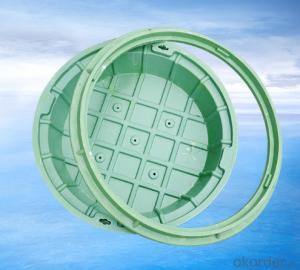

Cast iron Concrete Manhole Covers, Ductile iron Manhole Cover in Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

1) Material

a) Ductile Iron GGG500-7 & 400-12

b) Grey Iron GG20

2) Designs.

a) EN124 A15, B125, C250, D400, E600 and F900

b) A60005 for casting design

c) Major standards designs available

d) As per customers' drawings or samples

3) Process

c) Molding boards

d) Green sand with hand molding

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) | Unit Weight (kg/set) |

| PBC400 | B125 | 300×300 | 400×400 | 30 | 18 |

| PBC500 | B125 | 400×400 | 500×500 | 35 | 17 |

| PBC550 | B125 | 450×450 | 550×550 | 35 | 21 |

Advantages:

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life

(at least 30 years). The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than. Contain no metal and no recovery value, anti-theft.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

Our Services

1. Sample is available for free.

2. OEM and ODM are welcome.

3. Free charge of design labels and cartons.

4. Our products: produced by the hydraulic Press. Meanwhile, a number of experienced workers do the strictly Quality control and have production tracking program.

5. Our price: we are the factory, we provide the most competitive price with good quality, and large order quantity will get big support by us!

6. Professional technical support with free charge.

Delivery Time

30-45 days depends on the demand quantity

FAQ

1. Are you a trader or manufacturer ?

We are professional manufacturer for more than 30 years .Our company products including ductile cast iron rain grate,nodular cast iron manhole covers,ductile iron anti-theft covers,urban greening tree pit cover plate etc.

2. What is your products advantage ?

A.All kinds of size as customer's requirements;

B.Small quantity trial order is welcome

C.Customized design is available and free, Such as Color, Logo, Panel, Load and Dimension etc.

D.Quality control and Promtly delivery

E.Good after sales servic

- Q: Casting blank in the cooling process to release a large amount of heat energy, what can be recycled?

- Casting, do not need to provide a rough casting foundry drawings, according to your chart will put foot margin in the processing needs of the surface, the rest of the size can be found according to the mechanical design manual and manual casting. General Casting Factory Casting Division will be in your chart marked on shrinkage and processing margin figure (usually with red and green pen) to the patternmaker production of wood or other material mould diagram.

- Q: How to calculate the price of casting parts?

- Cost of raw materials + electricity (fuel) costs + workers' wages + managers' wages + transport costs + raw materials burned + accessories costs + equipment maintenance depreciation costs + management fees + tax. The most convenient, the raw material market price plus 2000 yuan, plus you want profits on the line.

- Q: Casting parts need to be subjected to the kind of heat treatment after the weldment is finished

- 1, gray cast iron: General graphite annealing, to be heat treatment annealing, surface hardening etc.; ductile iron can be various: annealing, normalizing, quenching and isothermal quenching, surface treatment, chemical heat treatment.2. Pouring liquid metal into the casting cavity which adapts to the shape of parts. After cooling and solidification, the casting method is called casting. Castings obtained by casting are called castings. Casting structure design: ensure the working performance and mechanical performance requirements, consider the technical requirements and performance of alloy casting casting casting structure, casting structure design is reasonable or not, the casting quality, productivity and cost has a great influence.3. Heat treatment is a metal hot working process in which the material is in solid state by means of heating, heat preservation and cooling to obtain desired microstructure and properties

- Q: What is the difference between forging parts and casting parts?

- The casting parts are low in cost and short in production period. Because the molten iron has good flow properties, complex shapes can be formed. But because there may be sand holes, pores, shrinkage holes and other defects, the quality is unstable, easy to produce many defects, mechanical properties are not forged well, thus affecting the service life.

- Q: What should I pay attention to when designing a casting structure?

- (2) in the prevention of metal mold casting misrun and cold partition should pay attention to the following problems: the structure of A casting thickness should be appropriate not too thin, especially when casting size when not too thin; the B should avoid a big level, because it makes the liquid metal in the casting. Rise slowly, and the air contact surface, easy oxidation, and because the metal type liquid metal heat quickly, quickly lose liquidity, easy to cause misrun and cold lap, slag and other defects; C casting shape should be streamlined to avoid sharp corners and has sharp change connection structure in order to facilitate the flow of liquid metal. 2 in the design of metal castings in a complex shape, if the production process is very difficult, should not affect the casting conditions, try to make the casting has simple shape, strong structure change, removed from metallic die for.

- Q: What are the causes of pitting on the surface of a precision casting?

- The quality of the shell surface is out of order. Or shot blasting out of question.

- Q: Would you please tell me how to use casting parts for a year?The cast of an aircraft wing needs to be put aside for a year before it breaks;Does anyone know why?

- There are various casting stresses after casting, which can be divided into two kinds: thermal stress and shrinkage stress. In a long time placed in the atmosphere, called aging treatment.Aging treatment is an effective measure to eliminate casting stress. Aging is divided into natural aging, thermal aging and resonance aging.1, the so-called natural aging, the casting is placed in the open field for more than half a year, so that the internal stress relief.

- Q: Cause of choking of casting parts

- Choke fire is the process of pouring a large number of gases can not be discharged smoothly, boiling in the metal liquid, resulting in a large number of castings in the pores, and even incomplete casting defects

- Q: Why should pig iron be used in casting?

- Not necessarily is iron, steel, stainless steel, aluminum, copper can be cast iron, is cheaper, and better properties of cast out, for example, is not easy to rust, high strength, easy processing and so on, and is the only iron iron cast out, it is not necessarily the raw pig iron, plus some other material

- Q: How can the casting be free of trachoma?

- 3, the gate is not facing sand core, flush sand core, will cause trachoma.

Send your message to us

Cast iron Concrete Manhole Covers, Ductile iron Manhole Cover in Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords