Aluminum Foil Facing Fiberglass Wool Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Aluminum Foil Facing

Aluminum Foil Facing is a kind of film, which is made of by the aluminum foil, fiberglass scrim and Kraft paper. Someone is made of by aluminum and PE woven fabric cloth.

Application of Aluminum Foil Facing

Our aluminum foil facing are mainly used as facing for glass wool insulation, rockwool, mineral wool etc. Also aluminum foil facing is used under roof decking, under attic rafters, over existing attic thermal insulation, in floors, walls and crawl spaces, and in industrial and commercial buildings to block radiant heat coming into house through the roof during the summer and retain indoor heat generated during in winter. ,

Advantage of Aluminum Foil Facing

Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly, no smell and not-toxic;

• Smooth and clear surface;

Packing of Aluminum Foil Facing

1. Waterproof paper then PVC shrinking Film

2. Kraft paper only

3. Woven cloth

4. Kraft paper or Water Proof Film then Metal/wooden pallet

5. (Also as your request. )

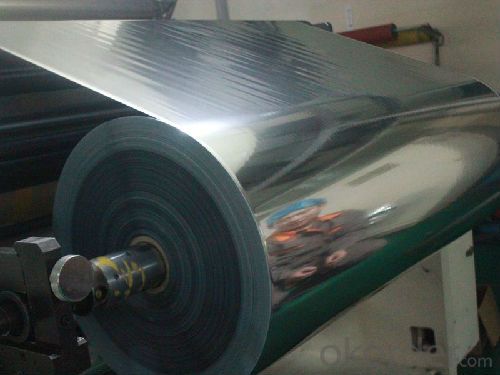

Pictures of Aluminum Foil Facing

Specification of Aluminum Foil Facing

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 88 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 110 50 | ASTM D828 |

Burst strength | N | 30 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C 66°C | No Delamination No Delamination | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Remarks:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of Aluminum Foil Facing and is one of the large-scale professional investment Aluminum Foil Facing bases in China. Annually more than 1000 containers of Aluminum Foil Facing are exported to markets in Europe, America and Japan.

2. What is the storage condition?

The Aluminum Foil Facing should be stored at room temperature and kept from wet and heat source.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: What are the methods to prevent grease stains on aluminum foil after using it for cooking?

- <p>To avoid grease stains on your aluminum foil facing after cooking, consider the following tips: Use a double layer of foil to increase protection, ensuring the foil is large enough to fully cover the cooking surface. Preheat your foil before placing it on the cooking surface to reduce the chance of grease sticking. Clean the foil immediately after use with warm soapy water to remove any grease before it sets. Alternatively, you can use non-stick spray or a light coating of oil on the foil before using it, which can help prevent grease from adhering.</p>

- Q: This question asks for instructions on how to clean aluminum foil facing after it has been used in cooking or baking.

- <p>To clean aluminum foil facing after use, first let it cool down to avoid burns. Then, gently scrape off any food residue with a spatula or the edge of a knife. For stubborn stains, mix a solution of warm water and dish soap, and wipe the surface with a soft cloth or sponge. Rinse with clean water and dry thoroughly. For baked-on food, you can use a plastic scraper or an old toothbrush to gently remove it. Avoid using abrasive materials that could scratch the surface. Regular cleaning will help maintain the integrity and appearance of your aluminum foil facing.</p>

- Q: This question asks for signs or methods to identify if the aluminum foil facing of a product, such as insulation or a jacket, is damaged or defective.

- <p>To determine if your aluminum foil facing is damaged or defective, look for visible signs such as tears, punctures, or holes. Check for any discoloration or rust, which could indicate corrosion. The foil should be smooth and uniform; any irregularities or bubbling might suggest a defect. Additionally, test the integrity by gently pulling or pressing the foil鈥攊f it easily tears or crumples, it may be compromised. For insulation, a damaged foil facing can lead to reduced effectiveness in heat or cold retention, so also consider the performance of the item.</p>

- Q: Is it safe to use pre-cut sheets of aluminum foil for cooking or baking purposes?

- <p>Yes, it is generally safe to use pre-cut sheets of aluminum foil for cooking and baking. Aluminum foil is designed to withstand high temperatures and is commonly used to cover food, line baking sheets, or wrap food for cooking. However, it's important to ensure that the foil does not come into direct contact with the heating element of an oven, as this can cause it to melt or create a fire hazard. Additionally, avoid using aluminum foil with non-stick cookware, as it can damage the non-stick surface. Always follow the manufacturer's guidelines for safe use of aluminum foil in your specific cooking appliances.</p>

- Q: Explain the differences between aluminum foil facing and plastic wrap concerning their safety when used for food storage.

- <p>Aluminum foil facing and plastic wrap are both used for food storage, but they have different properties affecting food safety. Aluminum foil is a metal that provides a good barrier against air and moisture, but it doesn't contain any plasticizers that could potentially leach into food. It's also heat resistant, making it suitable for cooking and baking. On the other hand, plastic wrap is made from polymers and can be affected by heat, potentially releasing chemicals into food if overheated. It's not recommended for use in microwaves or for wrapping hot foods. Additionally, plastic wrap can cling to food, which might lead to direct contact with the plastic material, whereas aluminum foil creates a barrier without sticking to the food.</p>

- Q: What are the various materials used as facings for aluminum foil, and how do they differ from one another?

- <p>Aluminum foil facing materials are used in construction and insulation to provide a barrier against air and moisture. The different types include: 1) Kraft paper facing, which is a strong, absorbent paper used for general purposes; 2) Glassine facing, a thin, glossy paper with good water resistance; 3) PE-coated facing, where a layer of polyethylene is applied for enhanced water resistance; 4) Aluminum foil facing, which is a thin layer of aluminum for superior barrier properties; 5) Silicone-treated glass fabric, offering high-temperature resistance and used in high-performance applications. Each type has unique properties affecting their use in various applications.</p>

- Q: Is it possible to use aluminum foil facing as a substitute for a roasting pan?

- <p>While aluminum foil facing can be used in some baking situations, it is not recommended to use it as a direct substitute for a roasting pan. Aluminum foil is not designed to withstand the high temperatures of a roasting process and can melt or warp, leading to uneven cooking and potential safety hazards. A proper roasting pan is made to handle high heat and distribute it evenly, ensuring that your food cooks properly. For best results and safety, use a designated roasting pan or a baking sheet with a higher heat tolerance.</p>

- Q: This question asks for a list of various types of aluminum foil facing that can be found in the market.

- <p>There are several types of aluminum foil facing available in the market today, including: 1. Standard Aluminum Foil Facing, which is the most common type used for insulation and moisture protection. 2. Reinforced Aluminum Foil Facing, which is stronger and more durable, often used in high-temperature applications. 3. Embossed Aluminum Foil Facing, which has a textured surface for improved aesthetics and grip. 4. Coated Aluminum Foil Facing, which is coated with materials like polyethylene for added protection against chemicals or moisture. 5. Perforated Aluminum Foil Facing, which has small holes for ventilation or drainage. 6. Laminated Aluminum Foil Facing, which combines aluminum with other materials for enhanced properties. These types cater to various applications in construction, food packaging, and other industries.</p>

- Q: Can aluminum foil be used as a surface for making pizza crust?

- <p>Yes, you can use aluminum foil facing to make a pizza crust. It's a convenient and non-stick surface that allows the crust to bake evenly and prevents it from sticking. Simply prepare your pizza dough and place it on a piece of aluminum foil sprayed with cooking oil or lined with a silicone mat. Bake according to your pizza recipe, and the aluminum foil will help create a crispy crust.</p>

- Q: What are the negative effects on the environment when aluminum foil facing is utilized?

- <p>The environmental impacts of using aluminum foil facing include increased waste generation due to its non-biodegradable nature, leading to landfill accumulation. Aluminum production is energy-intensive, contributing to greenhouse gas emissions. Additionally, improper disposal can lead to water and soil contamination. Recycling rates for aluminum are high, but not all foil is recyclable, and the process itself consumes energy. Overall, aluminum foil facing can have significant environmental consequences if not managed responsibly.</p>

Send your message to us

Aluminum Foil Facing Fiberglass Wool Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords