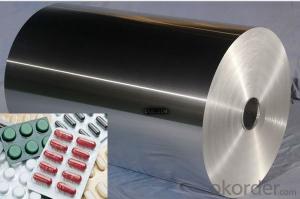

Aluminum High Quality Pharmaceutical Foil for Packing

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 MT / Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Aluminium Pharmaceutical Foil

Alloy: 8006 / 8011 / 8079

Temper: H18 / O

Specifications of Aluminium Pharmcaceutical Foil

Thickness & Tolerance: 0.02 mm - 0.09 mm (+/-6%)

Width & Tolerance: 200 - 1650 mm (+/-1 mm)

Mechancial Properties: Tensile Strength (U.T.S.)≥160 Mpa, Elongation)≥1%

Standard: GB/T3198 / ASTM-B209 / EN546

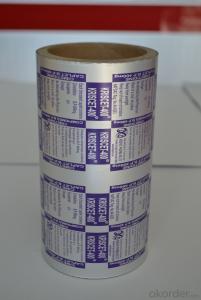

Usage/Application of Aluminium Pharmaceutical Foil

Pharmaceutical packaging

Packaging & Delivery of Aluminium Pharmaceutical Foil

Packing: seaworthy wooden box with pallet

Delivery: to be loaded by 1 x 20 feet container

- Q: Is aluminum a suitable material for manufacturing bicycles and other lightweight vehicles?

- <p>Yes, aluminum is a popular material for making bicycles and other lightweight vehicles due to its high strength-to-weight ratio. It is lightweight, durable, and resistant to corrosion, which makes it an excellent choice for components that need to be strong yet not add excessive weight. Aluminum frames are commonly used in bicycles because they offer a good balance between weight, stiffness, and cost. Additionally, aluminum is widely used in the manufacturing of other lightweight vehicles such as electric scooters, small cars, and even aircraft due to its favorable properties.</p>

- Q: This question asks for methods to protect aluminum from corrosion.

- <p>Aluminum corrosion can be prevented through several methods. One common approach is anodizing, which involves applying a protective oxide layer to the aluminum surface. This process enhances the metal's resistance to corrosion. Another method is using protective coatings such as paints or enamels that act as a barrier against corrosive elements. Cathodic protection, where aluminum is connected to a more easily corroded metal, can also be used. Additionally, ensuring proper design and avoiding contact with aggressive chemicals can minimize corrosion. Regular maintenance and inspection can help detect and address corrosion issues early.</p>

- Q: Is it possible to use pure aluminum to create tools and equipment with increased longevity?

- <p>Pure aluminum is not typically used for making tools and equipment that require durability and strength. While it is lightweight and corrosion-resistant, pure aluminum is relatively soft and lacks the strength needed for most tools and equipment. Alloys of aluminum, which combine aluminum with other elements like copper, magnesium, or silicon, are often used instead. These alloys offer improved strength, hardness, and wear resistance, making them more suitable for long-lasting tools and equipment.</p>

- Q: Is aluminum suitable for use in paint and coating applications?

- <p>Yes, aluminum can be used in paints and coatings. It is often used in the form of aluminum pigments or flakes, which provide a metallic appearance and enhance the durability and corrosion resistance of the coating. Aluminum pigments are also valued for their ability to reflect light and heat, making them useful in applications requiring thermal insulation or reflective properties. Additionally, aluminum can be used in powder coatings, providing a hard, wear-resistant finish.</p>

- Q: Describe the process of aluminum oxide formation in a few sentences.

- <p>Aluminum oxide forms through a process known as oxidation, where aluminum reacts with oxygen in the air. This reaction is typically exothermic and can occur at room temperature, especially in the presence of moisture. When aluminum is exposed to oxygen, it forms a thin, protective layer of aluminum oxide on its surface. This layer prevents further oxidation and is what gives aluminum its corrosion resistance. In industrial settings, aluminum oxide can also be produced through electrolysis of aluminum oxide dissolved in molten cryolite.</p>

- Q: What are the differences between Aluminum Oxide and Aluminum Alloy in terms of their properties and applications?

- <p>Aluminum Oxide and Aluminum Alloy are distinct materials with different properties and uses. Aluminum Oxide, also known as alumina, is a ceramic material with a high melting point, hardness, and electrical insulation properties. It's used in abrasives, electronics, and as a refractory material. In contrast, Aluminum Alloys are composites of aluminum with other elements like copper, magnesium, or silicon, which enhance their strength, corrosion resistance, and malleability. They are widely used in construction, automotive, aerospace, and packaging due to their lightweight and durability.</p>

- Q: Is it safe to use aluminum containers for food and drink in a microwave?

- <p>Aluminum is not recommended for use in microwave-safe containers for food and drink. While some aluminum containers are designed to be microwave-safe, they are typically coated with a non-metallic material to prevent arcing and damage to the microwave. However, most aluminum containers are not safe for microwave use as they can cause sparks and potentially damage the microwave. It's best to use microwave-safe plastics, glass, or ceramics specifically designed for microwave use.</p>

- Q: Is it possible to develop allergies from exposure to aluminum found in food packaging materials?

- <p>While aluminum is commonly used in food packaging materials, the risk of allergic reactions to aluminum is generally low for most people. Aluminum is not a known allergen, and exposure through packaging is typically minimal. However, individuals with a rare condition called contact dermatitis may experience skin irritation from aluminum. For the general population, the risk of allergic reactions due to aluminum in food packaging is negligible. It's always important to monitor any unusual reactions and consult a healthcare professional if concerned.</p>

- Q: Is it possible to enhance the efficiency of solar panels by utilizing aluminum?

- <p>Yes, aluminum can be used to improve the efficiency of solar panels. Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity, which can help in dissipating heat and maintaining optimal operating temperatures for solar cells. It is also used in the manufacturing of solar panel frames, providing structural support while reducing the overall weight of the panels. Additionally, some research suggests that using aluminum in the backsheet of solar panels can enhance their durability and efficiency. However, the extent of efficiency improvement depends on various factors, including the specific design and manufacturing process of the solar panels.</p>

- Q: What specific rules or guidelines are there for incorporating aluminum in construction projects?

- <p>Yes, there are special regulations for using aluminum in construction projects. These regulations vary by country and region but generally include standards for material properties, structural integrity, fire resistance, and environmental impact. For instance, the American Society for Testing and Materials (ASTM) and the Aluminum Association provide guidelines for aluminum usage in construction. Compliance with building codes is crucial, and these codes often specify the grades of aluminum, allowable stress values, and methods of joining. Additionally, considerations for corrosion resistance, thermal expansion, and recycling potential are important. It's essential to consult local building codes and industry standards to ensure compliance when using aluminum in construction.</p>

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 250 Million |

| Main Markets | Mid East; North America |

| Company Certifications | ISO 14001:2004;FDA |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 20-30 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum High Quality Pharmaceutical Foil for Packing

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 MT / Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords