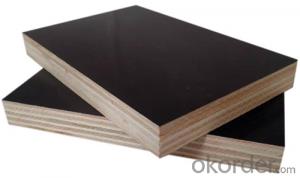

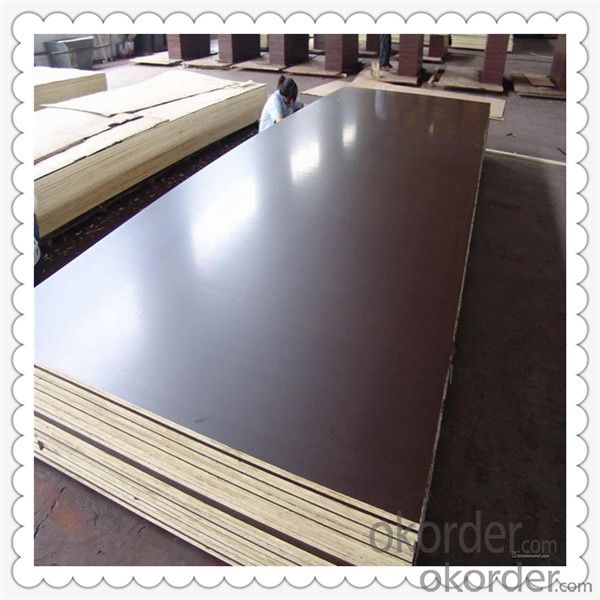

Brown Color Film Faced Plywood with Lowest Price and High Quality

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brown Color Film Faced Plywood with Lowest Price and High Quality

Product Description:

· Type: Plywood

· Place of Origin: Shandong, China (Mainland)

· Usage: Indoor

· Grade: First-Class

· Main Material: Poplar

· Formaldehyde Emission Standards: E2

· Plywood Type: Veneer Boards

· Veneer Board Surface Finishing: Double-Sided Decoration

· Veneer Board Surface Material: Teak

· Face/back: teak, oak, beech, ash walnut, sapele etc

· Thickness: 2.6mm,3.0mm,3.6mm,4.0mm,4.6mm,5.2mm 12mm,9mm,as your request

· Core: poplar, combi, hardwood, MDF

· Glue: melamine: MR, E2,E1

Product Specification:

Name | Fancy Plywood |

Size | 1220mmx2440mm or 915x2135mm |

Thickness | 2.0mm---18mm |

Thickness Tolerance | ±0.2mm to ±0.3mm |

Core | poplar core & harewood core, combi or as agreed. |

Face/Back | Nature ash, Sapeli, Red Oak, White Oak, Teak, steam Beech, Okoume, Cherry, Walnut, |

Glue | WBP, Melamine, E0, E1, E2, MR |

Grade | AAA, AA, A or as agreed. |

Moisture | Below 12% at time of shipment. |

Usage | Decoration, furniture, construction. |

Package | Inter packing: 0.20mm plastic bag. Outer packing: pallets are covered with plywood or carton and then steel for strength. |

Delivery time | 20 days on receipt of deposit or original L/C. |

Min Order | 50 cubic meter |

Payment terms | L/C at sight, T/T30% as deposit, |

Supply ability | 4000 cubic meter/month |

Main market | Middle East, Southeast Asia, East Asia, South Asia Africa etc. |

Packaging & Delivery:

· Inter packing: 0.20mm plastic bag.

· Outer packing: pallets are covered with plywood or carton and then steel for strength

· Delivery Detail: 30 days after receiving LC or deposit

Company Info:

China National Building Material Group Corporation (CNBM for short) was establish in 1984, a Central Enterprise under direct supervision of State- owned Assets Supervision and Administration Commission of the State Council of China.

As of the end of 2000, CNBM has 492 member companies under management around the world, of which 5 were A-share listed holding companies and 2 were H-share listed. CNBM has total assets exceeded RMB 110 billion, and more than 100,000 employees.

CNBM is the largest comprehensive building material industrial group in China that integrates scientific research, manufacturing and logistics into one entity.

OKorder.com is an online building materials trading platform funded by CNBM (listed 267th on Fortune Global 2014) and is operated by CNBM International. CNBM International has more than 20 years trading experience and has established close business relationships with clients from over 160 countries.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q: Solid wood sandwich board how much money a piece

- Manufacturers to take the words of 185 yuan, other places to more than 200

- Q: What is the foam in the color steel foam sandwich panel?

- Commonly used PU, EPS, XPS these three

- Q: Color steel sandwich panel door how to do?

- Color steel sandwich panel door how to do? This large number of doors in the clean room area, it has ready-made aluminum alloy assembly can be. A small amount can be made with the annex to the material package, with riveting can be.

- Q: The foam sandwich panels of the insulated chicken coop are burned! How to do hollowing out?

- Magnesium cement curing to release a high heat, generally in the 1000 ~ 1350J / gMgO, and the heat release rate is very fast, the highest reaction system center temperature up to 150 degrees Celsius. Ordinary Portland cement hydration heat is only 300 ~ 400J / g, can be seen magnesite cement is the ordinary cement hydration heat 3 to 4 times. As can be seen from the above data, especially in the summer high temperature production, must strictly control the magnesite cement curing process. At present in Hebei Wen'an, Cangzhou area, in order to save production space, usually finished a board, and then according to this board for the operating platform in the above do 3 to 5, we all know, thermal conductivity of foam material is poor, and Ling Magnesium cement curing is a fast high heat process, so the production often encountered due to exotherm is too high and burned foam board situation, that is, "burn board" "hollowing" phenomenon.

- Q: Activity board room C-shaped steel and Caigang sandwich panel is how to connect the seal?

- This is the plug without sealing if you need to seal and then plug the sealant on the line

- Q: Color steel rock wool sandwich board price how much

- The price by region, quality and demand to go, Tianjin is rock wool board manufacturers more cities, a single rock wool board, then many can do 40 or so per square meter

- Q: What is eps insulation corrugated sandwich panels

- EPS Chinese name is made of polystyrene, polystyrene resin is the third largest variety, the relative density of 1.05 ~ 1.06, heated to 90 ~ 110 degrees, the volume can be expanded 5 to 50 times, is a heat, Noise, shock, water, acid and other properties of foam.

- Q: I would like to ask the color steel tile sandwich panels can cover the chicken coop? Does it have a good insulation effect?

- Can be, but the traditional ceiling color steel tile sandwich panels generally composite 10 cm thick white polystyrene foam insulation board, the insulation effect is not very good, this is because the thermal conductivity of polystyrene foam board is relatively high (thermal conductivity 0.035W / (m · K ) Above, plus foam and foam board between the gap, the temperature is very serious, comprehensive actual thermal conductivity is generally higher than 0.05. The new polyurethane spray insulation material can be directly sprayed on the color steel tile, the thermal conductivity is low, only 0.022-0.024W / (m · K), insulation effect is 2-3 times the polystyrene board, is the insulation of all insulation materials Especially excellent material. Because the polyurethane in the construction of the use of direct spray molding technology, so that the polyurethane foam layer without patchwork as a whole to form a complete impermeability, fundamentally put an end to the possibility of deep water along the seam along the seam. Which play a preservative and waterproof effect.

- Q: Color steel sandwich panel 75 (0.5 / 0.3) × 1200/1000 said what

- Generally rare 1.2 m and 1.0 m of the board .75 that is certainly the thickness of the sandwich, mm, 0.5 and 0.3 that is certainly the thickness of the metal is also mm. General raw materials are 1 m and 1.2 m, do it , Is 960mm, 950mm, 1150mm.

- Q: We are the construction unit to the scene into the decoration with the sandwich panels and fire retardant coating supervision requirements were re-test and then also use a good brush-resistant paint sandwich panels to do re-examination Will this want to detect what the purpose of what is the detection of the project. Good people to help answer Thank you

- The purpose of the test is whether the material meets the design requirements The item is refractory grade

Send your message to us

Brown Color Film Faced Plywood with Lowest Price and High Quality

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords