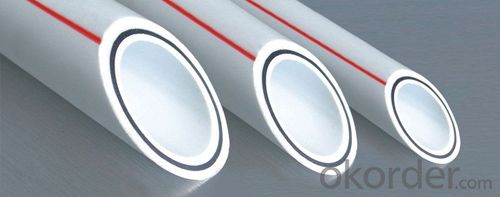

New PPR Household Plastic Pipe with Good Price and Durable Quality Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Describe Of Products:

The comprehensive technical performance and economic indicator of PP-R are much better than galvanized pipe, UPVC pipe, polyethylene-aluminum compound pipe, PE-X (cross-linked polyethylene) and polybutylene pipe etc. For this reason PP-R is the leading products and widely used for feed-water piping in developed countries in Europe and America.

Nowadays PPR pipes win more attention and have been used all over the whole world more widely with its excellent sanitization performance, high heat resistance, compression resistance, corrosion resistance, pliability and seismic performance which make PP-R the real environmental friendly pipe.

Specifications:

Brand: CMAX

Product name: cap

Shape: equal

Head code: round

Type: PPR fittings

Material: PP-R, PP-RCT

Size: 20mm-110mm

Working temperature: 0-95℃

Working life: 50 years

Working pressure: PN25

Technics: casting

Connection: welding

PPR Pipes Advantages:

1. Greatly reduced linear expansion coefficient, only 1/4 of that of PPR.

2. 100% oxygen tightness, suitable for heating system.

3. Improved resistant to impulse under low temperature, resistant to UV-rays.

4. Easily detected by detector when embedded, owing to the metal layer.

FAQ

Q: What you offer?

A: Any kinds of goods you need, just send us the request, we will reply you back with the details very soon.

Q: Product quality and delivery time?

A: Normally 7-15 days after the order confirmed, we will collect the goods and inspect each of the items and send you the inspection photos for you to confirm.

Q: What's the regular shipping port?

A: Ningbo, Shanghai.

Q: What's your payment?

A: T/T or L/C at sight

- Q:Can plastic pipe fittings be used for chemical processing systems?

- Plastic pipe fittings can be used for chemical processing systems, but it is important to choose the right type of plastic that is compatible with the chemicals being used. Certain plastics, such as PVC, CPVC, and PTFE, are commonly used in chemical processing due to their chemical resistance properties. However, it is crucial to consult with experts and consider the specific application requirements before selecting plastic pipe fittings for chemical processing systems.

- Q:Can plastic pipe fittings be used for ventilation systems?

- Yes, plastic pipe fittings can be used for ventilation systems. They are commonly used in residential, commercial, and industrial applications due to their durability, corrosion resistance, and ease of installation. However, it is important to ensure that the plastic material used is suitable for ventilation purposes and meets the necessary fire safety and building code requirements.

- Q:Are plastic pipe fittings resistant to thermal expansion and contraction?

- Yes, plastic pipe fittings are generally resistant to thermal expansion and contraction. They are designed to withstand temperature changes without significant deformation or damage. However, it is important to choose the appropriate type of plastic material for the specific application and consider the temperature limits specified by the manufacturer to ensure optimal performance.

- Q:Are plastic pipe fittings more cost-effective than metal ones?

- It depends on the specific application and requirements. Plastic pipe fittings are generally more cost-effective than metal ones in terms of upfront costs, as they are typically cheaper to purchase. However, metal fittings may offer advantages in terms of durability and longevity, reducing the need for frequent replacements. Additionally, metal fittings may have higher pressure and temperature ratings, making them more suitable for certain high-demand applications. Therefore, it is important to consider factors such as intended use, lifespan, and maintenance costs when determining the overall cost-effectiveness of plastic versus metal pipe fittings.

- Q:Are plastic pipe fittings resistant to gasoline and oil?

- Yes, plastic pipe fittings are generally resistant to gasoline and oil.

- Q:Can plastic pipe fittings be used in geothermal systems?

- Yes, plastic pipe fittings can be used in geothermal systems. Plastic fittings are commonly used in geothermal systems due to their durability, resistance to corrosion, and ease of installation. They are also cost-effective and provide good thermal conductivity, making them suitable for use in geothermal applications.

- Q:Are plastic pipe fittings resistant to earthquake vibrations?

- Plastic pipe fittings can offer some level of resistance to earthquake vibrations, but it ultimately depends on the specific material and design of the fittings. Certain types of plastic pipe fittings, such as those made from high-density polyethylene (HDPE), are known for their flexibility and ability to absorb vibrations. However, it is important to note that no material is completely immune to the effects of earthquakes, and the overall resilience of a plumbing system also relies on proper installation and reinforcement techniques.

- Q:Can plastic pipe fittings be used for food processing facilities?

- Yes, plastic pipe fittings can be used for food processing facilities.

- Q:Can plastic pipe fittings be used in pharmaceutical systems?

- Plastic pipe fittings can be used in pharmaceutical systems, but it is important to ensure that the chosen fittings meet the specific requirements and regulations of the pharmaceutical industry. Factors such as material compatibility, cleanability, and resistance to chemicals should be thoroughly evaluated before selecting plastic pipe fittings for pharmaceutical applications.

- Q:What are the common failure modes of plastic pipe fittings?

- Some common failure modes of plastic pipe fittings include leaks, cracks, and joint failures. These can occur due to factors such as excessive pressure, thermal expansion/contraction, chemical degradation, improper installation, or poor quality materials.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

New PPR Household Plastic Pipe with Good Price and Durable Quality Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords