Plastic Pipe Fittings UK - China PP-R Eblow Watering Irrigation for Industrial Fields

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

The comprehensive technical performance and economic indicator of PP-R are much better than galvanized pipe, UPVC pipe, polyethylene-aluminum compound pipe, PE-X (cross-linked polyethylene) and polybutylene pipe etc. For this reason PP-R is the leading products and widely used for feed-water piping in developed countries in Europe and America.

Nowadays PPR pipes win more attention and have been used all over the whole world more widely with its excellent sanitization performance, high heat resistance, compression resistance, corrosion resistance, pliability and seismic performance which make PP-R the real environmental friendly pipe

Applications of PPR Pipe (white, gray):

1) Cold and hot water supply systems for civil and industrial constructions, e.g. in residential buildings, hospitals, hotels, school and office buildings, ship building

2) Drinking water systems and food industry pipe works

3) Central air conditioning system

4) Irrigating system for gardens and green houses

5) Public and sport facilities such as swimming pools and stadiums

6) For rainwater utilization systems.

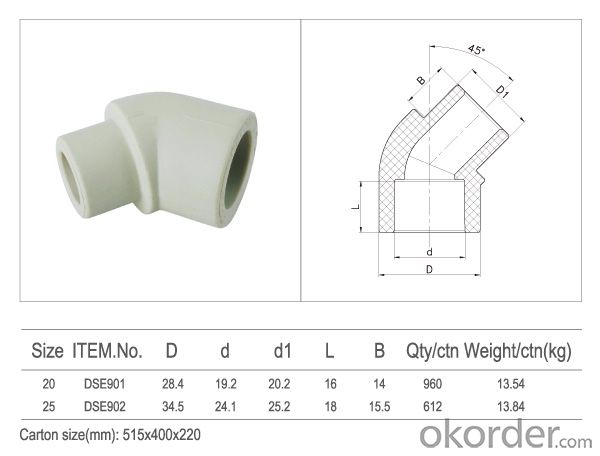

Product Description

Product Show

Our Services

1. OEM Manufacturing welcome: Product, Package...

2. Sample order

3. We will reply you for your inquiry in 24 hours.

4. after sending, we will track the products for you once every two days, until you get the products. When you got the

goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer

the solve way for you.

- Q: Are plastic pipe fittings suitable for industrial cooling towers?

- Yes, plastic pipe fittings are suitable for industrial cooling towers. Plastic fittings are commonly used in cooling tower systems due to their corrosion resistance, durability, and cost-effectiveness. They can effectively handle the high flow rates and temperature variations often associated with industrial cooling tower applications. Additionally, plastic fittings are lightweight and easy to install, making them a preferred choice for many cooling tower installations.

- Q: Are plastic pipe fittings more affordable than metal pipe fittings?

- Yes, plastic pipe fittings are generally more affordable than metal pipe fittings.

- Q: Indoor plastic water supply pipe, 20 of the 20 refers to the inside diameter or outside diameter?

- The composite pipe is typical of aluminum plastic tube, but it has been phased out because of its thermal expansion and cold contractionPlastic pipe is the most commonly used PPR water pipe, safe, non-toxic, convenient installation, low prices and many other reasons, making it the most commonly used water pipes in home improvement. But because of environmental hormones, more and more people began to use metal tubes or PPR lined metal pipes as water supply pipelines.

- Q: Can plastic pipe fittings be used for sewage systems?

- Yes, plastic pipe fittings can be used for sewage systems. Plastic materials such as PVC (polyvinyl chloride) and ABS (acrylonitrile butadiene styrene) are commonly used in sewage systems due to their durability, corrosion resistance, and cost-effectiveness. These fittings are designed to handle the demands of sewage transport and are widely accepted in the plumbing industry for sewage applications.

- Q: Can plastic pipe fittings be used for chemical storage tanks?

- No, plastic pipe fittings are not suitable for chemical storage tanks as they may not have the necessary chemical resistance and structural integrity required to safely store chemicals.

- Q: Can plastic pipe fittings be used for wastewater disinfection systems?

- No, plastic pipe fittings are not suitable for wastewater disinfection systems. These systems require materials that can withstand harsh chemicals and high temperatures, which plastic fittings may not be able to handle.

- Q: Can plastic pipe fittings be used for landfill leachate collection?

- Yes, plastic pipe fittings can be used for landfill leachate collection. Plastic pipes and fittings are commonly used in landfill leachate collection systems due to their durability, resistance to corrosion, and ability to withstand harsh environments. They provide a cost-effective solution for effectively collecting and transporting leachate from landfills.

- Q: Can plastic pipe fittings be used for elevated water storage systems?

- Yes, plastic pipe fittings can be used for elevated water storage systems. Plastic pipe fittings are commonly used in plumbing systems and can withstand the pressure and load of elevated water storage. They are lightweight, durable, and resistant to corrosion, making them suitable for such applications. However, it is important to ensure that the fittings are designed and rated for the specific requirements of the elevated water storage system.

- Q: Are plastic pipe fittings resistant to impact and pressure?

- Yes, plastic pipe fittings are generally resistant to impact and pressure. They are designed to withstand the forces exerted on them during normal operating conditions, ensuring durability and reliability in various applications. However, the specific resistance may vary depending on the type and quality of the plastic used in the fittings.

- Q: Can plastic pipe fittings be used for chemical dosing in water treatment?

- Yes, plastic pipe fittings can be used for chemical dosing in water treatment. Plastic pipe fittings are commonly used in water treatment processes due to their resistance to corrosion, durability, and affordability. They are suitable for handling a variety of chemicals used for dosing in water treatment, such as chlorine, coagulants, flocculants, and pH adjusters. However, it is important to select the appropriate type of plastic pipe fittings that are compatible with the specific chemicals being dosed to ensure safe and efficient water treatment operations.

Send your message to us

Plastic Pipe Fittings UK - China PP-R Eblow Watering Irrigation for Industrial Fields

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords