Alu Alu Foil alu45-65micron for Blister Packaging

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specification

WIDTH | THICKNESS ( MICRON) | TOTAL THICKNESS | CORE SIZE | ROLL LENGTH | MOQ | ||||||||

OPA | AL | PVC | |||||||||||

≤600mm | 25 | 45-65 | 60 | 130-165um | 76mm | 240-280m | 0.2MT | ||||||

PACKING | Inner packing: each roll to be wrapped with sack polyethylene. Outer packing:carton packing,wrap by film then pallet packing. | ||||||||||||

Function | A high obstruction, A high photophobic, good oxygen resistance, moisture proof, forming, Improve packaging grades and to extend product shelf life |

Character 1 | Construct agglutination is strong not easy to layered or open |

Character 2 | Take some content of tablets, NO impact on the same other well-packed medicinal parts |

Character 3 | Tested by a 30-um pinhole, completely avoid minor damages that can not tested by eyes |

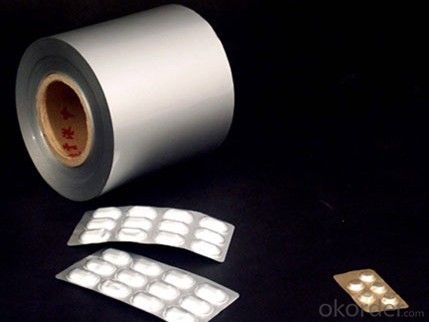

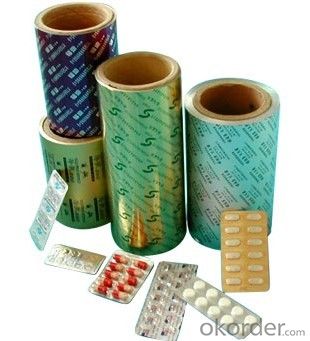

Application | Gels, tablets, capsules, injection, the outer packaging of disposable medical devices,the inside packaging of comestic |

Remark | The primary selection for high grade medicine under extreme high or low temperature. |

2. Application:

Cold Forming Blister Aluminum Foils can resistance to moisture, gasses and UV Ray, provide the utmost protection for medical products with strict protection requirements.

3. Advantages:

It is commonly used for medicines, medical equipments and diagnostic products packing. It could be used base on the product packing sizes, the stretch of AL/Plastic composite measure, and the performance of cold formable to handle any forming blister.

4. Pictures:

5.FAQ:

How about delivery time?

40~50 days.

How about MOQ?

One ton per size.

What's the payment term ?

100% irrevocable LC at sight or 30% / 20% advance balance TT against BL copy.

- Q: What is aluminum foil?Direct rolling with metallic aluminium

- A metal foil: Aluminium directly rolled into sheets of hot stamping material, the effect of stamping and silver foil stamping similar effects, it is also called the false. Because of its soft texture and good ductility, it has a silvery luster. If the rolled sheet is made of sodium silicate on the offset paper, the foil can be printed. But the aluminum foil itself is easy to oxidize and the color is dull, friction, touch and so on will fade. Therefore, it is not suitable for the long-term preservation of books, covers and other hot stamping.

- Q: With aluminum foil wrapped 0.1mol metal sodium in water by needle konza a plurality of small holes, after complete reaction, the volume of gas released (standard) (for)A. cannot determine that B.1.12L C. is greater than 1.12L and D. is less than 1.12L

- 0.1molNa fully reacts to generate V (H 2), =2n (Na),.V, m, =2 * 0.1mol * 22.4L/mol=4.48L > 1.12L,So choose C.

- Q: How can I clean the aluminum foil products when they are punched out?

- Quenching oil cold? The same oil, ah, the supply of this quenching cooling oil companies generally sell their corresponding cleaning agent. Just pay attention to the influence of cleaning agent on aluminum products.

- Q: Aluminum foil surface, SBS roll multilayer superposition, waterproof effect is good?

- Generally speaking, SBS waterproofing membrane superimposed use, will certainly be better than the use of single layer. But the first time with the construction of aluminum thread with a little waste. Because aluminum Bu in coil plays only a reflective insulation function, so if the two house the first time it is not necessary to use the superposition with aluminum Bu, PE film can be second times, and then the aluminum coil Bu

- Q: What is the material of aluminium foil yogurt cover?

- The utility model can be characterized in that the utility model has the advantages of ensuring shading, no falling, no light transmission, no pollution, and low price.

- Q: Can screen printing be made on aluminum foil? What are the requirements for various specifications such as process and printing ink and printing thickness?

- First on the substrate test print, first confirm whether attached, if the attachment is not ideal, you can add 0.5 grams / kg: butyl acetate.

- Q: What is a composite aluminum foil molded poly vinyl foam board, and what is a composite aluminum foil extrusion poly vinyl vinyl insulation board, the two how to distinguish?Please try to be more specific

- A kind of composite heat preservation board with aluminum foil is used in air conditioning and air duct insulation1, the insulation material molded type insulating materials used is moulded polystyrene foam board, also known as EPS, commonly used household appliances packaging materials is the white foam foam board; the extruded insulation material is extruded polystyrene foam board, which is XPS.

- Q: The difference between pure aluminium foil bags and aluminium plated bags

- Three, from the performance point of view, pure aluminum bags moistureproof, cooling effect better than aluminum bag, pure aluminum bag completely avoid light, aluminized bag is shading effect.Four, from the use, the pure aluminum bag is more suitable for vacuum pumping, such as food, meat and other products, while the aluminum plated bag suitable for tea, powder, electronic and other pieces.Five, the inside of the bag facing the light or sunlight, can see through the bag of light is plated aluminum foil, invisible is pure aluminum foil

- Q: When the wire is made, it needs a layer of foil inside, and the outside is insulated. Why is that?

- Shield used as a cable. The cable foil requires less oil on the surface and has no holes. It has high mechanical properties, but the overall quality requirements are not high, but the requirements of the length are very strict.

- Q: Black shading and shading of the aluminum foil machine what is the difference

- A set of yarns or sets of yarns arranged parallel to all the work needles fed into the machine,

Send your message to us

Alu Alu Foil alu45-65micron for Blister Packaging

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords