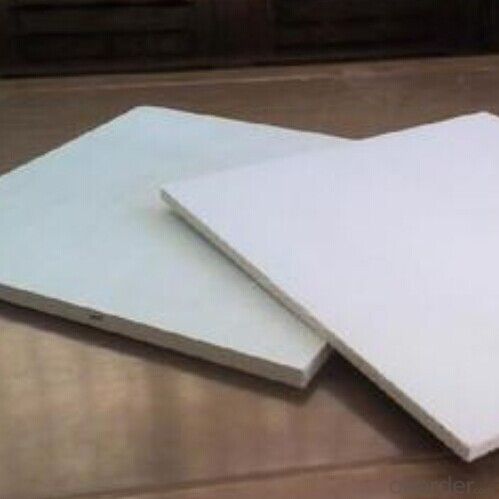

CE Approved Magnesium Oxide Board top quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

DESCRIPTION

Magnesium oxide board is made from Magnesium Oxide(MgO), Magnesium Chloride(Mgcl2), fiberglass mesh, sawdust, perlite etc.,using highly purified active MgO as the main fireproof material of board, high-quality MgCl2 as the main cementing material to solidify other materials, alkali-resistance fiberglass mesh to ensure the high strength of board, soft sawdust and light non-combustible perlite as filling materials. It is a kind of Eco-friendly fireproof board widely used in construction and decoration.

(Pave slurry on the surface of MGO board to reduce the holes, make the surface more smoothness and less holes. Slurry paved board is a kind building material to further process.Suit to stick thin decorative material or paint on the board.)

APPLICATION

Partition and ceiling in the room, office building, hotel, hospital, airport, subway, gymnasium, library, museum, theater, factory building, computer laboratory, indoor natatorium. It is also used as the backing-lining, fireproof door and other wallboard, outdoor bill-board; base plate of various kinds of plaques; outside board of the ventilation shaft and the steel construction; roof boarding; electric wire and cable wraps up and applies etc.

FEATURE

1. Fireproof

It was tested by the National Center for Quality Supervision and Testing of Fire Building Materials (NFTC). Its fireproof level is rated level A (nonflammable level)

2. Dam proof

It is excellent in moisture-resistance. Dry bending strength is 15Mpa. Bending strength under absorbed moisture is 22Mpa.

3. Heat insulation

It has heat prevention material incorporated, it has great feature of heat prevention. Thermal resistance is 1.14m2k/w.

4. Soundproof

It is proved to have good noise insulation property after inspected by the National Center for Quality Supervision and Testing of Fire Building Materials (NFTC), The noise insulation factor of the wall can reach 44dB and 47dB. It has the best noise insulation constitution in China, especially the 95mm wall comprised by the 10mm board.It is light, it can save time, space, weight and expense. It is a new and high efficient wall.

5. Compact resistance

It is a light board. Its density is less than 1.0×1.03kg/m3. At the same time its bending strength and impact resistance is excellent. Also, it will maintain its' quality during construction.

SPECIFICATION

1. Size: 1200*2400mm 1220*2440mm 1200*3000mm

2. Thickness: 3mm to 20mm

3. Notes:other specifications is available.

TECHNICAL DATA

Density | 0.95g/cm³ |

Bending strength | 19.5MPa |

Typical moisture content | 6% |

Drying shrinkage | 0.26% |

Moisture movement | 0.50% |

Impact strength | 6.2KJ/m² |

Pull put force of Screw | 37.1N/mm |

Non combustible performance | According to GB8624-1997, Combustibility is A1 Class. |

Fire rating limited | 6mm:>2Hours; 12mm:>4Hours; |

Thermal Coefficient | 0.109W/(m.k) |

- Q: 8K mirror plate how clean

- Mirror stainless steel surface super clear light, 3 meters can clearly reflect the characters image, with the mirror is very similar, wide range of uses, but its cleaning operation technology is very elegant, we should pay attention to the process of cleaning to prevent the use of hard and corrosive materials to do cleaning ( Such as: blade, scouring pad, dirty rag, oil curing agent, alkaline, acidic), 1. In a place where there is a stain, a small amount of banana water can be used to eradicate stains. 2. Use a solution that has been diluted with sewage and rinse the surface of the mirror with a rag. 3. Re-use clean water, with a rag to have cleaned the mirror stainless steel scrub clean (be sure to dry the water stains Oh, otherwise there will be ugly water stains). 4. Equal mirror stainless steel appearance dry, with a stainless steel oil wiping the stainless steel for the smooth and broken lines and wiping until the stainless steel surface evenly modified stainless steel oil, color uniformity, at the moment can be used in the fingers of stainless steel contact, Traces of stainless steel glazing maintenance end. This work to stop the use of hard things to clean, only with a soft wipe operation

- Q: Is the transparent sheet of the material the cheapest?

- PPC board with it, the price is not expensive, the most important quality is very good

- Q: Which master please teach about aluminum alloy doors and windows under the material calculation method? Flattened; push-pull can be the best example. Thank you!

- Aluminum alloy cutting can be used plasma cutting machine, high pressure water jet cutting machine and laser cutting machine and other cutting equipment. These three different cutting methods have their own advantages and disadvantages, according to the needs of the product, the use of different equipment to process aluminum alloy raw materials. 1. Plasma cutting Plasma cutting is a high-temperature plasma arc as a heat source, the local melting of the cutting metal, while the use of high-speed air flow will melt the metal blown to form a narrow incision of a process. Hydrogen as a cutting gas, argon as arc gas, nitrogen is vortex gas, cooling the torque of the various components and blown away the molten metal. The advantages of plasma cutting are: processing speed, the plate and large sheet metal processing capacity. But the plasma cutting products need to secondary processing, cutting the arc produced by large, gas smoke toxic, greater environmental pollution.

- Q: The production of melamine sheet

- Melamine board Melamine board, full name is melamine impregnated film paper facing wood-based panel. Is to put the paper with different colors or textures into the melamine resin adhesive soak, and then dry to a certain degree of curing, will be paved in the particleboard, medium density fiberboard or hard fiber board surface, made by hot pressing plate. In the production process, usually by the combination of several layers of paper, the number of depending on the number of purposes. General sub-surface paper, decorative paper, covered paper and the underlying paper and other components. Surface paper, is placed on the top of the decorative plate, from the role of decorative paper, so that after heating and pressing the surface of the plate highly transparent, hard surface hard wear, this paper requires good water absorption, white and clean, transparent after dipping. Decorative paper, that is, wood grain paper, is an important part of decorative panels, with a background or no background, printed on a variety of patterns of decorative paper, placed under the surface paper, mainly from the decorative effect, this layer requires paper Has good hiding power, impregnation and printing performance. Cover paper, also known as titanium white paper, generally in the manufacture of light decorative panels, placed under the decorative paper to prevent the underlying phenolic resin through to the surface, its main role is to cover the surface of the substrate color spots. Therefore, require a good coverage. The above three kinds of paper were soaked with melamine resin. The bottom of the paper, is the decorative board of the base material, the board from the mechanical properties of the role is impregnated with phenolic resin by drying, the production can be used according to the thickness of the plate or to determine a number of layers.

- Q: Does the regular FR4 sheet contain halogen?

- Very likely to contain halogen, but there is a standard, as long as no more than the minimum standards can also meet the European environmental standards.

- Q: Circuit board plate classification, distinction between advantages and disadvantages

- Circuit board plate classification: FR-1: flame retardant copper foil phenolic paper laminate. IPC4101 detailed specification number 02; Tg N / A. FR-4: Flame Retardant Copper Foil Epoxy E Glass Fiber Cloth Laminate and Its Adhesive Sheet Material. IPC4101 detailed specification number 21; Tg ≥ 100 ℃; Flame Retardant Copper Foil Modified or Unmodified Epoxy E Glass Fiber Cloth Laminate and Its Bonded Sheet Material. IPC4101 detailed specification number 24; Tg 150 ° C to 200 ° C; Flame Retardant Copper Foil Epoxy / PPO Glass Cloth Laminate and Its Adhesive Sheet Material. IPC4101 detailed specification number 25; Tg 150 ° C to 200 ° C; Flame Retardant Copper Foil Modified or Unmodified Epoxy Glass Cloth Laminate and Its Bonded Sheet Material. IPC4101 detailed specification number 26; Tg 170 ℃ ~ 220 ℃; Flame Retardant Copper Foil Epoxy E Glass Cloth Laminate (for Catalytic Addition). IPC4101 detailed specification number 82; Tg N / A; 94vo-cem-1. Good and bad distinction: meet the standard for the excellent, do not meet the specifications for the poor.

- Q: What is love board?

- AIG is the Austrian Group of Agrites FRITZ EGGER GMBH Co. is located in 17 factories in Europe, the production of man-made sheet, environmental protection level to the European E1 level. The Aige plate substrate is covered with a layer of special dipping treatment, with anti-characterization, acid and alkali surface, is widely used in plate furniture and kitchen furniture, English referred to as MFC. ??????? The love plate is selected from coniferous trees grown in the continental margin of the European continent. The love grid overcomes the shortcomings of natural wood and has physical properties that are not easily deformed and stable. Ai grid is a kind of natural logs by cutting, crushing, high temperature and pressure made of a more suitable for furniture production and use of the plate.

- Q: Millennium mill plate is good or the new millennium plate is good

- The new millennium ah ~ Millennium boat operator line brand, the brand with the price on the expensive ah But the new millennium count the second line of the brand, although the fame of thousands of years, but the quality is still very good drops, but also e0 level of eco-eco-board, compared to the price also offers! So for me this ordinary people still feel better than the new millennium!

- Q: What is FR4 sheet

- FR-4 is a glass fiber epoxy resin CCL, a circuit board in the substrate, in fact, you should have seen, such as the kind of small game machine to open, inside the green board is FR-4 to do circuit board. FR4FR5 epoxy board by a special electronic cloth impregnated with epoxy phenolic resin and other materials by high temperature and high pressure hot plate made of laminated products. With high mechanical properties and dielectric properties, good insulation properties and heat resistance and moisture resistance, and a good mechanical processing. Application: for electrical and electrical equipment for the insulation structure of parts, also widely used In the PCB test; and can be used in humid environmental conditions and transformer oil.

- Q: What are the types of decorative plates?

- Decorative sheet types are blockboard, plywood, decorative panels, MDF, Glulam, Particleboard, Fireboard, Gypsum board, PVC sheet, Aluminum plate, Aluminum plate, 3D board. Xiaobian today to simply introduce you to Glulam and PVC sheet two common life of the plate. Decorative materials are divided into two parts: part of the outdoor materials, part of the indoor materials. Indoor materials and then divided into stone, sheet, sheet, profile, wire five types. Decorative sheet is the general term for all plates, mainly: blockboard, plywood, decorative panels, MDF, Glulam, Particleboard, Fireboard, Gypsum board, PVC board, Aluminum gusset plate, Aluminum plate,

Send your message to us

CE Approved Magnesium Oxide Board top quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords