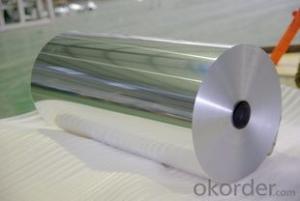

Aluminum Foil Jumbo Roll Mill Finished Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminum Foil Jumbo Roll Mill Finished Roll

Sepcifications:

(1)Alloy 8011 Temper:O

(2)Length:2-300m .

(3)Width: 200-600mm .

(4)Thickness:6-25micron.

Usage:

used for food pack, butter wrap, ice cream, chicken ect

Packing

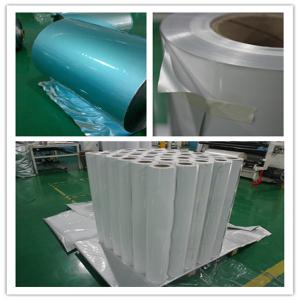

sheet or roll with Carton and pallet, protection packing.

Why Choose Us

(1) OEM service with Various dimensions available

(2) Free samples could be supplied.

(3) High quality with attractive design

(4) More than 20 co-manufacturer parterners to satisfy your any special needs.

(5) Short delivery time

6)Complete After-sale service systerm to be your best consultant

Feature:

(1) It is beautiful, fashionable and practical.

(2) Different sizes can be made and different designs can be printed. We welcome your designs.

(3) Our company specialise in producing aluminum foil products. We have experienced workers and complete production lines. We can ensure the goods in good quality and competitive price.

(4) We welcome you to contact us for business cooperation

Advantage:

Good light-proof,waterproof, moistureproof,high-barrier,

Good printing and flatness,good flexibility effectively avoid light,

prevent leakage, extend the shelf life of contents

Feature:

Our products can be produced according to China GB Standards and the ISO series standards of theInternational Standards Organization,JIS and ASTM.

Kind attention:

Specifications can be customized according to the customer’s requirements..

- Q: Aluminum foil waterproof material, how much does it cost for a square?

- It depends on whether you are using SBS waterproof membrane or self-adhesive waterproof coiled material

- Q: The aluminium foil is melted and glued to the electric ceramic stove. How can I get rid of it? A safe way of not hurting the stove

- Reheated and thawed again.If the area of the foil is slightly larger, you may consider dropping the cold water at the high temperature after heating. But do not control the amount of water dripping. Be careful not to spill the water onto the ceramic panel to damage the panel.

- Q: What about the electromagnetic shielding effect of aluminum foil tape and copper foil tape?

- Shielding effect is the same, because aluminum is easier to oxidize than copper, difficult to weld and other reasons, the general shielding with copper tape.

- Q: Does it hurt much to work in aluminum foil manufacturing enterprises?

- No longer produce a line of aluminum foil contact is not much, and no harm to the human body

- Q: Pure aluminum foil, can withstand the maximum temperature?

- The highest temperature of aluminum foil bag is 121 degrees 30 minutes, generally not more than 130 degrees. Qili Hui

- Q: What is an aluminum foil woven bag?

- (3) high temperature (121 DEG C), low temperature (-50 DEG C), good oil resistance and good incense retention.(4) non-toxic, tasteless, in line with food, drug packaging hygiene standards.(5) good heat sealing property, softness and high barrier property.

- Q: Can foil paper be used in a microwave oven with barbecue?

- This one thing but to free 130 yuan for the security, if not only need to pay 130 yuan plus overhaul costs 35 yuan, because the scope for large to overhaul.

- Q: Will the aluminum foil tape conduct electricity?

- Because aluminum foil is a metal, it will conduct itself. Aluminum foil tape is divided into single conductive aluminum foil tape and double conductive aluminum foil tape

- Q: How do you microwave the chicken wings with aluminum foil?

- If you want to use the microwave oven barbecue, mini baking sheet, please use the light wave heating (remember). Aluminum foil is used to wrap the barbecue items. Grilled chicken wings, wrapped with aluminum foil to prevent live chicken wings, barbecue when oil splash, cause it is difficult to clean the microwave oven, and can prevent the scorched wings.

- Q: Clamp aluminum foil paper with sticky?

- ChinaIncluding the heart ballMain ingredients: 750 grams eel, pork (thin) 200 grams, kilogramShrimp accessories: letinous edodes (fresh) 50 grams, pork (hair) 50 grams, 200 grams of sweet potato powder,Spices: soy sauce 10 grams, 5 grams of salt, monosodium glutamate 3 grams, sesame oil 10 grams, 3 grams of pepper, onion 10 grams

Send your message to us

Aluminum Foil Jumbo Roll Mill Finished Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords