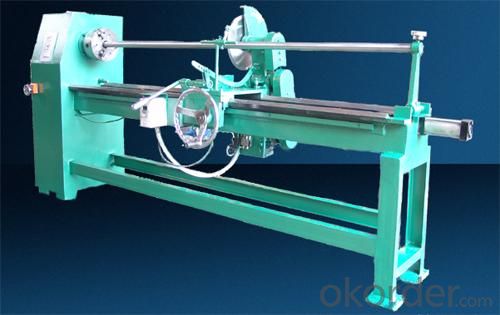

BX-510 High-precision Slitting Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Use:

used for rewinding and slitting of various types of non-adhesive material.

Characterisics :

slitting machine

Left and right spindles are adopted to unreel by centre reeling,the reeling and rewinding adopt pneumatic core shaft,rewinding automatic tensity control,reeling manual tensity control.About the differential device adjustment the tensity is balanced.The splitting shall adopt upper and lower rotary blade. Revolves the work table assistance to unload the volume,while adopting digital control drive system and human-machine interface touch data input model.PLC centralism processing.Electric engine is accommodidated by transducer and running steadily.Receives the reel rocking shaft by the hydraulic pressure actuationrotation,the photoelectric control side;guider roller,the sound of something astir is balanced;processing,the cutting bar,quenching and retempering treatment ,the rotary system puts the volume work table,EPC automatically investigates, this machine minute row volume end surface to the smooth ,easy to operate.

Application :

Maximum valid width of material : 1350mm

Maximum valid diameter of material : 500mm

maximum valid rewinding diameter : 700mm

internal diameter of rewinding paper pipe :3"

slitting tool : upper and lower rotary knives

Maximum width of strip : 1350mm

minimum width of strip : 5mm

the precision of stripping : ±0.1mm

motor power : 8.5kw

the speed of striping : 30m/minute

working voltage :380V 50Hz

the precision of border-entangling: ±0.3mm

- Q: What are the shortcomings of traditional machining?

- Low efficiency, high cost, batch processing, then the processing quality is not stable, the accuracy is not high, labor intensity, processing staff, frequent processing times, and now good equipment to complete the car, drilling, milling and other processes.

- Q: Information on building materials decoration.

- Building Materials Industry Wallpapers Flooring Pallet Handling Machinery Fireproof Materials Waterproof and Moisture Materials Heat Insulation Materials Pipe Fittings Pipe Fittings Concrete and Products Activities Furniture Manufacturing Machinery Building Materials Processing Building Glass Construction Related

- Q: Information on building materials decoration.

- products special building materials ceiling paint culture stone processing machinery brick, tile and block decoration building materials agent operating reference:

- Q: Classification and components of hydraulic press

- According to the control mode classification According to the control mode, the hydraulic equipment can be divided into electronic control, machine control and manual control three categories.

- Q: Mechanical processing technology to mechanical product design, specifically to prepare what?

- Electrical aspects of more understanding to understand, engage in design to consider more problems, and often a project is not a person can get, need is a technical team.

- Q: Main classification of hydraulic machinery?

- (3) according to the degree of precision equipment according to the degree of precision, hydraulic equipment can be divided into precision equipment and general equipment.

- Q: What gear is machined out of the gear?

- Modern is the use of Fan Chengfa, straight or helical gears in the hobbing machine with a gear hob or machining on the gear machine with a tooth cutter, in order to improve gear accuracy, as well as honing and gear grinding machine.

- Q: What is the principle of the cutting order in machining?

- In the arrangement of mechanical cutting process, should be based on the processing stage of the division, the choice of benchmarks and the surface to be processed to decide, generally should follow the following principles:

- Q: What are the aspects of the mechanical processing quality

- Mechanical processing, machine tools, fixtures, knives and workpieces constitute a complete system, known as the process system. The machining error is due to the fact that there are many error factors in the process system before and after processing, collectively referred to as the original error. The original error of the process system mainly includes:

- Q: What are the oyster processing companies?

- printed posters printing desk calendar printing calendars printing business cards printing envelopes printing paper printing stickers printing other commercial printing processing books printing processing paper processing 2 processing laser plus .. The

Send your message to us

BX-510 High-precision Slitting Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords