Anodized Aluminum Strips for Certain Structural Retrofit Building Applications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Advertisement: display platforms, signboards, fascia, shop fronts...

(2).Exterior: wall cladding, facades, roofing, canopies, renovations...

(3).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

3. Feature of Aluminum

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

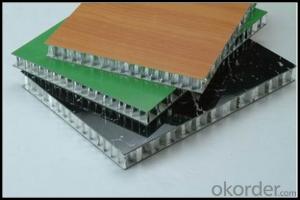

4. Image of Aluminum

5. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

6. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: Aluminium belt car

- Automobiles are machines of high speed. In order to give their performance the best, people prefer to improve their roads to adapt to cars rather than re - adapt them to bad roads. Now some people are interested in track cars, keen on retro, playing games and satisfying personal needs. 3 、 tracks are now used on slow tractors and tanks. In order to improve the speed of the military, or the use of wheeled armored personnel carriers.

- Q: Is it good to drive a wheeled excavator or an aluminum belt?

- How many people do you say you drive, or do you drive more tanks? However, the western development is over, the excavator is not fragrant. Go to the second-hand Internet to see the excavator is very cheap. Take mine. Thank you。。。

- Q: Are aluminum strips suitable for manufacturing automotive components?

- <p>Yes, aluminum strips are commonly used for automotive parts due to their lightweight, high strength, and corrosion resistance. They are utilized in various components such as engine parts, body panels, and suspension systems to reduce weight and improve fuel efficiency. Additionally, aluminum's recyclability makes it an environmentally friendly choice for the automotive industry.</p>

- Q: This question asks for guidance on selecting the appropriate aluminum strip for home use.

- <p>To choose the right type of aluminum strip for your home, consider the following factors: 1) Purpose: Determine if the strip is for decoration, structural support, or insulation. 2) Thickness: Select the appropriate thickness based on the strip's purpose and load-bearing requirements. 3) Finish: Choose between anodized, painted, or brushed finishes based on your aesthetic preferences and durability needs. 4) Width and Length: Ensure the strip's dimensions match your project specifications. 5) Quality: Opt for high-quality aluminum to ensure longevity and resistance to corrosion. 6) Compatibility: Ensure the strip is compatible with other materials in your home. Consult with a professional or supplier for personalized advice based on your specific needs.</p>

- Q: Is it possible to utilize aluminum strips in constructing a rainscreen wall system?

- <p>Yes, aluminum strips can be used to create a rainscreen wall system. Aluminum is a popular choice due to its durability, resistance to corrosion, and low maintenance requirements. It allows for proper ventilation and drainage behind the cladding, which helps prevent moisture damage and thermal stress. When designing a rainscreen system with aluminum strips, ensure that the installation follows building codes and standards, and that the strips are properly spaced and sealed to maintain the system's effectiveness.</p>

- Q: Is it possible to use aluminum strips to construct a solar reflector system for residential or commercial purposes?

- <p>Yes, you can use aluminum strips to create a solar reflector system for your home or business. Aluminum is a reflective material and can be shaped into strips to reflect sunlight. These strips can be arranged in a way to direct sunlight towards solar panels or into specific areas to reduce the need for artificial lighting and heating. However, for optimal efficiency, you should consider the angle of reflection, the positioning of the strips relative to the sun's path, and the overall design of the system. Consulting with a professional in solar technology can help ensure that your solar reflector system is effective and safe.</p>

- Q: Is it possible to utilize aluminum strips as a material for insulating interior walls?

- <p>Aluminum strips are not typically used for interior wall insulation. Insulation materials are designed to provide thermal resistance, and aluminum is a good conductor of heat, which makes it unsuitable for insulation purposes. Common insulation materials include fiberglass, mineral wool, and polyurethane foam, which are effective at reducing heat transfer. Aluminum strips might be used in construction for other purposes, such as reinforcement or as a vapor barrier, but not for insulation.</p>

- Q: This question asks about potential hazards or issues that might arise from using aluminum strips as flooring material.

- <p>Safety concerns related to using aluminum strips for flooring include potential slip hazards, especially in wet conditions, due to the smooth surface of aluminum. There's also a risk of electrocution if the aluminum comes into contact with electrical wiring or outlets. Additionally, aluminum can conduct heat and cold, making the floor uncomfortable underfoot in extreme temperatures. The material may also dent or scratch easily, posing a tripping hazard. Lastly, concerns about the long-term health effects of aluminum exposure, though not fully proven, should be considered.</p>

- Q: This question asks about the durability and strength of aluminum strips for outdoor applications.

- <p>Aluminum strips are indeed strong enough for exterior use. They are lightweight, corrosion-resistant, and have high tensile strength, making them suitable for various outdoor applications such as siding, roofing, and fencing. Their resistance to weathering and low maintenance requirements add to their popularity in exterior settings. However, the specific strength and durability can vary based on the alloy composition and thickness of the strips, so it's important to select the appropriate grade of aluminum for the intended use.</p>

- Q: This question asks about the differences between aluminum and stainless steel in terms of their ability to resist corrosion.

- <p>Yes, there are differences between aluminum and stainless steel in terms of corrosion resistance. Aluminum is highly resistant to corrosion due to the formation of a protective oxide layer on its surface, which prevents further oxidation. This makes it suitable for environments with high moisture or exposure to corrosive substances. Stainless steel, on the other hand, also has good corrosion resistance, especially when it contains higher amounts of chromium, which forms a passive film that protects the metal from corrosion. However, stainless steel can be more susceptible to corrosion in certain environments, such as those with chlorides, compared to aluminum.</p>

Send your message to us

Anodized Aluminum Strips for Certain Structural Retrofit Building Applications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords