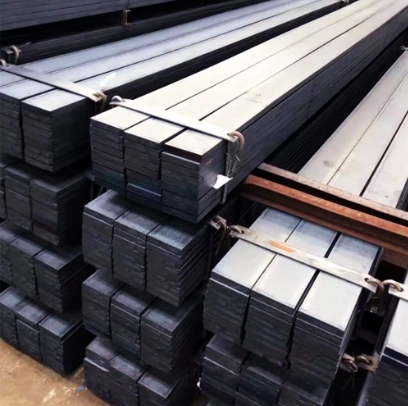

black galvanized steel flat bar hot rolled steel flat bar vertical flat bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

GB

Technique:

Hot Rolled,Cold Rolled

Shape:

flat bar

Surface Treatment:

Galvanized,Black

Steel Grade:

Q195,Q235B,Q355B,SS400,S235JR,ASTM A36

Certification:

SGS,BV

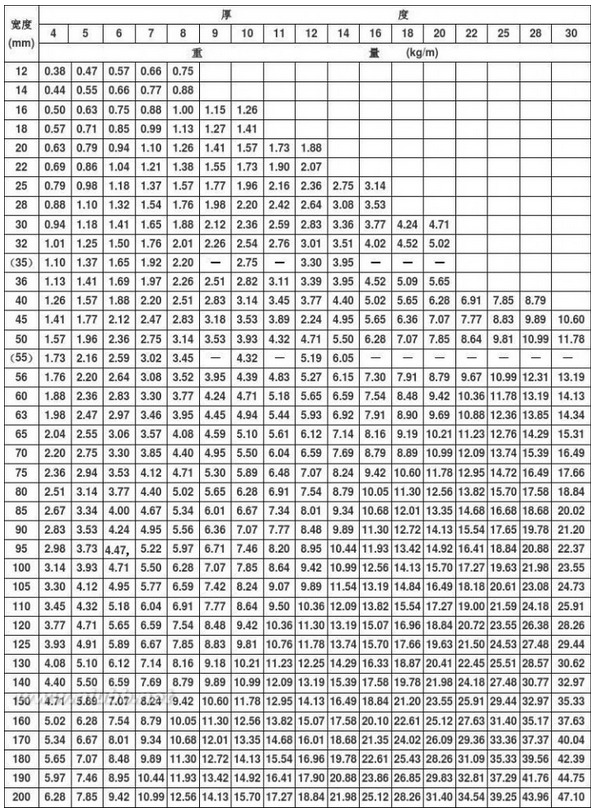

Thickness:

1.3-20MM

Width:

12-150MM

Length:

1-12m or customized

Net Weight:

0.122-23.55kg/m

We supply ms equal & unequal angle bar, channel bar,jis channel, upn, steel i beam,h beam, ipe, ipeaa, steel sheet pile, flat bar, hollow section, tmt bar, wire rod, binding wire, wire mesh, hrc, CRC, gi coil, ppgi, roofing sheet, chequered coil & plates, medium plate, scaffolding systems, prefabricated container houses etc. Also for metal & steel processing.

If you are in the market for any steel products, please feel free to contact us.

- Q: What are the common standards or specifications for steel flat bars?

- Steel flat bars adhere to various common standards and specifications to guarantee uniformity and excellence in their production and utilization. Some well-known standards are as follows: 1. ASTM A36/A36M: This standard sets out the prerequisites for carbon structural steel, encompassing steel flat bars. It covers different measurements, chemical composition, mechanical properties, and tolerances. 2. ASTM A108: This specification outlines the requirements for carbon steel bars, which include flat bars, utilized for general structural purposes. It encompasses various grades and classes of carbon steel, along with their chemical composition, mechanical properties, and tolerances. 3. ASTM A666: This standard deals specifically with the requirements for austenitic stainless steel flat bars. It provides specifications for chemical composition, mechanical properties, dimensions, and surface finishes. 4. EN 10058: This European standard defines the dimensions, tolerances, and technical delivery conditions for hot-rolled flat steel bars. It covers different steel grades and offers guidelines for the manufacturing process and surface quality. 5. JIS G3101: This Japanese standard establishes general requirements for hot-rolled steel plates, sheets, and strips, including flat bars. It includes specifications for chemical composition, mechanical properties, dimensions, and tolerances. It is crucial to note that specific industries or applications may impose additional requirements or standards for steel flat bars. For instance, the construction industry often refers to particular local building codes or standards, while the automotive industry may have its own exclusive specifications. Hence, considering the intended use and consulting the relevant standards and specifications are essential to ensure compliance and suitability for a specific project or application.

- Q: What are the common methods of surface protection for steel flat bars?

- The common methods of surface protection for steel flat bars include painting, galvanizing, powder coating, and applying protective coatings such as oil or wax.

- Q: Are steel flat bars suitable for railway tracks?

- Railway tracks cannot be made from steel flat bars as they lack the required strength and structural integrity to support the weight of trains and prevent track deformations. Steel rails specifically designed for railway tracks are capable of withstanding the heavy loads and constant stress caused by moving trains. Additionally, railway tracks must be able to handle significant dynamic loads, vibrations, and thermal expansion, which steel flat bars are not designed to endure. If steel flat bars were used instead of proper railway tracks, it would pose a safety risk, leading to frequent maintenance and potential derailments due to premature wear and tear. To ensure safe and efficient train operations, it is crucial to use specialized steel rails that are specifically engineered for railway applications.

- Q: How are steel flat bars priced?

- Steel flat bars are priced based on several factors. The main determinants of steel flat bar pricing include current market conditions, raw material costs, the manufacturing process, and any additional expenses related to transportation, labor, and overhead. Market conditions play a significant role in determining steel flat bar prices. Prices tend to rise when there is high demand and limited supply of steel. Conversely, prices may decrease when there is an oversupply or weak demand. Factors such as global economic conditions, industry trends, and geopolitical factors can all influence market conditions and subsequently impact pricing. The cost of raw materials is another crucial factor in determining steel flat bar prices. The cost of ingredients used in steelmaking, such as iron ore, coal, and other alloys, directly affects the overall production cost. Fluctuations in raw material prices can lead to fluctuations in steel flat bar prices. The manufacturing process also affects steel flat bar pricing. The complexity, efficiency, and scale of the manufacturing process can influence the production cost and, consequently, the selling price. The cost of labor, energy, and equipment maintenance also play a role in determining the final price. In addition, transportation costs are taken into account when pricing steel flat bars. The distance between the manufacturing facility and the buyer's location, as well as any associated logistics and handling costs, can impact the overall pricing. Overall, the pricing of steel flat bars is determined by a combination of market conditions, raw material costs, manufacturing processes, and transportation expenses. It is important for buyers to stay informed about these factors in order to understand the pricing dynamics in the steel industry.

- Q: Between the MEB and the power distribution cabinet with wire with the flat and why

- How many will do is a box, the basement has the condition to make the ring to spread the flat steel (copper) to take one circle, many places reserve the ground terminal box foundation to attract, the access flat steel belt;

- Q: Can steel flat bars be used in automotive applications?

- Steel flat bars are indeed applicable in automotive settings. Their strength, durability, and versatility are well-established, rendering them suitable for a range of automotive components and structures. For instance, they can be utilized in constructing chassis frames, body panels, suspension components, and even custom parts. The remarkable tensile strength of steel flat bars enables them to withstand the considerable forces and loads encountered by automotive parts during operation. Moreover, they can be easily shaped, welded, and formed to meet the precise design requirements of automotive applications. Overall, the utilization of steel flat bars in automotive settings is widespread and widely acknowledged due to their exceptional mechanical properties and cost-effectiveness.

- Q: What are the different types of surface finishes for aluminum steel flat bars?

- There are several types of surface finishes that can be applied to aluminum steel flat bars to enhance their appearance and protect them from corrosion. Some of the most common types of surface finishes for aluminum steel flat bars include: 1. Mill Finish: This is the basic finish that is typically applied to aluminum steel flat bars straight from the mill. It has a natural, untreated appearance with a slightly rough texture. 2. Anodized Finish: Anodizing is an electrochemical process that creates a protective layer on the surface of the aluminum steel flat bars. This finish provides increased corrosion resistance and can be dyed to achieve different colors. 3. Polished Finish: Polishing involves mechanically smoothing the surface of the aluminum steel flat bars to create a reflective and shiny finish. This finish is often used for decorative purposes and can enhance the aesthetic appeal of the metal. 4. Brushed Finish: Brushing is a process where a series of fine abrasive pads or brushes are used to create a textured surface on the aluminum steel flat bars. This finish gives the metal a satin-like appearance and helps to hide scratches and fingerprints. 5. Powder Coated Finish: Powder coating involves applying a layer of dry powder onto the surface of the aluminum steel flat bars and then baking it to create a durable and protective coating. This finish is available in a wide range of colors and provides excellent resistance to wear, weather, and chemicals. 6. Painted Finish: Painting is a common surface finish for aluminum steel flat bars, especially when specific colors or patterns are desired. Paint can be applied in various ways, such as spraying or dipping, and provides an additional layer of protection against corrosion. It is important to consider the specific requirements of your application and the desired aesthetics when choosing the appropriate surface finish for aluminum steel flat bars.

- Q: Round bar, flat steel, not reinforced

- Round steel: 5.5-25 mm small round bars are mostly supplied by straight strips. They are commonly used as reinforcing bars, bolts and various mechanical parts. They are more than 25 millimeters of round steel. They are mainly used in the manufacture of mechanical parts or as seamless steel tube billets.

- Q: What is the bending capacity of a steel flat bar?

- The ability of a steel flat bar to withstand bending forces without breaking or permanently deforming is known as its bending capacity. Several factors, including the steel's dimensions, thickness, composition, the applied load, and the type of bending being performed, influence the bending capacity. Steel flat bars generally have a high bending capacity due to their inherent strength and durability. To determine the specific bending capacity of a steel flat bar, engineers can calculate the maximum bending moment it can withstand before failure occurs. This calculation involves using engineering formulas and principles like the moment of inertia and the steel's yield strength. It should be noted that the bending capacity of a steel flat bar can vary depending on its grade or alloy. Different grades of steel have distinct mechanical properties, such as tensile strength and yield strength, which directly affect their bending capacity. Therefore, considering the specific grade and composition of the steel flat bar is crucial when assessing its bending capacity. Furthermore, the shape and dimensions of the steel flat bar also significantly impact its bending capacity. Wider and thicker flat bars generally have higher bending capacities compared to narrower and thinner ones. This is because the increased cross-sectional area provides more resistance against bending forces. In conclusion, the bending capacity of a steel flat bar is influenced by factors like the grade of steel, dimensions, and applied load. To accurately determine the bending capacity, consulting engineering references or professionals who can perform calculations based on the specific properties of the steel flat bar is recommended.

- Q: What are the weight and strength properties of steel flat bars?

- Steel flat bars are known for their high strength and durability. The weight of steel flat bars can vary depending on their dimensions, but they are generally heavier than other materials used for similar purposes. The strength properties of steel flat bars make them suitable for applications requiring load-bearing capacity and resistance to bending or deformation.

Send your message to us

black galvanized steel flat bar hot rolled steel flat bar vertical flat bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Related keywords