Xps Extruded Polystyrene Board Bathroom Tile Board with Core XPS and Fiberglass

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Insulation & waterproofing solutions - CMAX Bathroom Tile Board with Core XPS and Fiberglass

Product name :

CMAX board (as known as construction board, tile backer board, insulation backer board, waterproof backer board, wet room backer board, XPS board.)

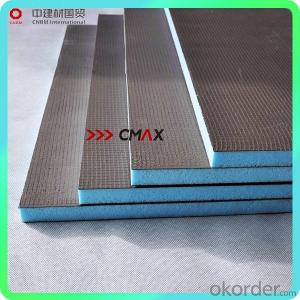

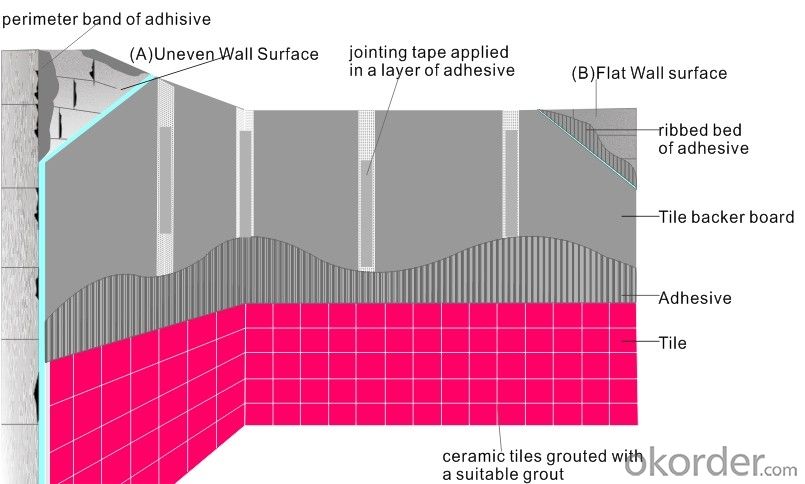

Product structure of Bathroom Tile Board with Core XPS and Fiberglass:

CMAX boards are made of high-performance waterproof extruded polystyrene (XPS Board), it has a 0.75mm coating on either side comprising a glassfiber mesh embedded in a polymer cement mortar.

Outstanding characteristics of Bathroom Tile Board with Core XPS and Fiberglass:

Both insulation and waterproof.

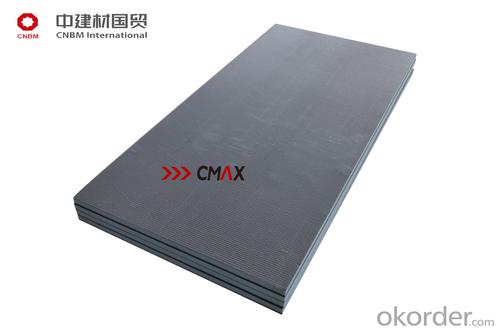

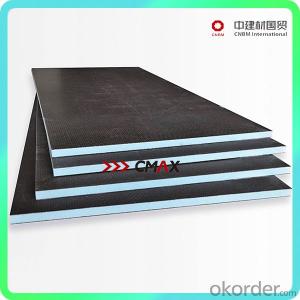

Product appearance of Bathroom Tile Board with Core XPS and Fiberglass:

The boards have straight edges. The color of the surface is grey and the core material is light blue.

Working temperature range of Bathroom Tile Board with Core XPS and Fiberglass:

50 to +80 °C

Standard dimensions and weight of Bathroom Tile Board with Core XPS and Fiberglass:

Thickness(mm) | Weight(kg/m²) | Length by width(mm*mm) |

6 | 2,7 | 1200 x 600 |

10 | 2,9 | 1250 x 600 |

12 | 3,0 | 2500 x 600 |

20 | 3.1 | 2500 x 600 |

30 | 3,3 | 2500 x 600 |

50 | 4,2 | 2500 x 600 |

The board has the following tolerances:thickness:± 2mm width:± 2mm length:± 3mm.

Reaction to Fire of Bathroom Tile Board with Core XPS and Fiberglass:

The boards are classified as class E according to EN 13501-1. When the boards are covered with tiles, their fire performance should comply with local construction laws and regulations.

Effect on indoor environment of Bathroom Tile Board with Core XPS and Fiberglass:

CMAX board has been assessed as not emitting any particles, gases or radiation that may have a negative effect on the indoor climate or to have any significant effect on health.

Environmental declaration of Bathroom Tile Board with Core XPS and Fiberglass:

The product does not contain any substances on the observation list of dangerous substances published by the national environmental authorities.

Main applications of Bathroom Tile Board with Core XPS and Fiberglass:

Used as a watertight layer on walls and floors in houses, hotels and other wet areas such as bathroom, shower room.

Other applications of Bathroom Tile Board with Core XPS and Fiberglass:

Other places to be insulated and waterproofed.

Applications of Bathroom Tile Board with Core XPS and Fiberglass:

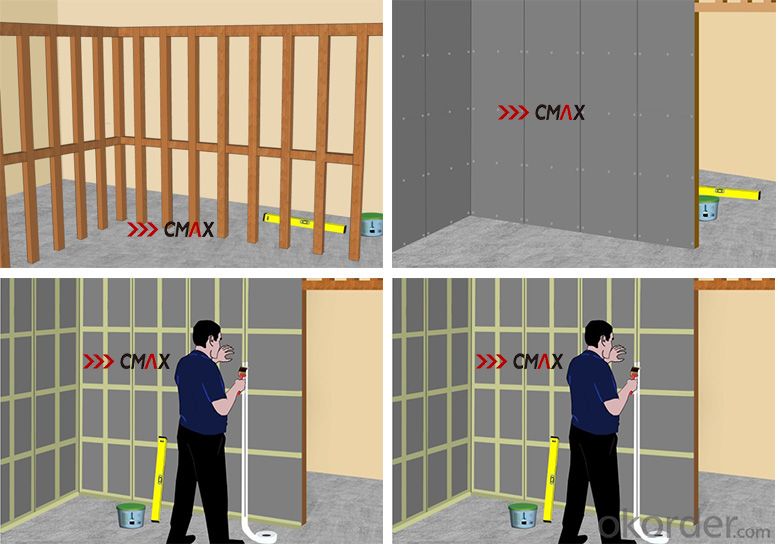

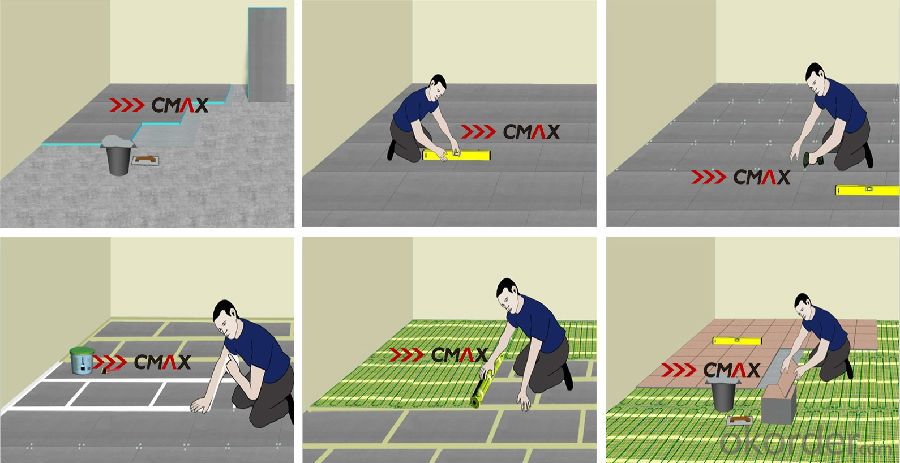

1. as a watertight layer on walls and floors in wet rooms and bathrooms.

2. as an insulation layer in under floor heating to avoid heat loss.

3. as partition walls in wood or steel frames.

4. substitute for gypsum board and fiber cement board; insulation and waterproofing; lighter so that more easily to install.

5. As enclosures for bathtubs, water pipes, etc.

6,Can very easily and fast formed to be small shelves, washbasins, shower benches and soap boxes.

7. Combining with CMAX curved/shapeable boards, kinds of decorative models can be made with your infinite creativity.

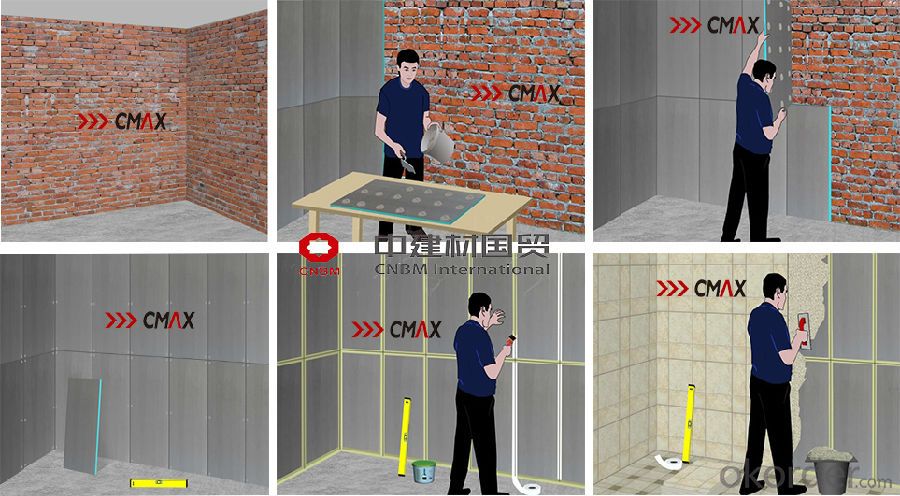

Fixing of Bathroom Tile Board with Core XPS and Fiberglass:

Choose a way to fix CMAX board according to the substrate to be fixed. Normally, using modified tile adhesive for solid concrete wall/floor and strengthened by mechanical fixings when necessary while only using mechanical fixings for wood and steel frames.

Reinforcement of Bathroom Tile Board with Core XPS and Fiberglass:

1. Dry areas: reinforce all joints between boards, floors and walls by 125px or 250px wide self-adhesive tape.

2. Wet areas: reinforce by suitable waterproof tape.

Waterproof strengthen of Bathroom Tile Board:

1. Strengthening all joints between boards, floors, walls and mechanical fixings placements by suitable waterproof tape.

2. Strengthening joints between walls, outside corners and inside corners by special corners.

3. Sealing pipe holes with special waterproof tape.

4. Strengthening once again by waterproof glue, liquid tanking membrane, tanking membrane paint, etc. when necessary.

Coating of panels of Bathroom Tile Board:

Should always be covered by ceramic tiles, mosaics or other equivalent non-fireproof materials after installation.

FAQ:

1.

Q: Are you a manufacturer of insulation materials?

A: Yes. ourselves manufacturer of thermal insulation board.

2.

Q: What is the seaport near your plants?

A: The nearest port is Shanghai Port, there are about 100km from the port to our plant in Shanghai.

3.

Q: What is annual production capacity of your main products?

A: 200,000 piecs per month.

4.

Q: Do you have your own brands? And what are they.

A: Yes. we are a fortune 500 company, our brand is "CMAX"

5.

Q: Is sample available for testing?

A: Yes. The sample is free.

We do OEM as well. Welcome to make an enquiry and we will give you quick response in 12 hours!

- Q: How is the flame and combustible defined by the naked eye? I burn the B1 level and B2 level XPS board is different? Question added: detection time is longer, can quickly and intuitively identified? More

- Mainly for insulation to reduce heat loss. So use a good insulation material insulation. Hope it helps you.

- Q: Roofing the top of the extruded polystyrene insulation board generally how much weight ah?

- The bar spacing is called 'step distance', 1.2 ~ 1..1.8m, no minimum spacing, maximum 1.8m. Pole spacing 1..1..1.55m, no minimum spacing, maximum 1.55m. See JGJ130 Haifa Fenzhuang Curcuma Gufeng Koufukai -2011 "Construction Construction Fastener Steel Scaffolding Safety Technical Specification" 'Structural Requirements'.

- Q: Why extruded board (XPS board) is the best insulation board material

- Scaffolding from the erection of the main points on the scaffolding, cantilevered scaffolding and climbing three. High-level general use of floor and cantilever set of set enough to set the dumplings rush to set off the boat to Long. If the number of layers to more than 30F, and the structure can be relatively simple climbing scaffolding, climbing the advantage of the higher the height of the higher relative to the cost of picking. I am a professional scaffolding company, do not understand can ask me. I hope I can help you.

- Q: Sound insulation and polystyrene insulation board which sound insulation better?

- But its assembly is more complex and is not conducive to high-level construction, safety performance Dingzao cut to cut the salt tax is also poor, if the assembly is very easy to accident, and susceptible to natural factors and reduce its safety, As more and more emphasis on the protection of green today, it is bound to be replaced by steel scaffolding fastener type steel scaffolding with easy processing, easy handling, versatility and other advantages, is currently the largest use of China, the most common use of a scaffolding, but this scaffolding security is equally poor, the construction efficiency Low, scaffolding maximum erection height of 33 meters, can not meet the development needs of high-rise building construction bowl button assembly disassembly is relatively simple, the assembly performance is also good, more in the United States, China seems to use is not very wide But personally think that the future bowl button scaffolding will certainly be popular, there are prospects aluminum scaffolding is mainly lightweight, corrosion-resistant But not a high degree of construction, can not be high-level construction the disc does not seem to use the fastener with the bowl button type, universal joint do not understand So, personally think that in China fastening scaffolding or the mainstream, bowl button-style prospects are good

- Q: Steel plant wall plug color steel tile, the glass glass inside the glass, hanging in color steel, how construction? How is the cost associated with a single sandwich panel?

- Flexible waterproof casing for Shanghai Geng high international 薨 uan arm for the seismic fortification requirements of the area, the pipeline through the walls to withstand vibration and pipe telescopic deformation, or a strict waterproof requirements of the building (building) buildings

- Q: Extruded Polystyrene Board, Polystyrene Foam Board and Expanded Polystyrene Board

- Market price, no quota. According to the different brands, the price is different! I hope useful to you!

- Q: The traditional ceramic insulation board, the existing thermal insulation coating in addition to the process and the construction period there are similarities and differences there are differences? Which energy-saving building is better?

- Because the middle of the lap will lead to fasteners, fasteners can not withstand such a large force, and the top can withstand

- Q: What is the difference between an extruded board and an XPS extruded board?

- Foam plastic plate insulation effect, hinder the outdoor temperature affect the indoor temperature, can play the role of Dongnuanxialiang. . the snow has the role of heat insulation, isolated 礌 礌 礌 蕺 蕺 蕺 蕺 scrapped wheat and outside the air contact, on the one hand to prevent the wheat freeze and death, on the other hand have the effect of refrigeration . to the thicker glass When the water is turned down, the inner glass is exposed to rapid heat, and the outer glass is in contact with the cold air of the cup, so that the expansion of the inner and outer walls causes the difference.

- Q: Steel structure rock wool sandwich wall panel what the amount of this set

- Extruded polystyrene board with XPS insulation board is no different, because it is the same thing two kinds of name. Extrusion polystyrene board full name is extruded polystyrene foam board, referred to as extruded plate, also known as XPS board, extruded polystyrene board. Extrusion polystyrene board use: 1 & gt; widely used in wall insulation, flat concrete roof and steel roof insulation; 2 & gt; for low temperature storage ground, parking platform, airport runway, highway and other areas of moisture insulation. Extruded plate is polystyrene resin supplemented by polymer in the heating and mixing at the same time, into the catalyst, and then extruded out of continuous closed-cell foam foam foam, the internal independent of the closed bubble structure, It is a kind of environment-friendly insulation material with high compression resistance, low moisture absorption, moisture-proof, airtight, light weight, corrosion resistance, super-aging resistance (almost no aging for long-term use) and low thermal conductivity. Extruded board is widely used in dry wall insulation, flat concrete roof and roof insulation of steel roof, low temperature storage floor, low temperature floor radiant heating heating pipe, parking platform, airport runway, highway and other areas of moisture insulation, Frost heave, is the construction industry inexpensive, excellent quality of the insulation, moisture-proof material.

- Q: How to distinguish between good and bad insulation board insulation board

- Class flexible management refers to the class teacher in the student's psychological and behavioral laws on the basis of the use of non-mandatory way, in the minds of students to produce a potential persuasive, the use of the class teacher's own positive factors to influence and guide students

Send your message to us

Xps Extruded Polystyrene Board Bathroom Tile Board with Core XPS and Fiberglass

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords