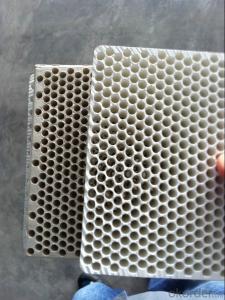

Alumina Ceramic Rod Ceramic Filter Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

alumina ceramic parts

1.Material: High purity alumina

2.Processed by cold-pressing

3.QA,rush delivery

4.MOQ:500pcs

Name | Unit | Alumina | Zirconia | ||

Content | % | ≥95 | ≥99 | ≥99.7 | ≥94 |

Density | g/cm3 | 3.60 | 3.90 | 3.90 | 6.00 |

Hardness (Hv0.5) | GPa | 13.1 | 15.0 | 17.1 | 13.2 |

flexural strength

| MPa≥ | 340 | 310 | 370 | 1000 |

Elasticity | GPa | 300 | 330 | 350 | 200 |

Poisson's ratio

|

| 0.23 | 0.23 | 0.23 | 0.30 |

Max Tem. | °C≥ | 1400 | 1750 | 1800 | 1050 |

Heat expansion | ×10-6/°C(40-800°C) | 7.8 | 8.0 | 8.0 | 11.0 |

Thermo conductivity

| W/m·K( 20°C) | 22 | 28 | 31 | 2.6 |

Thermal Resistance | °C | 200 | 200 | 230 | 300 |

dielectric strength

| V/m | 15×106 | 15×106 | 15×106 | 11×106 |

dielectric phase angle (1MHz) | ×10-4 | 4 | 2 | 1 | 16 |

SIC(1MHz) |

| 9.2 | 9.8 | 9.9 | 33 |

Nitric Acid (60%)90°C | WT Loss mg/cm2/day≤ | 0.12 | 0.10 | 0.05 | ≠0 |

Sodium hudroxide (30%)80°C | WT Loss mg/cm2/day≤ | 0.53 | 0.26 | 0.04 | 0.08 |

- Q: How many degrees does the ceramic filter melt?

- Alumina made from tabular corundum can be used over 1800 degrees!SiC if there is atmosphere, protection will be higher, there is no atmosphere protection, because the existence of oxidation, generally not more than 1600.Corundum, mullite, 1750 degrees small meaning.

- Q: Ceramic filter in vacuum pressure enough, the ceramic plate does not suck pulp, what is the reason for analysis?

- The incoming mud content, fine particle size, pulp itself is not suitable for the use of ceramic filter dehydration, if the use of ceramic filter dehydration in this case, will accelerate the blockage of ceramic filter plate, blocking the situation after the second reference description.

- Q: Ceramic filter fineness thin mud suction is not what to do more

- With ceramic filter to treat pulp dehydration, the particle size is too large, the particles are easy to precipitate, the particle size is too small, too much mud, then the water content of the filter cake will increase, and the life of the ceramic filter plate will be reduced.

- Q: What is the working pressure of the ceramic filter?

- Vacuum pressure or suction is the vacuum of the equipment, the size of the vacuum directly affects the effect of ceramic filter board suction (yield and water content). The vacuum system of ceramic filter consists of vacuum pumps, tanks, distribution device, ceramic filter plate and a connecting pipe is composed of ceramic filter, the vacuum pump is generally 2BV series water circulation pump, the vacuum pump vacuum limit is -0.097MPa, using a vacuum pump for a long time or vacuum system has poor sealing performance may cause a certain degree of vacuum distortion, so the ceramic filter vacuum is generally difficult to achieve in the -0.097MPa, -0.08 ~ 0.097MPa, which indicates that the vacuum degree is good, such as the vacuum degree is not up to -0.07MPa or less, the vacuum system may be an exception.

- Q: Ceramic filter capacity.

- 60 square meters of ceramic filter power 35kW or so, a high degree of automation, each class can complete the operation.

- Q: Ceramic filter cleaning, sulfuric acid cleaning

- Ceramic filter medium is ceramic, ceramic generally resistant to strong acid, alkali, cleaning, it is best to use nitric acid, hydrochloric acid next, not recommended to use sulfuric acid.

- Q: Excuse me, what's the reason that all ceramic filters do not attract ore?

- After the joint cleaning, 0~2 hours of suction effect may be good, 2~4 may drop slightly, 4 hours later will become worse and worse, or even suck. This case should first check the backwash water pressure (instantaneous maximum pressure should not be less than 0.08MPa) is to meet the requirements, should also advance down (to ensure normal and ultrasonic cleaning combined with nitric acid dosage sufficient) and prolong the cleaning time.

- Q: What's the acid of the ceramic filter plate?

- General ceramic filter running for eight hours or so, you need to stop for joint cleaning, general cleaning at an hour or so. When washing together, there is acid washing, usually concentrated nitric acid. The purpose is to dissolve the pores in the ceramic filter plate through nitric acid.

- Q: What are the reasons for the program alarm of ceramic filter?

- If you say "lean" is the ceramic filter suction when the ceramic filter plate into a cake of thin, high water content, is the ceramic filter for their own reasons, can from the following aspects: the investigation considering this phenomenon is always so recently or just happened, if you have been so, probably because your selection is not suitable for pulp the ceramic filter (such as mud content, fine grain size, ceramic filter plate selection such as inconsistent or unqualified ceramic filter). If this anomaly has occurred recently, it is possible to change the ore condition, and the operation parameters of ceramic filters or the cleaning are not up to standard. You can check the vacuum system (vacuum generally ranges from -0.09 to -0.075MPa), backwashing system (generally refers to the filtered water recoil 0.07 ~ 0.12MPa), acid (HNO3 system standards), ultrasonic system is normal.

- Q: What is the reason that the whole ceramic filter does not attract ore?

- After the joint cleaning, 0~2 hours of suction effect may be good, 2~4 may drop slightly, 4 hours later will become worse and worse, or even suck. This case should first check the backwash water pressure (instantaneous maximum pressure should not be less than 0.08MPa) is to meet the requirements, should also advance down (to ensure normal and ultrasonic cleaning combined with nitric acid dosage sufficient) and prolong the cleaning time.

Send your message to us

Alumina Ceramic Rod Ceramic Filter Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords