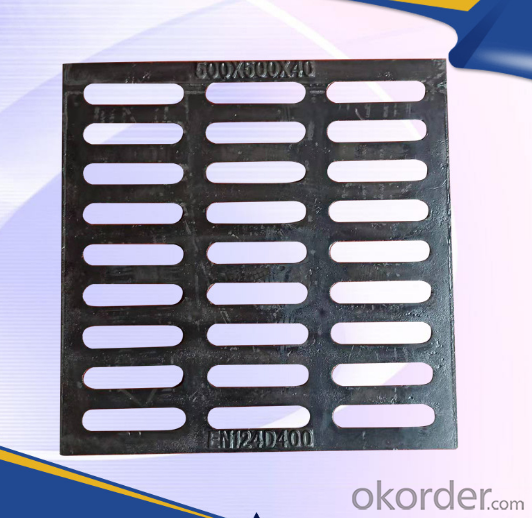

Casted Ductile Iron Manhole Cover C250 for Mining with Frames Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1) production standard: EN124 from A15 to F900

2) Material: grey iron, ductile iron

3) Type:round type and Square type,triangle

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) | Unit Weight (kg/set) |

| RGC-01L | C250 | 390*325 | 530*465 | 100 | 23 |

1.Standard:ISO9001,EN124

2.Applicable medium:gases,liquids,steam

3.Materail:ductile iron,Gray cast iron

Tested item standad

Tensile strength (Mpa)>10

Compressive strength (Mpa)>30

Modulus of elasticity(kg/cm2)>1.4*104

Cold-hot resistance measure<0.4< span="">

Water-absorption<1.0< span="">

Surface treatment

Black bitumen coated and hot gavanized

Advantages

Good compressive, waterproof,anti-rust ,bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% or so lower than other companies.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1.Can I get free samples?

A: Yes, we can provide you the free sample, but you need to bear their own delivery costs.

2.Can I request to change the form of packaging and transportation?

A:Yes,We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

- Q: What's the effect of casting copper?

- Riga. Copper is copper components, promote the graphitization of the copper element, make dense tissue, and to refine and improve the uniform distribution of graphite, which can reduce the chilling tendency of the cast iron, but also can promote the formation of pearlite, has a favorable effect on the section sensitivity. Copper has the tendency to strengthen cast iron, ferrite and pearlite, so it can increase the strength of cast iron. The tensile strength and bending strength of cast iron almost increase with the amount of copper in it, especially in low carbon cast iron.

- Q: The casting defects of pores, trachoma how to repair?

- Airhole above 2mm recommended LT101 casting defect repair agent. If repair quality requirements, high availability LT111 iron repair agent, LT112 steel repair agent, LT113 aluminum repair agent, LT114 copper repair agent.

- Q: our factory now produces steel castings in the use of polishing directly after spraying processing, but the powder sprayed 15But the spray powder touched off what is the reason we are not very strict requirements not only need to peel off bubbles can also, because our products are steel castings so we use steam hole sludge put on. Do not know if this spray treatment has no effect to thank friends with us!

- The pre treatment temperature and the quality of plastic powder are likely to be problems

- Q: What are the requirements for casting steel castings?

- 4 thickness, most should be placed above the.5 and try to reduce the number of.6, the sand core should be used in classification of flat surface

- Q: Explain the heat treatment effect of casting parts, forging parts and welding parts

- Good welding of low carbon steel (alloy), probably because the weld workpiece rigidity, fast cooling, the weld internal crystallization of brittle microstructure (martensite), so after welding or welding process welding using self heat, reasonable arrangement of weld, welding seam and heat affected zone heat treatment. The welding heat treatment is often used to preheat before welding, after welding withasbestos cloth covering slow cooling annealing, reach the purpose, its main function is to reduce the internal stress, improve the weld microstructure of martensite formation, reduce brittle tendency, preventing welding cracks.

- Q: The difference between cement sand castings, resin sand castings and vacuum casting parts

- Our country or international, in all casting production in 60 ~ 70% by sand casting is produced, of which about 70% is used in the production of clay sand. The main reason is that the cost of sand casting is low compared with other casting method, simple production process and short production cycle. So as the car engine cylinder body the cylinder head, crankshaft castings are produced using clay wet sand molding process. When the wet type can not meet the requirement to consider the use of clay sand table dry sand, dry sand mold or other sand.

- Q: As shown, how do I achieve the tightness test of this product, and achieve industrial production? Seek expert advice.

- Precise and tight sealing of the surface to which the test piece is to be tested, equipped with an airtight test instrument, and an electrical control system. You can complete automated testing equipment

- Q: Why should pig iron be used in casting?

- 1, in the absence of special requirements, the most important thing is that the price is cheap.2, pig iron castings quenching process requirements are not high. You can do it by hand.3, pig iron casting hardness is very large, can meet many requirements.4, pig iron castings, high temperature resistance is relatively strong. Like stoves are pig iron castings.5, pig iron casting plasticity is very bad, but in some experiments, but use this weakness to improve the sensitivity of the experiment.Wait

- Q: How to solve casting defect casting?

- Different defects, different solutions, some shortcomings, the current domestic level can not be resolved

- Q: How can the casting be free of trachoma?

- 2, pouring temperature should be enough, otherwise the sand can not float up;

Send your message to us

Casted Ductile Iron Manhole Cover C250 for Mining with Frames Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords