Aluminium Open Cell Ceiling Tiles for Buildings and Houses

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

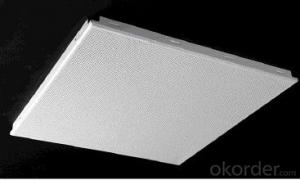

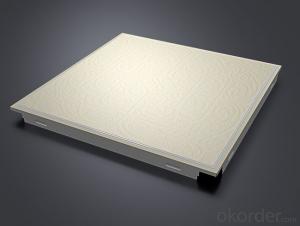

Product: Aluminum Ceiling Tiles

Material: Aluminum sheet

Thickness: 0.45-1.0mm

System: Metric or British System

Model: Clip in, Lay in, Lay on

Edge height: 8mm, 10mm, 18mm

Surface: Powder coating, Pre-paint

Perforation: Perf. 1.8mm, 2.3mm

NRC: 0.5~0.65

CAC: 30~40

Fire proof: B1

Function: Fireproof, Heat Insulation, Moisture-Proof, Mould-Proof, Sound-Absorbing, Soundproof, Waterproof

Feature: Artistic Ceilings, Integrated Ceilings, Perforated Ceilings

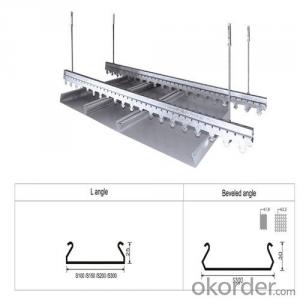

EASY PLENUM ACCESS

The panels can be easily demounted by hand allowing easy and full access to services and installation in the plenum.

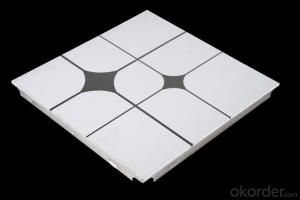

DESIGN FLEXIBILITY

Aluminum ceiling panel appearance provides interesting possibilities for spatial room designing.

The ceiling panel show different style pattern and shape, which engage you match your design.

A range of colors and finishes is standard available and special colors upon request.

DURABILITY

Square panel ceilings are manufactured from durable roll formed aluminum (0.5/0.6mm) or steel 0.5 mm coil, finished with a polyester paint to provide a long, low maintenance life. The coating is stove-enamelled in a continuous coil coating process ensuring uniform coating thickness and absolute adhesion.

PRODUCT CHARACTERISTIC

1) Surface smoothness and easy cleaning ;

2) Flexible suspension system makes each ceiling tile easily installed and disconnected;

3) Easy to match lamps or other ceiling parts;

4) Surface color can be stable for 10 years by indoor use;

5) Function: Acoustical, Fireproof, Waterproof, Washable, Light reflect.

- Q: What is the keel of aluminum alloy integrated ceiling?

- Large keel with light steel keel, small keel with aluminum alloy light steel keel will do, according to the decorative panel selection of small keel type. Generally there is a matching.

- Q: Bathroom aluminum-plastic ceiling degumming how to do?

- Even if they use glue, it is possible because the water vapor and moisture again open plastic, the best way is to use a small screw on the top. No other way, in addition to the ceiling, it can only do so, to measure, the loss of doing so the smallest.

- Q: How to distinguish between the integrated ceiling aluminum plate girders good or bad

- Factory strength ????? Before you choose a brand of buckleboard before the best understanding of the strength of the brand, the strength of the manufacturers have R & D, production and sales capabilities, which from the one hand, the quality of the brand buckle board, imagine a no R & D strength, How can a business produced by OEMs guarantee the quality of the product?

- Q: How to remove the ceiling of the aluminum plate

- Go to the supermarket to buy a sucker-style stick hook, respectively, four horns can be taken down

- Q: What is the best sticky glue?

- Hello, generally better with glass glue.

- Q: Aluminum buckle plate can be installed into a ceiling of Yuba it

- A 30cm * 30cm aluminum plate, 1.2mm thick, good quality of our price of a 5.5 yuan or so. Plus accessories (I use the Oplone, good quality) a flat about 90 blocks

- Q: Bathroom ceiling plate ceiling from the ceiling is the smallest number

- And no distance above it does not matter, the height of the bathroom you keep between 2.2 meters to 2.4 meters for the best size. Too high winter yuba heating is not to force. Too low a sense of space to suppress!

- Q: It is best to explain the method, first thank you all

- After the ceiling can not be loaded arm up and down the type of drying rack, but can be installed fixed clothes. General integrated ceiling are from the window to find the lowest point, most of the height of 2.4 meters, lower than the integrated ceiling 20 - 30 cm, across the balcony on both sides of the wall fixed a stainless steel dry clothes on it.

- Q: Precautions for the purchase of aluminum slabs

- And aluminum slab board installation and often need to install with other products, many owners in the installation of aluminum slabs that day will be related to the installation of the relevant products to the scene, even when found in the accessories were businessmen deceived, and only had to eat this dumb The

- Q: How to distinguish between PVC plastic gussets and aluminum gussets?

- In the use of performance: PVC plastic buckle water, scrub resistance is very strong, compared to the lower cost. Aluminum gusset plate in the texture, decorative sense of the better First, PVC plastic gusset to PVC as raw material, light weight, easy to install, waterproof, anti-borers, the surface color pattern changes are also very much, and resistant to pollution, good cleaning, sound insulation, good heat insulation, especially the new The process by adding flame retardant materials, so that it can fire that is off, the use of more secure. The downside is compared with the metal plate. Life is relatively short. Second, the aluminum gusset plate compared with the traditional ceiling material, texture and decorative sense of the better As the thermal insulation properties of metal plate is poor, in order to obtain a certain sound absorption, adiabatic function, in the choice of metal plate ceiling decoration, you can use the addition of glass wool, rock wool and other insulation materials to achieve the effect of adiabatic sound absorption.

Send your message to us

Aluminium Open Cell Ceiling Tiles for Buildings and Houses

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords