Plastic Sheets - Closed Cell Vinyl Foam for Good Quality and Price

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 700 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

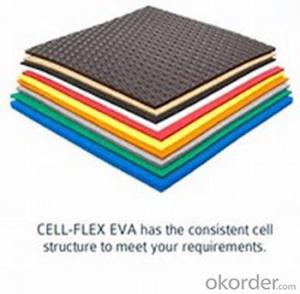

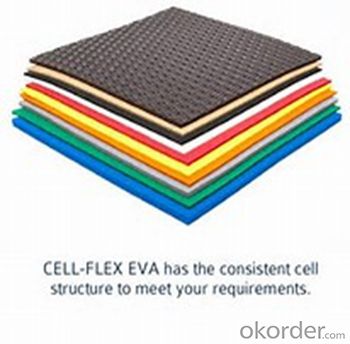

closed cell vinyl foam for good quality and price

Product Introduction

1.PVC foam board is made from polyvinyl chloride, with flat plate surface; it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

2.PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof, anticorrosive, metabolic and recyclable, moisture resistant, lightweight.

Description

PVC Crust Foam Board is easy to clean and maintain, a good deep-drawing quality, light weight, but strong. PVC Foam Board is organic and inorganic combination of the preparation through the series of advanced technologies, the extrusion foam molding, a wood-plastic sheet, extrusions, bar. As the use of the raw materials and production processes do not use glue bonding, no formaldehyde, benzene, ammonia, trichloroethylene, and other harmful substances. And has anti-UV, coloring good performance, heat insulation, noise, acid and alkali resistance, insulation, fire-retardant, anti-corrosion, anti-mildew and anti- pest, moisture resistance, sawing, planing, nails, a good machining performance, and 100% recovery, is a jewel instead of the traditional green timber new material. Compared to PVC free foam board, PVC crust foam board has the better advantages on hardness , cleaning, strength and so on.

Features

1. Feather light, non-absorb water, fire retardant and self-extinguishing

2. Foam Board is sound insulation, heat insulation, noise absorption, heat preservation and corrosion prevention.

3. Weather proof, vandal proof, and can be shaped, moulded, painted and screen printed.

4. Non-warping and stain proof.

5. Non-corrosive, non-toxic and chemical resistant.

6. Tough, rigid with a high impact stregth.

7. PVC Crust Foam Board is easy to clean and maintain.

Application

1.Advertisement: exhibition & display, digital printing, silk screen printing, engraving materials, sign board, etc.

2.Furnitureoffice furniture, cabinet, bath cabinet, etc.

3.Finishing Materialdecorative sheets, storage racks, room segments, etc.

4.Industrial Application: thermoforming products, refrigeratory warehouse project, environmental protection.

| tem | High density pvc foam sheet, die cut advertising sign board |

| Material | PVC foam board |

| Finish | Glossy & Matt |

| Application | Tradeshow, display, promotion, advertising |

| Max printing size | 1220mm ( Width ) x 2440mm ( Length ) |

| MOQ | 50pcs |

| Sample time | 1-3 days |

| Delivery time | 7-10 days and depend on quantity |

| Payment terms | 1. TT, 30% in advance, the balance before shipment |

| 2. Western Union, Paypal, L/C |

- Q: Are plastic sheets resistant to cracking from impact?

- Yes, plastic sheets are generally resistant to cracking from impact.

- Q: Are plastic sheets food safe?

- Yes, plastic sheets can be food safe depending on the specific type of plastic used. Certain food-grade plastics, such as those that meet FDA regulations, are designed to be safe for contact with food and are commonly used in food packaging and preparation. However, it is important to ensure that the plastic sheets you are using are specifically labeled as food safe to guarantee their suitability for storing or handling food.

- Q: How should the plastic cutting boards be cleaned?

- Disinfection method: ginger block for a long time, will produce a strange smell. With ginger or raw onion chopping will wipe it again, then side with boiling water washed, side brush, smell will disappear.

- Q: its see through and comes in different colorsdavid bromstad was using it in his show

- It is a plexiglass. Sold in glass places or where ever glass is sold. I ve never seen it ( the thickness they show) in Home depot and such places.. GL

- Q: Im being OCD but i just bought a 3ds and put my finger under the plastic of the star, home select button thinking it was covered but a plastic packaging sheet.Was i scratching and something i shouldnt have or should it come off?

- i don't remember anything on the 3ds being covered with any plastic but i got it back around christmas so maybe the packaging has changed.

- Q: Are plastic sheets resistant to warping or sagging under heavy loads?

- Yes, plastic sheets are generally resistant to warping or sagging under heavy loads. They have good structural integrity and can withstand significant pressure without deforming. However, the specific type and thickness of the plastic sheet will determine its load-bearing capacity and resistance to warping or sagging.

- Q: Can plastic sheets be used for insulation in refrigeration?

- Yes, plastic sheets can be used for insulation in refrigeration. They provide a barrier between the cold and warm areas, reducing heat transfer and improving energy efficiency. However, it is important to use plastic sheets specifically designed for insulation purposes to ensure optimal performance.

- Q: Talk fast now.

- He'd know the truth by looking at me.

- Q: Are plastic sheets resistant to UV radiation?

- Yes, plastic sheets can be resistant to UV radiation depending on the specific type of plastic used. Some plastics, such as polycarbonate and acrylic, are formulated to have high UV resistance. However, not all plastics offer the same level of UV protection, so it is important to choose the appropriate plastic sheeting for the desired application.

- Q: how big of a roll of sheeting will i need?

- 10' by 10' would cover the bed and sides. Just buy a roll of lightweight Visqueen at the building center. It usually comes in 25' rolls 10 feet wide and you can cut off what you need. You will be able to use the rest of it for other drop cloths and it is a handy thing to keep around the house for emergencies anyway.

Send your message to us

Plastic Sheets - Closed Cell Vinyl Foam for Good Quality and Price

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 700 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords