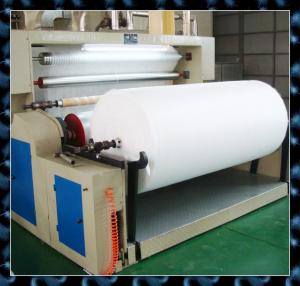

Bleaching Machinery J

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 2 Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Bleaching Machinery J

1. special medical gauze & bandage weaving machine,plain fabric

2. Machine working width:150cm

3. Fabric max width:145cm

4. Fabric min width:80cm

5. R.P.M:500-600

6. Mechanical take-up,mechanical let-off

7. Thread count:7-20pick per inch

8. Cotton yarn:25s-40s

9. warp beam diameter:800mm ,cloth roller diameter will be 800mm at most.

10. if install big package,the cloth roller diameter will be 1200mm at most.

11. Production capacity:depends on thread count and R.P.M

e.g thread count is 15pick per inch,R.P.M is 600.the production per hour should be 61m/h

Mostly,the production capacity is more than 1000 meter per day.

12. air consumption:0

13.one air pump is installed in the machine

Packaging & Delivery of Bleaching Machinery J

Packaging Detail: Pallet packing for long distance

Delivery Detail: 30-35days after reveive deposit or original L/C

Feature of Bleaching Machinery J

1.Adopts the cam with eccentric shaft structure for making terry motion and replaces the old type of knocking bill motion structure. It assures the machine having high reliability of making terry and regulating conveniency.

2.Adopts shout crank arm beating-up motion, increasing greatly the beating-up force during weaving that assures the enough strength the weave the heavy towel.

3.thicker weft beating shaft assures enough beating rigidity, it can weaving the wide fabric more than 2800mm

4.adopts optimized six linkages weft insertion structure, make the weft insertion curve more soft

5.the two electromagnets which controlled the terry raising, controlled by technical program which set by electric control system, It can weaving high and low terry

6.the reed seat and other main parts made up of aluminum alloy, make the machine running faster more stable, more than 200rom speed make it the perfect model to replace the low speed towel rapier loom

1. Manufacturer Overview

| Location | Wuxi, China |

| Year Established | 2006 |

| Annual Output Value | 10-30Setyear |

| Main Markets | Mid East; Eastern Europe; Westen Europen |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | 50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 10000 square meters |

| No. of Production Lines | Above2 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Bleaching Machinery J

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 2 Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords