usually has good weldability, allowing for easy fabrication and maintenance. Overall, these properties make it a reliable and cost-effective choice for various marine structures and equipment.

- Q: What are the different types of steel angles and their applications in construction?

- There are several different types of steel angles used in construction, including equal angles, unequal angles, and L-shaped angles. Equal angles have equal sides and are commonly used to provide structural support, such as in the construction of beams, columns, and frames. They are also used in the fabrication of brackets, reinforcements, and various other structural components. Unequal angles have different sides and are often used to provide additional strength or stability in specific applications. They are commonly utilized in situations where unequal loads or forces need to be supported, such as in the construction of staircases, platforms, and supports for conveyor systems. L-shaped angles, also known as angle irons, have a 90-degree angle and are one of the most versatile types of steel angles. They are frequently used in construction for framing, bracing, and supporting various structures. L-shaped angles are often employed in the construction of shelves, frames for doors and windows, and as reinforcement for concrete structures. Overall, steel angles play a crucial role in construction by providing strength, support, and stability to various structures and components. Their versatility allows for a wide range of applications in different construction projects.

- Q: What are the properties of galvanized steel for outdoor applications?

- Galvanized steel is highly suitable for outdoor applications due to its exceptional properties. It possesses a protective zinc coating that prevents corrosion and rusting, ensuring durability and longevity even in harsh weather conditions. Additionally, galvanized steel exhibits excellent resistance against damage from UV rays, moisture, and various environmental factors, making it ideal for outdoor structures, fences, roofing, and other applications requiring reliable and long-lasting performance.

- Q: What are the advantages of using steel in the manufacturing of playground equipment?

- There are several advantages of using steel in the manufacturing of playground equipment. Firstly, steel is highly durable and can withstand heavy use and extreme weather conditions, making it ideal for playgrounds that are exposed to constant wear and tear. Additionally, steel is rust-resistant, which ensures the longevity and safety of the equipment. Furthermore, steel allows for versatile and intricate designs, allowing manufacturers to create a wide range of engaging and stimulating playground structures. Lastly, steel is a sustainable and environmentally-friendly material as it can be recycled, reducing the impact on natural resources.

- Q: What are the properties of abrasion-resistant steel for industrial equipment?

- Abrasion-resistant steel for industrial equipment possesses several key properties. Firstly, it has excellent hardness, making it resistant to wear and tear caused by constant friction and impact. Additionally, it exhibits high strength, enabling it to withstand heavy loads and extreme conditions. This type of steel also has exceptional toughness, allowing it to endure harsh environments without cracking or breaking. Furthermore, it possesses good weldability, facilitating easy fabrication and maintenance. Overall, abrasion-resistant steel ensures prolonged equipment lifespan, reduced downtime, and increased productivity in industrial settings.

- Q: What are the main factors to consider when selecting steel products for a specific application?

- When selecting steel products for a specific application, there are several key factors to consider. Firstly, the intended use and the specific requirements of the application should be carefully evaluated. This includes factors such as load-bearing capacity, corrosion resistance, and temperature resistance. Secondly, the properties of the steel, such as its strength, ductility, and hardness, need to be considered in relation to the application's demands. Additionally, the cost and availability of the steel should be considered, as well as any relevant industry standards and regulations. Lastly, factors like the required fabrication processes, surface finish, and aesthetics may also play a role in the selection process. Overall, a thorough assessment of these factors will help ensure that the chosen steel product is suitable for the intended application.

- Q: What are the different types of steel forgings and castings available?

- There are several types of steel forgings and castings available, including carbon steel forgings, stainless steel forgings, alloy steel forgings, and ductile iron castings. These materials offer varying degrees of strength, corrosion resistance, and durability, making them suitable for different applications in industries such as automotive, aerospace, and construction.

Send your message to us

CNBM ISO2531/EN545 DI PIPE & FITTINGS,HIGH QUATITY

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords