2024 New Factory Manufacture PVC Foam Board Machine for Plastic Sheets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

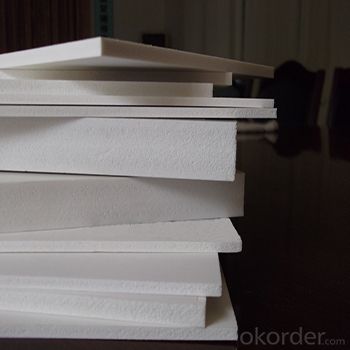

Features

1. Waterproofing.

2. Fire retardant and self-extinguishing.

3. Heat preservation.

4. Sound-insulated and Insulation. .

5. Dampproof and Anti - deformed.

6. Non-corrosion and Non-toxic.

7. Tough, rigid with the high impact strength.

8. Stable color retention.

Specifications:

1 Width: 1220mm or as your requirement

2 Length: 2440mm or as per your requirement

3 Thickness: From 1mm to 30mm

4 Density: from 0.3 to 0.6

Applications:

1. Building outdoor wall board, indoor decoration board, partition board in office and house.

2. Screen printing, flat solvent printing, engraving, billboard and exhibition display.

3. Chemical anti corrosion project, special cold project, environmental protection.

Parameter

| Products Name | pvc foam board machine |

| Main Material | PVC powder |

| Surface Treatment | As per your request |

| Color | White and so on |

| Certificate | SGS,3C,RoHs, ISO |

| Payment | 30% deposit, 70% balance before shipment. T/T W/U M/G |

| Packing | Carton box or wooden pallet packing. |

FAQ:

Q1: What are your product ranges? Where is your market?

A1: we are manufacturer specializing in stationery and plastic packing products in highly quality

and competitive price with over years,such as file folder,file bag,gift bag,closet organizer ,

packages of cosmetic and other daily necessities.

Q2: If the products have some quality problem ,how will you deal with it?

A2: If the quality problem caused by us, we will provide a replacement service,and we must keep in mind. Take measures to control quality strictly,we adhere to the principle: “ quality first”.

Q3: Is free design assistance available for clients?

A3: If you have problems in designing or beautifying the customized product, we will offer you the best design assistance.

Q4: What factors affect the price?

A4: Style, material, dimension, quantity, logo etc.AS for your inquiry, try to give us all these information toget exact quotation.

- Q: Can plastic sheets be used for medical or healthcare purposes?

- Yes, plastic sheets can be used for medical or healthcare purposes. They are commonly utilized in hospitals and healthcare facilities for various applications such as protective barriers, disposable coverings, isolation curtains, wound dressings, and medical packaging. Plastic sheets provide a flexible, lightweight, and cost-effective solution for ensuring hygiene, preventing infection, and maintaining a sterile environment in medical settings.

- Q: is the smell of new sheets/comforters harmful? Do I have to wash before use or is it ok right out of plastic?

- It is best to wash them, not because of the smell but because of the chemicals (often sprays are used post-production to avoid infestation), as well as those used to grow the cotton or make the other fibers. *** NOTE FOR SENSITIVE PEOPLE: You can get rid of some finishes if you soak the item 2 to 6 hr. in machine full of water w. a cup of white vinegar, rinse and then wash in machine w. half cup baking soda (no soap). *** If you buy organic, you avoid the entire issue. Aso, keep the water cool or warm, not hot, and be sure item is colorfast. If you are not sure, be safe and just wash as directed on the packaging.

- Q: Anyone know where a good place to find something like this is? Basically I need a 1/2 piece thick sheet that is 10 ft by 18ft or possible two 5 x 9 ft. pieces.

- TRY HOBBY LOBBY,MICHAIL'S OR THE RAG-SHOP

- Q: How thick are plastic sheets typically?

- Plastic sheets can vary in thickness depending on their intended use, but they typically range from 0.25 millimeters to 6 millimeters.

- Q: i'm looking for some clear plastic sheets (similar to laminating) that i can use a dry erase markers on and place over the whiteboard in my classroom - for putting music notes on the staff etc.i don't want to rewrite them over and over. since there is no laminator in my school, i am at a loss for what to use. of course i can by laminating rolls. anything else i can use and where to get it?

- Use Plexiglas. You can buy it at a hardware store in various sizes and thicknesses. It is also cheap.

- Q: Can plastic sheets be used for skylights?

- Yes, plastic sheets can be used for skylights. They are a popular alternative to glass due to their durability, lightweight nature, and cost-effectiveness. Plastic sheets such as polycarbonate or acrylic are commonly used as they offer excellent light transmission, high impact resistance, and UV protection. These materials are also available in different colors and thicknesses, making them suitable for various skylight applications.

- Q: Are plastic sheets safe for food contact?

- Yes, plastic sheets that are specifically designed and certified for food contact are safe to use.

- Q: imagine with mei want one side to be plastic to see whats happening insideand the other 3 sides is iron sheetits a straight duct ,,, no anglesvolume of the duct = 0.35 x 0.35 x 2.5a professor told that the best thickness for plastic side is 3mmand the iron sheet is 0.6mmis that right??if it is wrong tell me the best thickness for both??

- would increase the thickness

- Q: What are the disadvantages of using plastic sheets?

- Some of the disadvantages of using plastic sheets include their non-biodegradable nature, which contributes to environmental pollution, their potential to release harmful chemicals when exposed to heat, their vulnerability to damage and scratching, and their limited aesthetic appeal compared to other materials. Additionally, the production of plastic sheets requires the extraction and processing of fossil fuels, contributing to climate change and resource depletion.

- Q: How many kinds of materials are extruded polystyrene foam boards?

- Polystyrene as the original heat preservation material has two kinds, one is the Extrusion board, and the other is polystyrene board, the most used is the Extrusion board, polystyrene board has not much use, flame retardant performance to less than B1 class,

Send your message to us

2024 New Factory Manufacture PVC Foam Board Machine for Plastic Sheets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords