Aluminum Strips Lowes New Product Coil Aluminum Composite Panel Roller

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

Stable aluminium is created when hydrogen fuses with magnesium, either in large stars or in supernovae. It is estimated to be the 14th most common element in the Universe, by mass-fraction. However, among the elements that have odd atomic numbers, aluminium is the third most abundant by mass fraction, after hydrogen and nitrogen.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

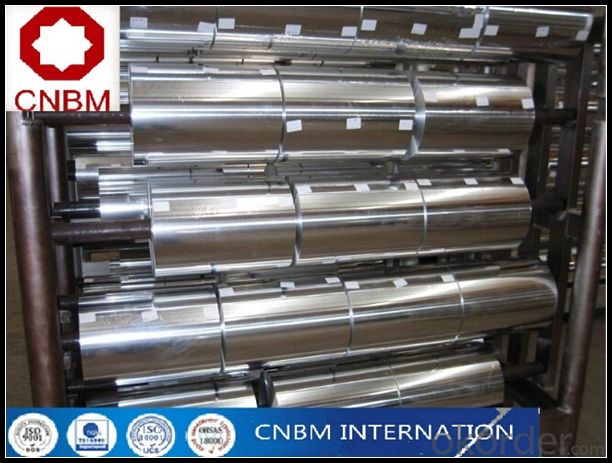

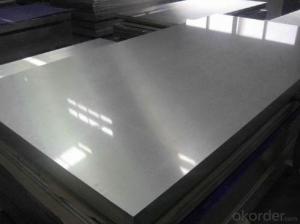

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: This question asks for a method to measure the thickness of aluminum siding material.

- <p>To determine the thickness of aluminum siding, you can use a digital caliper or a micrometer, which are precise measuring tools. Place the caliper or micrometer at the edge of the siding, ensuring it's perpendicular to the surface, and take a measurement. Another method is to use a magnetic thickness gauge if the siding is coated, as this tool can measure the thickness of non-magnetic coatings on magnetic metals. Always check the manufacturer's specifications for the siding as well, as they often provide thickness information.</p>

- Q: What specific conditions or considerations are needed when installing aluminum strips for flooring in cold weather conditions?

- <p>In cold climates, using aluminum strips for flooring requires considering thermal expansion and contraction due to temperature changes. It's crucial to allow for adequate expansion gaps to prevent buckling or warping. Additionally, it's important to use aluminum alloys with good low-temperature toughness to prevent brittleness. Proper insulation and a stable subfloor temperature are also necessary to maintain the integrity of the flooring. Always consult with a professional or manufacturer for specific recommendations tailored to the climate and project requirements.</p>

- Q: What is the best capacitance for an aluminum ribbon tweeter?

- You can choose to ask questions in the right category so that you know more questions and answer more.

- Q: What specific tools or equipment are necessary to install aluminum strips?

- <p>To install aluminum strips, you generally need a few basic tools. A measuring tape is essential for accurate placement. A utility knife or a metal cutting tool is necessary for cutting the strips to the correct length. A level is crucial to ensure the strips are straight. A rubber mallet or a hammer can be used to secure the strips in place. Adhesive, such as construction adhesive or double-sided tape, is often required to attach the strips. Safety equipment like gloves and safety goggles should be worn to protect against sharp edges and debris.</p>

- Q: What benefits does aluminum provide compared to other metals when used for roofing applications?

- <p>Aluminum offers several advantages for roofing, including its lightweight nature, which reduces structural load. It is highly resistant to corrosion, making it suitable for various climates and environments. Aluminum's malleability allows for easy shaping and forming, enabling complex designs. It also has excellent reflectivity, which can help in reducing heat absorption and improving energy efficiency. Additionally, aluminum is recyclable and has a lower environmental impact compared to some other metals. These properties make aluminum a popular choice for roofing materials.</p>

- Q: What unique considerations must be taken into account when storing and transporting aluminum strip stock?

- <p>Yes, there are special requirements for storing and transporting aluminum strip stock. Aluminum is sensitive to moisture and can corrode, so it must be kept dry. It's also important to avoid scratches and dents, which can occur if the material is mishandled. Aluminum strip stock should be stored in a clean, dry environment, away from chemicals that could cause corrosion. When transporting, it should be secured to prevent movement that could lead to damage. Protective coverings or wrappings are often used to shield the material from the elements and potential physical impacts.</p>

- Q: Does aluminum corrode in a manner similar to rusting?

- <p>Aluminum does not rust in the same way as iron or steel. Instead, aluminum reacts with oxygen in the air to form a thin, protective layer of aluminum oxide on its surface. This oxide layer prevents further corrosion, unlike rust which can compromise the integrity of iron and steel. While aluminum can tarnish or become discolored due to exposure to certain elements or chemicals, it does not rust in the traditional sense.</p>

- Q: What types of aluminum alloys are known for their higher resistance to corrosion compared to other aluminum types?

- <p>Yes, certain types of aluminum alloys exhibit greater resistance to corrosion. These include 3003, 5052, and 5083 aluminum alloys, which contain magnesium and manganese, enhancing their corrosion resistance. Additionally, 6061 aluminum, which contains magnesium and silicon, is known for its good resistance to atmospheric corrosion. These alloys are often used in marine environments and other corrosive conditions due to their superior corrosion resistance.</p>

- Q: This question asks for an overview of the steps involved in the manufacturing of aluminum components used in vehicles.

- <p>The production process of automotive aluminum parts typically involves several key steps: material selection, design, casting or forging, machining, heat treatment, surface treatment, and quality control. Aluminum is chosen for its lightweight and high strength properties. The design phase involves creating detailed plans for the part. Casting or forging shapes the aluminum into rough forms. Machining refines these forms to precise specifications. Heat treatment enhances strength and durability. Surface treatments protect against corrosion and wear. Finally, quality control ensures each part meets industry standards before it is used in vehicles.</p>

- Q: What are the various forms in which aluminum strips can be manufactured?

- <p>Aluminum strips come in a variety of shapes and sizes to suit different applications. Common shapes include rectangular strips, square strips, and round strips. Rectangular strips are the most common and are used in construction, automotive, and packaging. Square strips are often used in electrical applications and for decorative purposes. Round strips are less common but are used in specific industries such as aerospace and medical equipment. Additionally, aluminum strips can be flat, embossed, or have other surface treatments depending on the requirements of the application.</p>

Send your message to us

Aluminum Strips Lowes New Product Coil Aluminum Composite Panel Roller

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords